Nissan Rogue (T33) 2021-Present Service Manual: Type a :: Basic Inspection

Meter, Warning Lamp & Indicator

Diagnosis and Repair Workflow

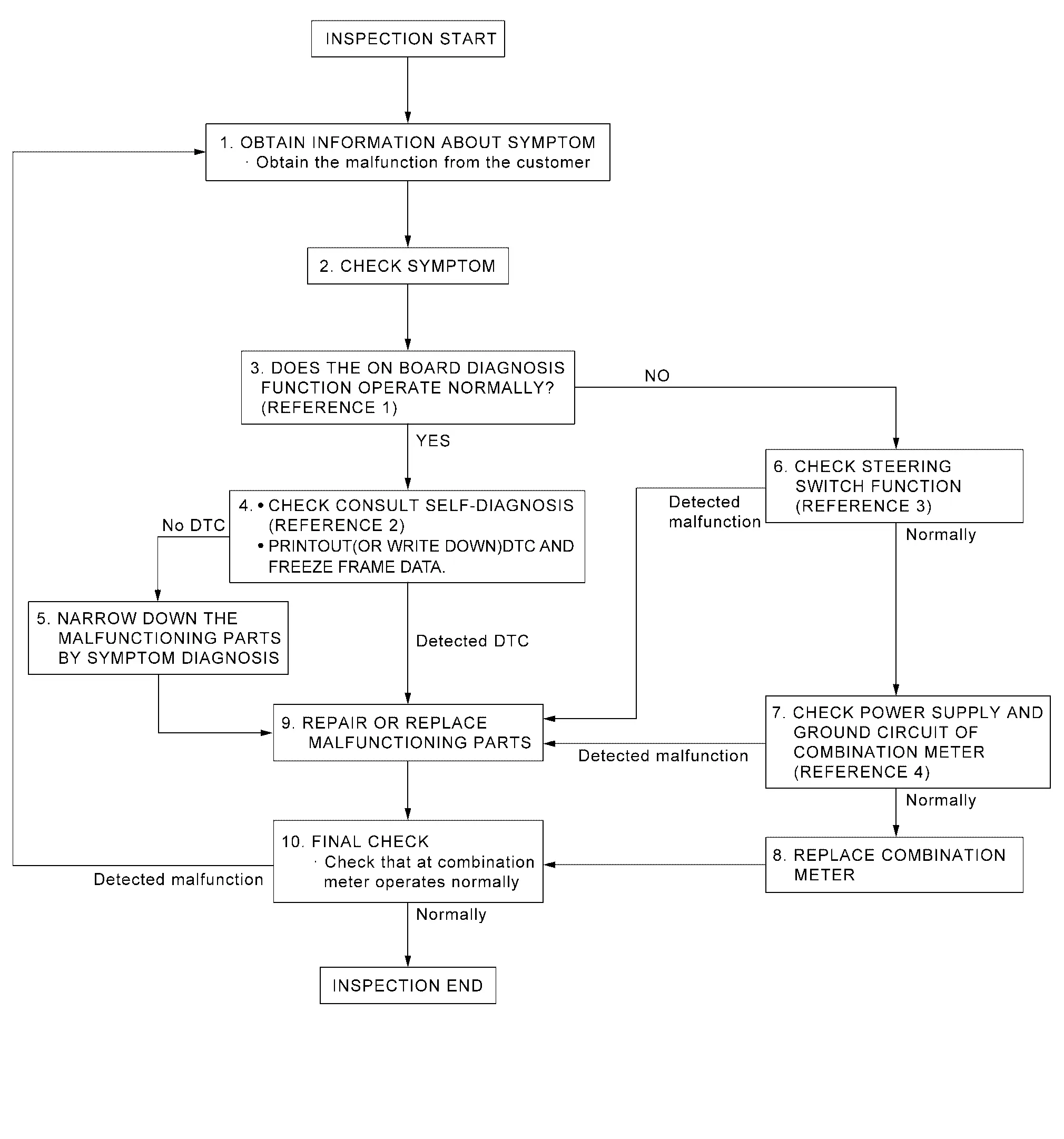

Work flow

OVERALL SEQUENCE

-

Reference 1ôñôñôñOn Board Diagnosis Function.

-

Reference 2ôñôñôñDTC Index.

-

Reference 3ôñôñôñComponent Function Check.

-

Reference 4ôñôñôñDiagnosis Procedure.

DETAILED FLOW

OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>>

GO TO 2.

CHECK SYMPTOM

-

Check the symptom based on the information obtained from the customer.

-

Check that any other malfunctions are present.

>>

GO TO 3.

CHECK ON BOARD DIAGNOSIS OPERATION

Check that the on board diagnosis function operates. Refer to On Board Diagnosis Function.

Does the on board diagnosis function operate normally?

YES>>GO TO 4.

NO>>GO TO 6.

CHECK CONSULT SELF-DIAGNOSIS RESULTS

CONSULT

CONSULT

-

Perform self-diagnosis. Refer to DTC Index.

-

When DTC is detected, follow the instructions below:

-

Record DTC and Freeze Frame Data.

-

Are self-diagnosis results normal?

YES>>GO TO 5.

NO>>GO TO 9.

NARROW DOWN THE MALFUNCTIONING PARTS BY SYMPTOM DIAGNOSIS

Perform symptom diagnosis and narrow down the malfunctioning parts.

>>

GO TO 9.

CHECK STEERING SWITCH FUNCTION

Check steering switch function. Refer to Component Function Check.

Is inspection result normal?

YES>>GO TO 7.

NO>>GO TO 9.

CHECK COMBINATION METER POWER SUPPLY AND GROUND CIRCUITS

Check combination meter power supply and ground circuits. Refer to Diagnosis Procedure.

Is inspection result normal?

YES>>GO TO 8.

NO>>GO TO 9.

REPLACE COMBINATION METER

Replace combination meter.

>>

GO TO 10

REPAIR OR REPLACE MALFUNCTIONING PARTS

Repair or replace the malfunctioning parts.

NOTE:

NOTE:

If DTC is displayed, erase DTC after repair or replace malfunctioning parts.

>>

GO TO 10.

FINAL CHECK

Check that the combination meter operates normally.

Do they operate normally?

YES>>Inspection End.

NO>>GO TO 1.

Additional Service When Replacing Combination Meter

Work Procedure

DESCRIPTION

When replacing the Combination meter, perform the procedures before and after replacement.

Before Replacement

Take note the odometer mileage of the combination meter. When replacing the combination meter, check that DTCãs are not detected at ãSelf diagnosis resultã of ABS. When detecting DTCãs, perform ãSelf diagnosis resultã of ABS.

After Replacement

After replacing the combination meter, the following items must be performed.

-

Configuration

-

Actual driving 0.6 mi (1 km) or more

NOTE:

NOTE:

The odometer mileage of the combination meter is also stored and memorized in the ABS actuator and electric unit (control unit). When driving 0.6 mi (1 km) or more after replacement of the combination meter, the memorized mileage in the ABS actuator and electric unit (control unit) is writed into the new combination meter.

WORK PROCEDURE

COMBINATION METER CONFIGURATION

CONSULT

CONSULT

Perform the combination meter configuration. Refer to Work Procedure.

>>

GO TO 2.

PERFORM SELF-DIAGNOSIS

CONSULT

CONSULT

Select ãSelf diagnosis resultã of combination meter. Check if any DTC is detected.

Is any DTC detected?

YES>>Perform the trouble diagnosis for the detected DTC. Refer to DTC Index.

NO>>GO TO 3.

DRIVING TEST

Drive the Nissan Ariya vehicle on the road 0.6 mi (1 km) or more.

Check that the odometer shows more than the mileage taken note before.

>>Inspection End.

Configuration (combination Meter)

Description

Vehicle specification needs to be written with CONSULT because it is not written after replacing the combination meter.

The configuration requires network connection. CONSULT connects to network and then it downloads the configuration data from the server. Then CONSULT writes the Nissan Ariya vehicle specification to the combination meter.

Refer to Work Procedure.

NOTE:

NOTE:

For details the network connection and operation, refer to ãCONSULT Operation Manualã.

The configuration no need to ãsaveã configuration data from the combination meter. The configuration data is always generated freshly at the server and then downloaded to the CONSULT.

CAUTION:

-

Complete the procedure of ãConfigurationã in order.

-

If incorrect ãConfigurationã, incidents might occur.

-

Never perform ãConfigurationã except for new combination meter.

Work Procedure

WRITING VEHICLE SPECIFICATION

CONSULT

CONSULT

Perform writing Nissan Ariya vehicle specification to combination meter following "Automatic Configuration" procedure of "Configuration" according to CONSULT Operation Manual.

NOTE:

NOTE:

-

Log in the network according to CONSULT guidance.

-

For details the network connection and operation, refer to ãCONSULT Operation Manualã.

>>

Work End.

Head up Display

Diagnosis and Repair Work Flow

Work Flow

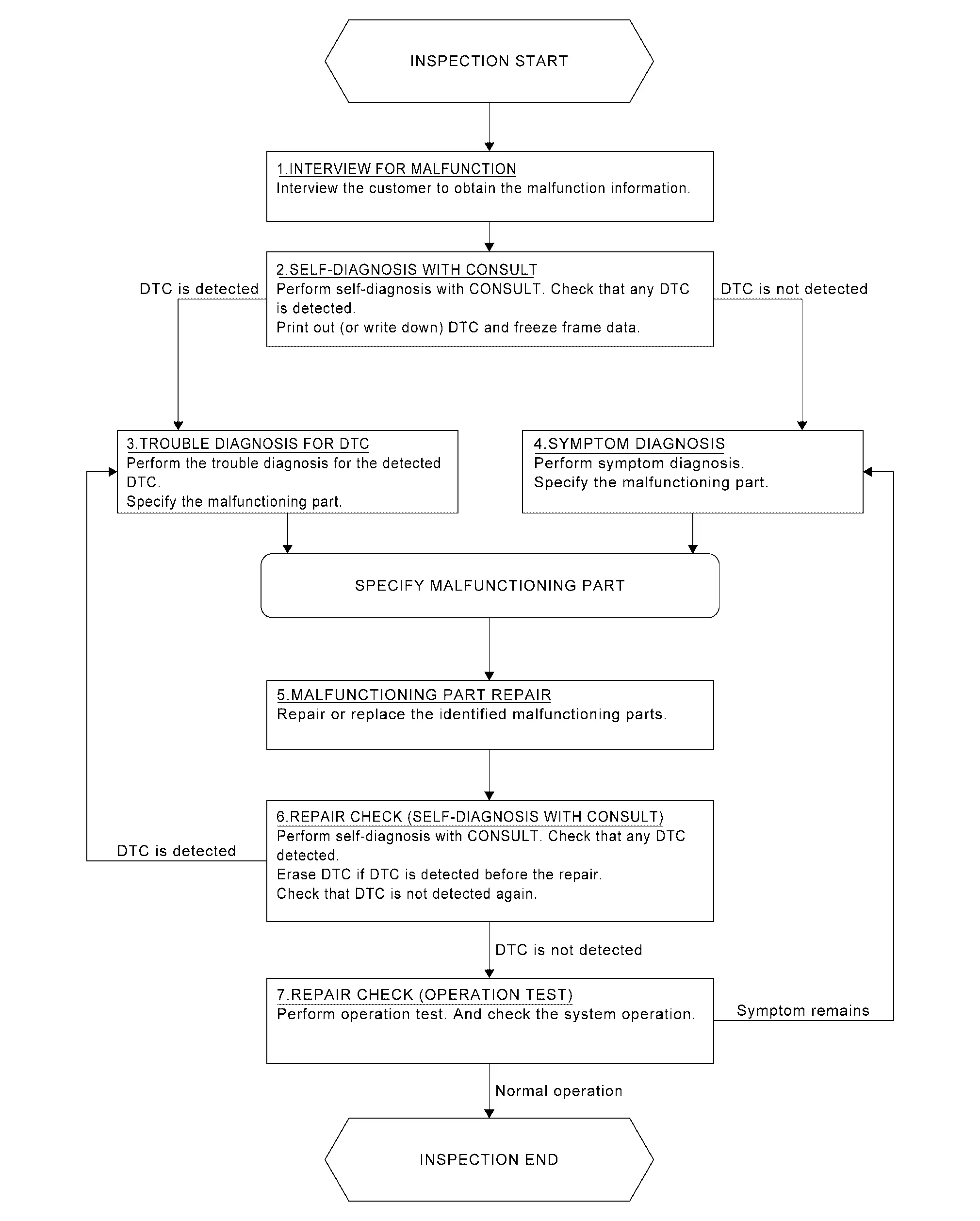

OVERALL SEQUENCE

DETAILED FLOW

INTERVIEW FOR MALFUNCTION

It is also important to clarify the customer concerns before starting the inspection. Interview the customer about the concerns carefully and understand the symptoms fully.

NOTE:

NOTE:

The customers are not professionals. Never assume that ãmaybe the customer meansôñôñôñã or ãmaybe the customer mentioned this symptomã.

>>

GO TO 2.

SELF-DIAGNOSIS

CONSULT

CONSULT

Perform self-diagnosis of ãHEAD UP DISPLAYã. Refer to CONSULT Function.

NOTE:

NOTE:

Skip to step 4 of the diagnosis procedure if ãHEAD UP DISPLAYã is not displayed.

Is any DTC detected?

YES>>GO TO 3.

NO>>GO TO 4.

TROUBLE DIAGNOSIS FOR DTC

-

Check the DTC indicated in the ãSelf diagnosis resultã.

-

When DTC is detected, follow the instructions below:

-

Record DTC

-

Freeze Frame Data (FFD)

-

-

Perform the relevant diagnosis referring to the DTC Index. Refer to DTC Index.

>>

GO TO 5.

SYMPTOM DIAGNOSIS

Perform the applicable diagnosis according to the diagnosis chart by symptom. Refer to Symptom Table.

>>

GO TO 5.

MALFUNCTIONING PART REPAIR

Repair or replace the identified malfunctioning parts.

>>

GO TO 6.

REPAIR CHECK (SELF-DIAGNOSIS)

CONSULT

CONSULT

-

Erases self-diagnosis results.

-

Perform self-diagnosis of ãHEAD UP DISPLAYã again after repairing or replacing the specific items.

-

Check if any DTC is detected in self-diagnosis results of ãHEAD UP DISPLAYã.

Is any DTC detected?

YES>>GO TO 3.

NO>>GO TO 7.

REPAIR CHECK (OPERATION TEST)

Perform operation test. Check that the malfunction symptom is solved or no other symptoms occur.

Is there a malfunction symptom?

YES>>GO TO 4.

NO>>Inspection End.

Additional Service When Replacing Head up Display Unit

Work Procedure

Description

When replacing or removing the Head Up Display unit, distortion calibration of the display and adjustment of the display position are required.

Work Procedure

REPLACE HEAD UP DISPLAY UNIT

Replace Head Up Display unit. Refer to Removal and Installation.

>>

GO TO 2.

PERFORM CALIBRATION

Perform Head Up Display calibration. Refer to Work Procedure.

>>

GO TO 3.

ADJUST DISPLAY SCREEN

Adjust display screen position. Refer to Switch Name and Function.

>>

GO TO 4.

OPERATION CHECK

Check the display of Head Up Display.

Is the displayed normal?

YES>>WORK END

NO>>Perform display adjustment again. GO TO 3.

Head up Display Calibration

Work Procedure

Description

Calibration must be performed after replacing or removing/installing the following parts:

-

Head Up Display unit

-

Windshield glass

-

Steering member

Diagnosis Procedure

NOTE:

NOTE:

-

Place the vehicle on level ground.

-

Keep the space when calibration. (Nissan Ariya Vehicle front area)

-

Wide: 2.0 m (6.56 ft)

-

Height: 2.0 m (6.56 ft)

-

Length: 2.0 m (6.56 ft)

-

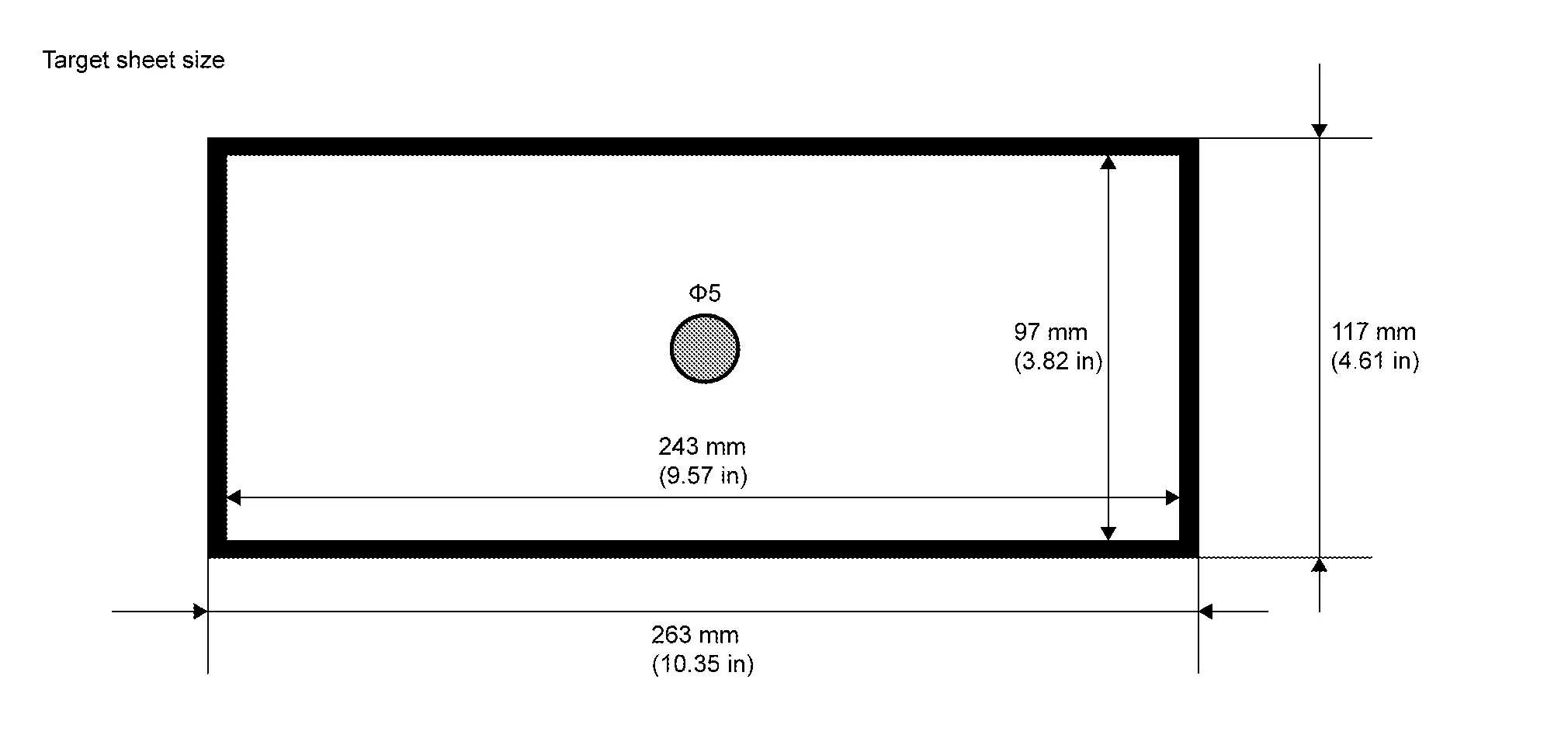

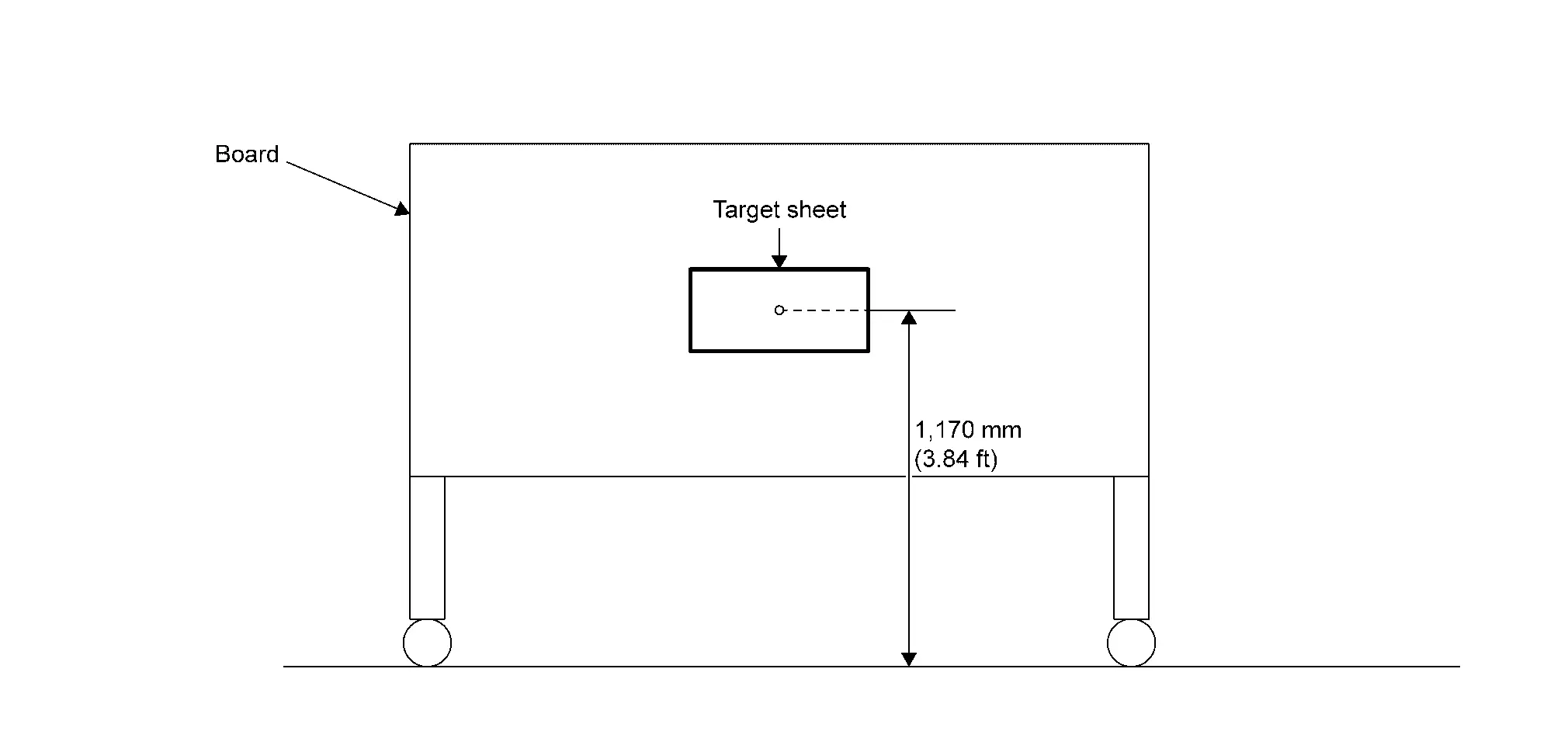

TARGET PREPARATION

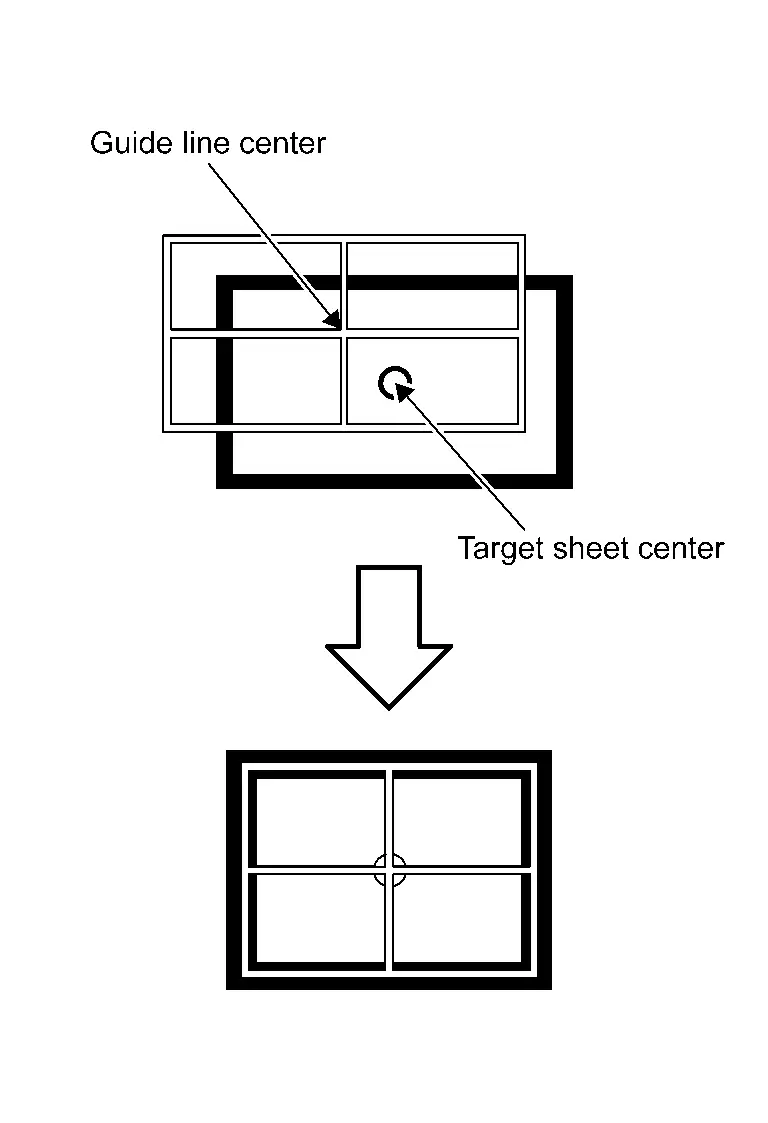

Prepare the distortion calibration jig according to the following procedure and the figure.

-

Prepare target sheet according to the figure.

-

Paste the created target sheet onto the board according to the figure.

>>

GO TO 2.

TARGET SETTING

-

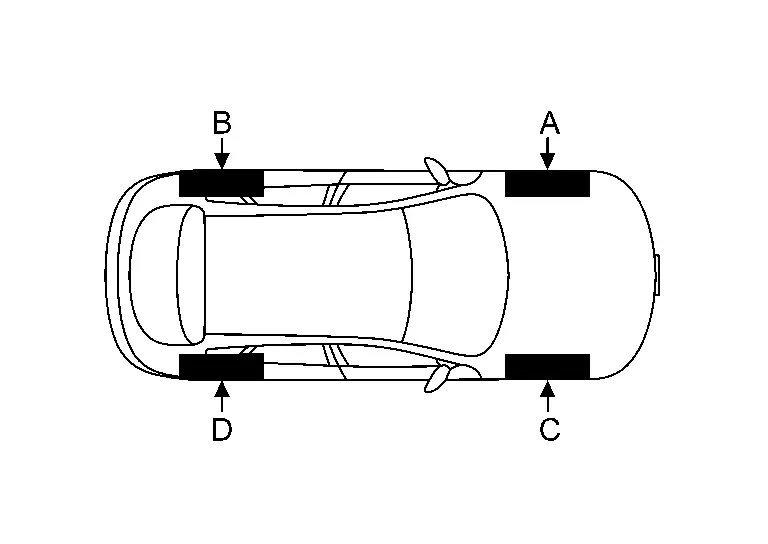

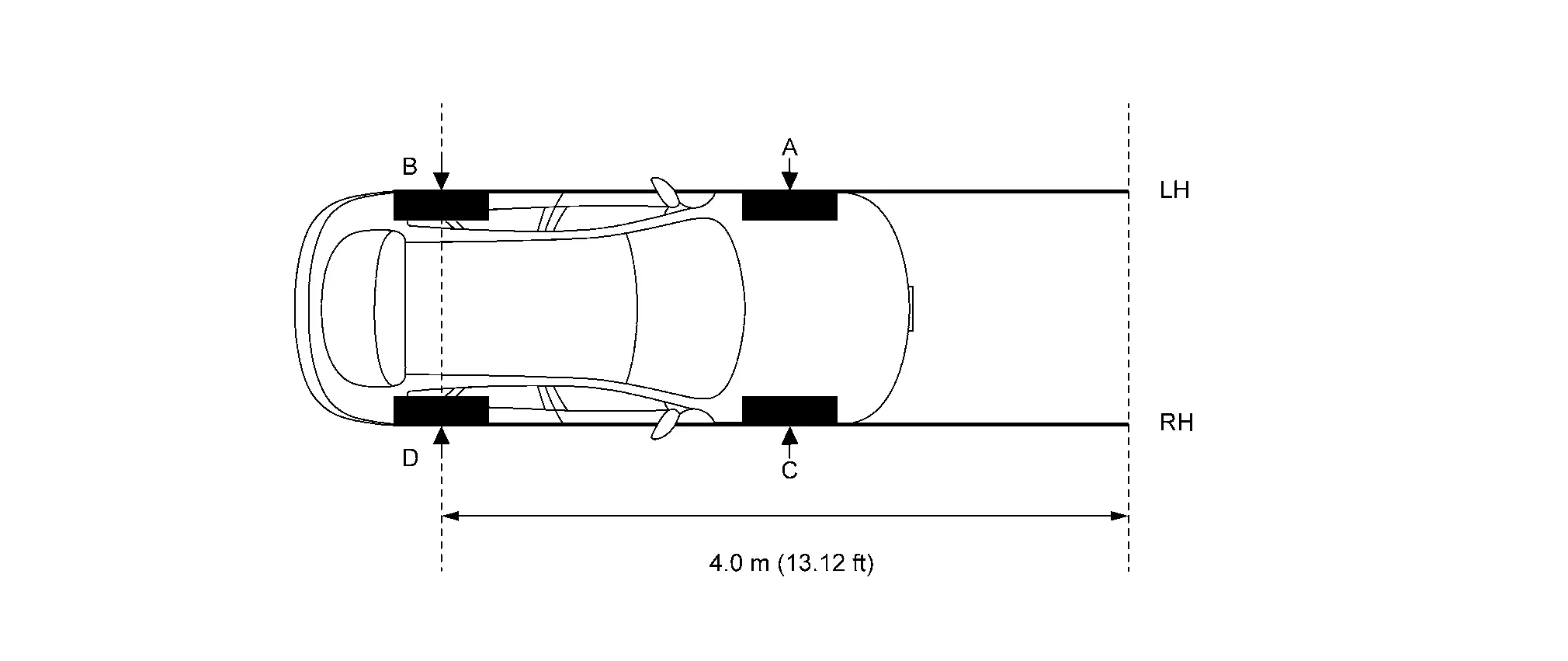

Mark points ãAã, ãBã, ãCã and ãDã at the center position of each wheels.

-

Draw line "LH (RH)" passing through points "A (C)" and "B (D)" on the left (right) side of Nissan Ariya vehicle.

NOTE:

NOTE:

Approximately 4.0 m (13.12 ft) or more from the point "B (D)".

-

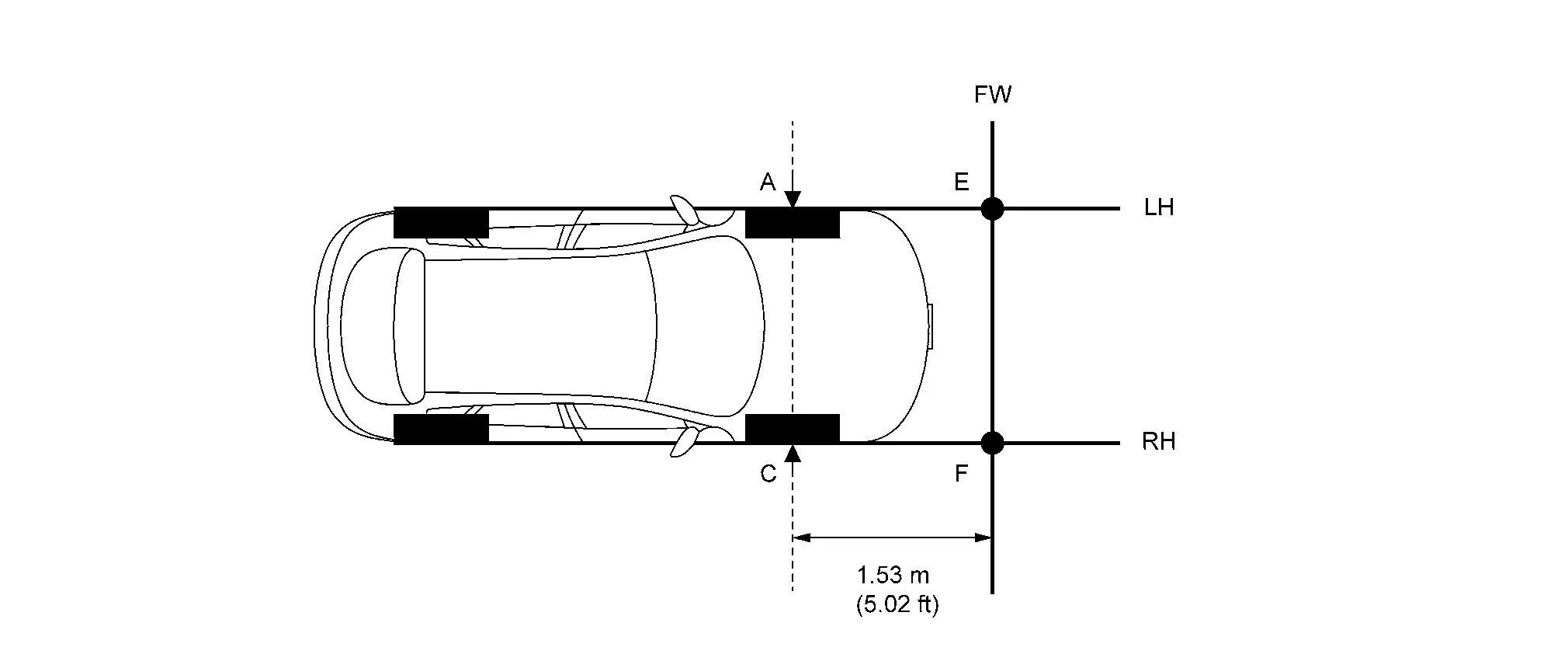

Mark point "E (F)" on the line "LH (RH)" at the positions 1.53 m (5.02 in) from point "A (C)". And then draw line "FW" passing through the points "E" and "F".

-

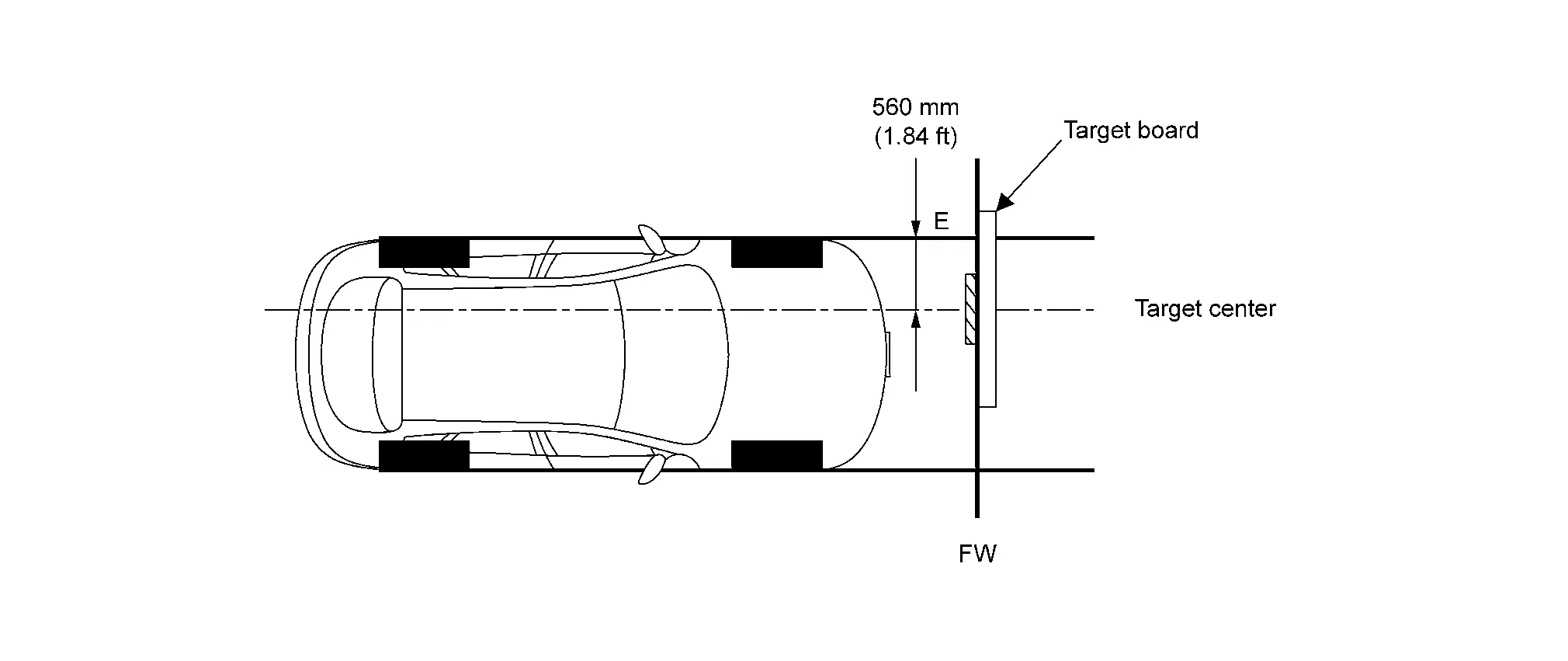

Place the target board on the line "FW" so that the center of the target comes to 560 mm (1.84 ft) from mark point "E".

>>

GO TO 3.

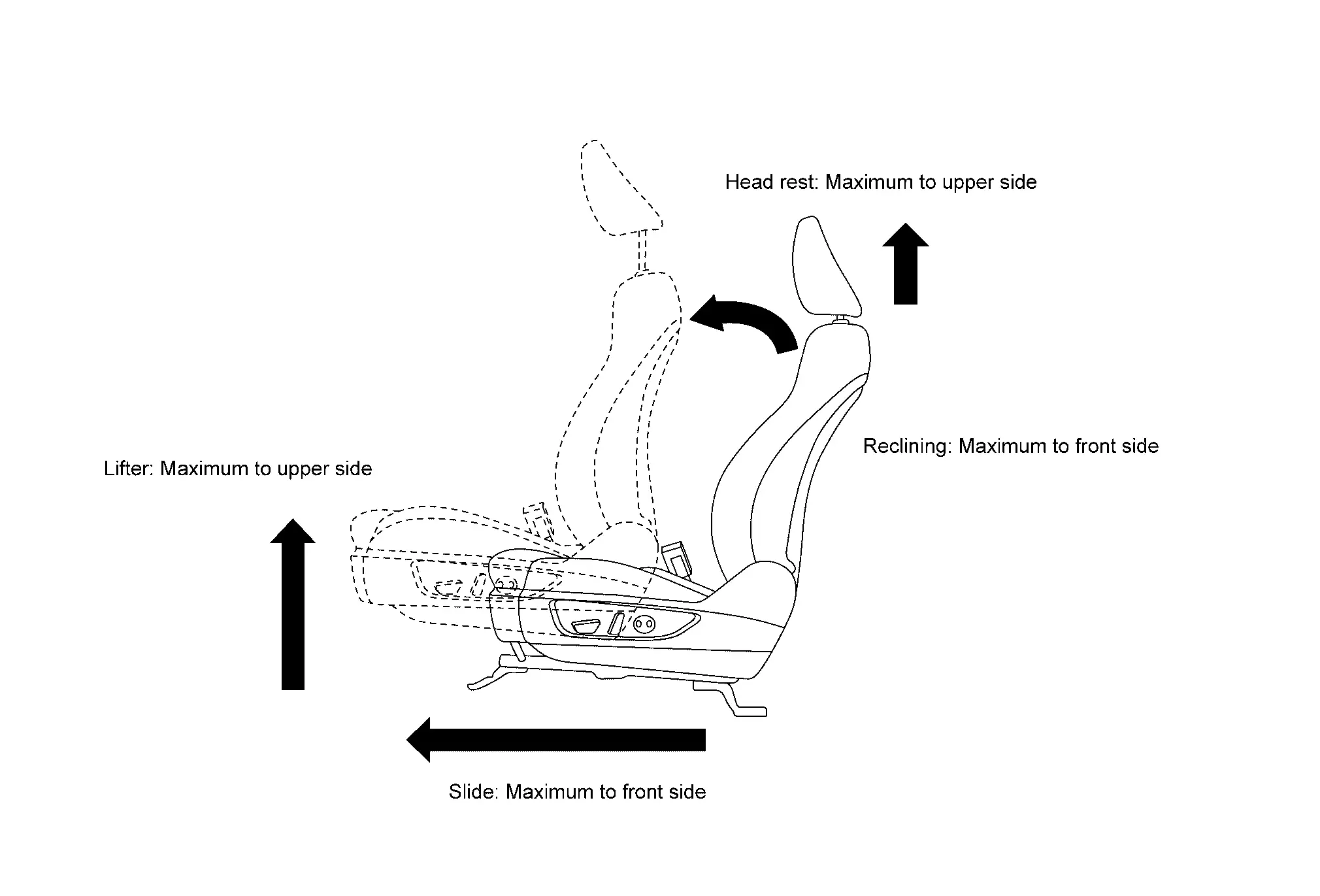

DRIVER'S SEAT POSITION ADJUSTMENT

Adjust the driver's seat to the position shown in the figure.

>>

GO TO 4.

RESET OPERATION

-

Ignition switch ON.

-

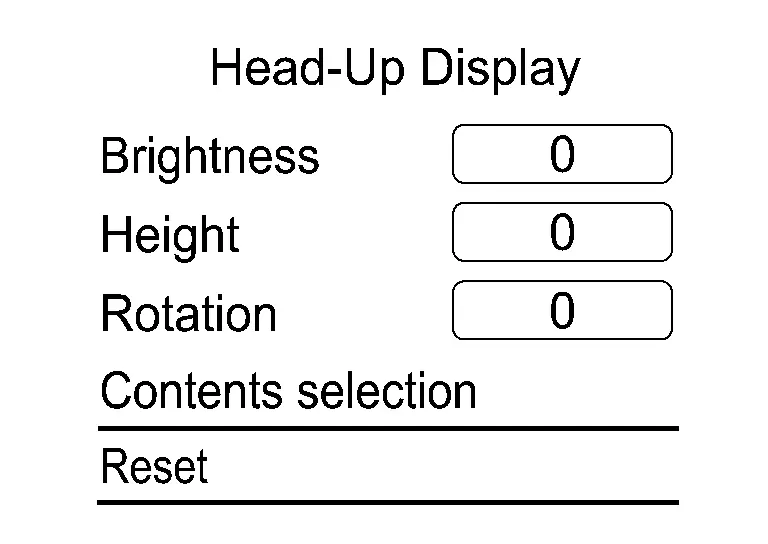

Select "Reset" on the Head Up Display setting screen of the combination meter and reset the setting. Refer to Switch Name and Function.

>>

GO TO 5.

TARGET CENTER POSITION ADJUSTMENT

CONSULT

CONSULT

-

Select "Distortion calibration" of "Work Support" on "HEAD UP DISPLAY".

-

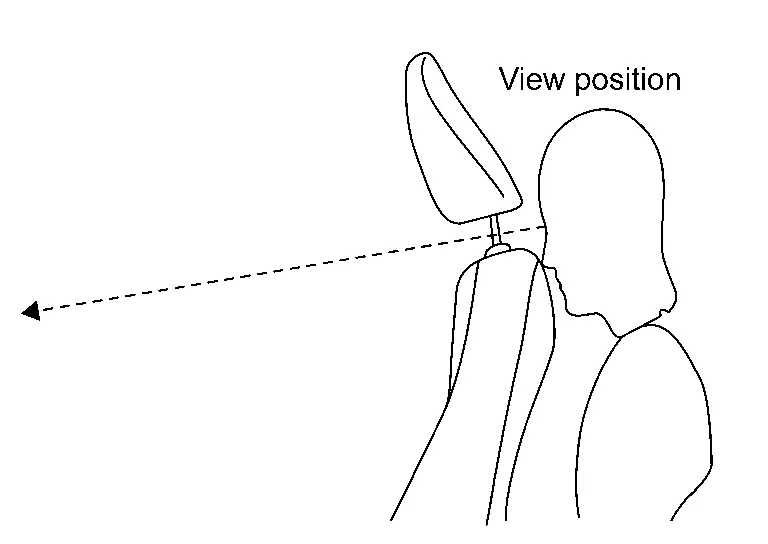

Confirm from the between seatback and headrest whether the center position of the displayed guideline is coincident with the center position of the target sheet.

NOTE:

NOTE:

If there is a gap between the target sheet and the guideline, move the target board so that the center of the target seat coincides with the center of the guideline.

>>

GO TO 6.

PERFORM DISTORTION CALIBRATION

CONSULT

CONSULT

-

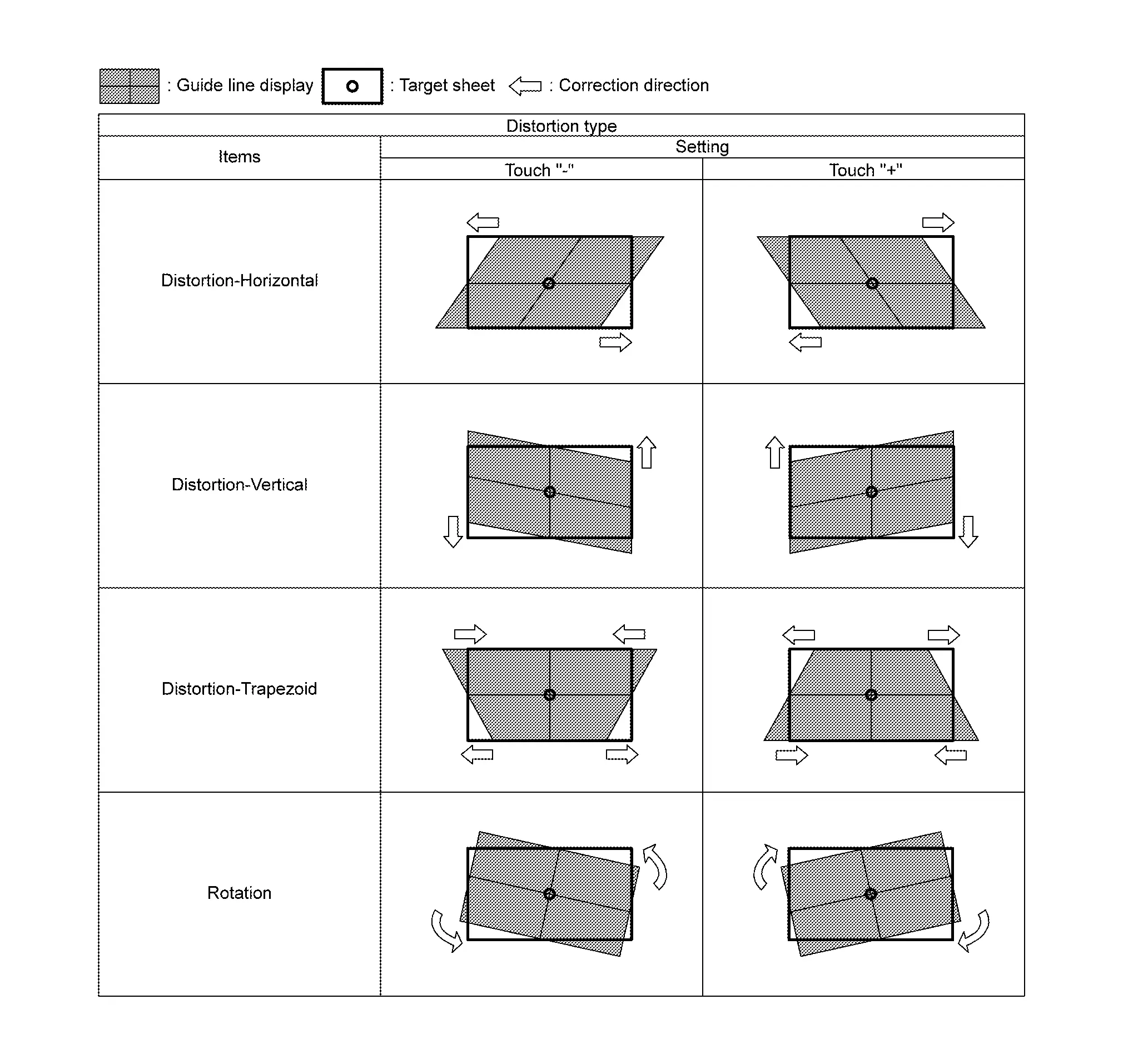

Check the distortion of the guideline from the between seatback and headrest.

-

If the guideline display is distorted, touch "+" or "-" of the item corresponding to the distortion type to be corrected according to following table, and calibrate to match the target sheet.

-

Select "Save" and save the setting when calibration is completed.

NOTE:

NOTE:

Select "Reset" to cancel the change.

>>

Work End.

Other materials:

Dtc/circuit Diagnosis. Back Door Opener Actuator

Component Function Check

CHECK FUNCTION

CONSULT

Ignition switch ON.

Select ãTrunk/back doorã in ãActive testã mode of "BCM".

Check that the function operates normally according to the following conditions.

Monitor item Status

Trunk/back door

On

Back door

OPEN ...

Diagnosis System (driver Monitor Camera Control Unit)

CONSULT Function (Driver Monitor Camera)

APPLICATION ITEMSCONSULT performs the following functions via CAN communication using driver monitor camera control unit. Diagnosis mode Description

Self Diagnostic Result

Retrieve DTC from ECU and display diagnostic items

Data Monitor

Monitor ...

B24c6-12 Blower Motor Control

DTC Description

DTC DETECTION LOGIC DTC No.

CONSULT screen terms

(Trouble diagnosis content) DTC detection condition

B24C6ã12

BLOWER MOTOR CONTROL

(Blower motor control)

[CIRCUIT SHORT TO GROUND]

Diagnosis condition

When ignition switch is ON

Signal (Terminal)

Blower ...