Nissan Rogue (T33) 2021-Present Service Manual: Transmission (tcm)

P0604-00 Control Module Ram

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0604 | 00 |

Control module RAM [Internal Control Module Read Access Memory (RAM) Error] |

Diagnosis condition | When the ignition switch is ON |

| Signal | â | |||

| Threshold | TCM RAM area sum parity check detects malfunction in RAM. | |||

| Diagnosis delay time | â | |||

POSSIBLE CAUSE

TCM (RAM)

FAIL-SAFE

-

Selector shock is large

-

Start is slow

-

Acceleration is slow

-

Lock-up is not performed

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC CONFIRMATION PROCEDURE

-

Ignition switch ON.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

REPLACE TCM

Replace TCM. Refer to Removal and Installation.

>>

WORK END

P0605-00 Control Module Rom

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0605 | 00 |

Control module ROM [Internal Control Module Read Access Memory (ROM) Error] |

Diagnosis condition | When the ignition switch is ON |

| Signal | â | |||

| Threshold | TCM ROM area sum parity check detects malfunction in ROM. | |||

| Diagnosis delay time | â | |||

POSSIBLE CAUSE

TCM (ROM)

FAIL-SAFE

-

Selector shock is large

-

Start is slow

-

Acceleration is slow

-

Lock-up is not performed

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC CONFIRMATION PROCEDURE

-

Ignition switch ON.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

REPLACE TCM

Replace TCM. Refer to Removal and Installation.

>>

WORK END

P0606-00 Control Module

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0606 | 00 |

Control module processor (Control Module Processor) |

Diagnosis condition | When the ignition switch is ON |

| Signal | â | |||

| Threshold |

One of the following error information in micro-controller is satisfied. a) CPU diagnosis error. b) Memory access diagnosis error. c) Clock diagnosis error. d) Program flow diagnosis error |

|||

| Diagnosis delay time | â | |||

POSSIBLE CAUSE

TCM

FAIL-SAFE

-

Selector shock is large

-

Start is slow

-

Acceleration is slow

-

Lock-up is not performed

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC CONFIRMATION PROCEDURE

-

Ignition switch ON.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

REPLACE TCM

Replace TCM. Refer to Removal and Installation.

>>

WORK END

P060a-00 Control Module

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P060A | 00 |

Internal control module monitoring processor (Internal Control Module Monitoring Processor Performance) |

Diagnosis condition | When the ignition switch is ON |

| Signal | â | |||

| Threshold |

One of the following error information in micro-controller is satisfied. a) CPU diagnosis error. b) Analog-to-digital converter functional diagnosis error. c) Watchdog timar diagnosis error. d) Sub micro-controller diagnosis error. e) Communication diagnosis error between micro-controller and sub micro-controller. f) Blocking diagnosis error of power supply for solenoid. g) Blocking diagnosis error of CAN communication. |

|||

| Diagnosis delay time | â | |||

POSSIBLE CAUSE

TCM

FAIL-SAFE

-

Selector shock is large

-

Start is slow

-

Acceleration is slow

-

Lock-up is not performed

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC CONFIRMATION PROCEDURE

-

Ignition switch ON.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

REPLACE TCM

Replace TCM. Refer to Removal and Installation.

>>

WORK END

P062f-00 Eeprom

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P062F | 00 |

Control module EEPROM (Internal Control Module EEPROM Error) |

Diagnosis condition | When turning ON the ignition switch. |

| Signal | â | |||

| Threshold | Flash ROM error is detected | |||

| Diagnosis delay time | Immediately | |||

POSSIBLE CAUSE

TCM (Flash ROM)

FAIL-SAFE

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC CONFIRMATION PROCEDURE

-

Start the engine.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

REPLACE TCM

Replace TCM. Refer to Removal and Installation.

YES>>

WORK END

P06b1-00 Sensor Power Supply a

DTC Description

DTC DETECTION LOGIC

| DTC | CONSULT screen terms (Trouble diagnosis content) | DTC detection condition | ||

|---|---|---|---|---|

| P06B1 | 00 |

Sensor power supply A (Sensor Power Supply "A" Circuit Low) |

Diagnosis condition | When the ignition switch is ON |

| Signal (terminal) | â | |||

| Threshold (Assessment criteria) |

When a detection signal of DTC P06B1-00 is transmitted from the electric shift system.

For the detection condition of DTC P06B1-00, refer to DTC Description. |

|||

| Diagnosis delay time | â | |||

POSSIBLE CAUSE

-

Harness or connectors (Electric shift sensor circuits are open or shorted.)

-

Electric shift sensor

-

Electric shift control module

FAIL-SAFE

Determination time of the shift selector position becomes long (1 second or more)

DTC CONFIRMATION PROCEDURE

Refer to DTC P06B1-00 description of electric shift system. Refer to DTC Description.

Diagnosis Procedure

Refer to DTC P06B1-00 diagnosis procedure of electric shift system. Refer to DTC Diagnosis Procedure.

P0705-00 Transmission Range Sensor a

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0705 | 00 |

Transmission range sensor A [Transmission Range Sensor "A" Circuit (PRNDL Input)] |

Diagnosis condition | Power supply voltage âĨ 10 V |

| Signal | Transmission range switch signal | |||

| Threshold | When there is undefined range pattern input | |||

| Diagnosis delay time | 2 seconds | |||

POSSIBLE CAUSE

-

Harness or connector

-

Transmission range switch

-

TCM

FAIL-SAFE

-

Shift position indicator on combination meter is not displayed

-

Powertrain becomes neutral

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

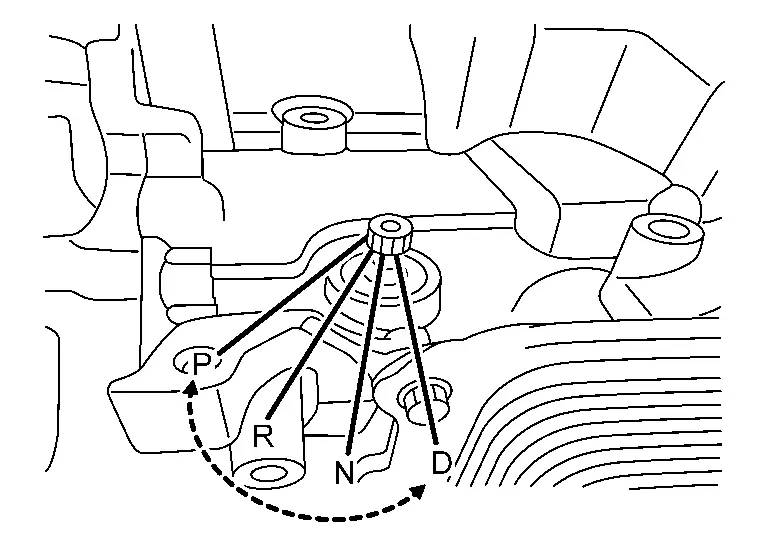

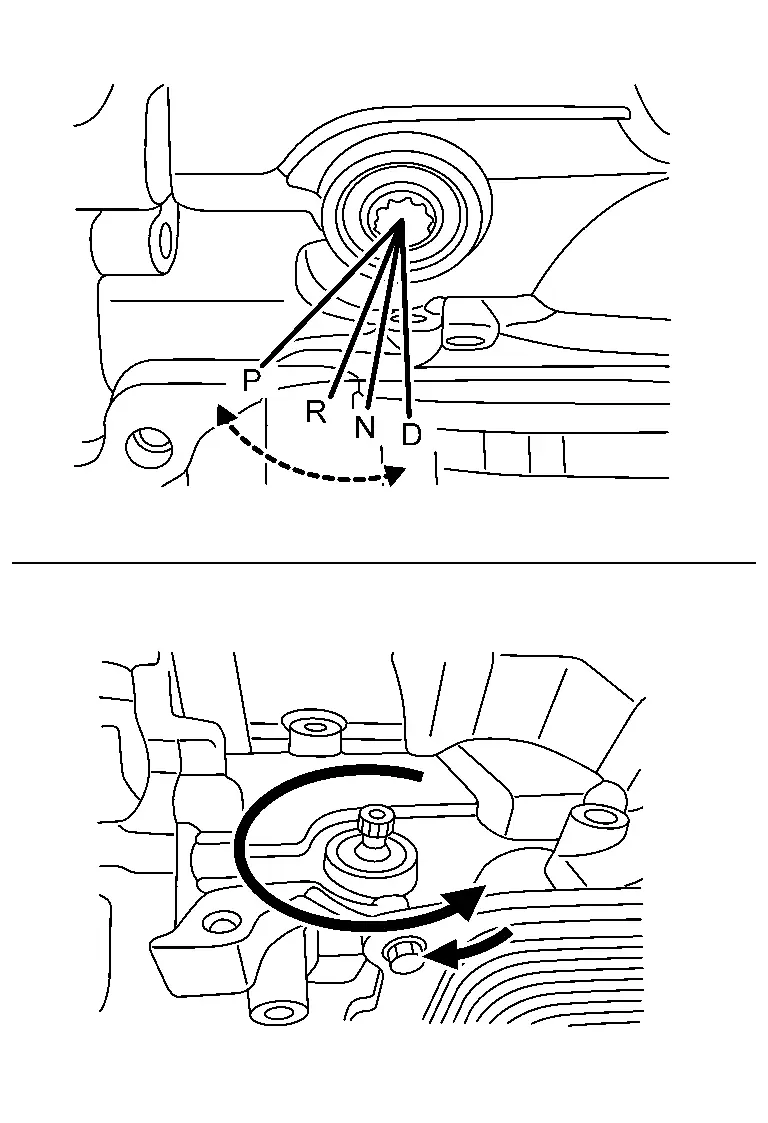

PERFORM DTC CONFIRMATION PROCEDURE

-

Start the engine.

-

Depress the brake pedal.

-

Shift the selector lever to "R" position and wait for 5 seconds or more.

-

Shift the selector lever to "N" position and wait for 5 seconds or more.

-

Shift the selector lever to "D/M" position and wait for 5 seconds or more.

-

Press P position switch and wait for 5 seconds or more.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK TRANSMISSION RANGE SWITCH CIRCUIT

Check transmission range switch circuit. Refer to Diagnosis Procedure.

>>

INSPECTION END

P0706-00 Transmission Range Sensor a

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0706 | 00 |

Transmission range sensor A (Transmission Range Sensor "A" Circuit Range/Performance) |

Diagnosis condition | Power supply voltage âĨ 10 V |

| Signal | Transmission range switch signal | |||

| Threshold | When there is range pattern input of intermediate range | |||

| Diagnosis delay time | 2 seconds | |||

POSSIBLE CAUSE

-

Harness or connector

-

Transmission range switch

-

TCM

FAIL-SAFE

-

Shift position indicator on combination meter is not displayed

-

Powertrain becomes neutral

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC CONFIRMATION PROCEDURE

-

Start the engine.

-

Depress the brake pedal.

-

Shift the selector lever to "R" position and wait for 5 seconds or more.

-

Shift the selector lever to "N" position and wait for 5 seconds or more.

-

Shift the selector lever to "D/M" position and wait for 5 seconds or more.

-

Press P position switch and wait for 5 seconds or more.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK TRANSMISSION RANGE SWITCH CIRCUIT

Check transmission range switch circuit. Refer to Diagnosis Procedure.

>>

INSPECTION END

P0711-00 Transmission Fluid Temperature Sensor a

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | |||

| P0711 | 00 |

Transmission fluid temperature sensor A (Transmission Fluid Temperature Sensor A Circuit Range/Performance) |

1 | Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Power supply voltage: More than 11 V b) CAN communication is normal d) Accelerator pedal position: 3 deg or more e) Nissan Ariya Vehicle speed: 10 km/h (7 MPH) or more f) Shift position: D position |

| Signal | CVT fluid temperature sensor signal | ||||

| Threshold | CVT fluid temperature does not rise to 10°C (50°F) after driving for a certain period of time with the TCM-received fluid temperature sensor value between â 40°C (â40°F) and 9°C (48.2°F). | ||||

| Diagnosis delay time | â | ||||

| 2 | Diagnosis condition |

Diagnosis is permitted when all of the following conditions satisfied: a) Power supply voltage: 11 V or more b) The difference between CVT fluid temperature and engine coolant temperature is 44°C (111°F) or more, or â27°C (â16°F) or less. c) Engine speed: 305 rpm or more |

|||

| Signal | CVT fluid temperature sensor signal | ||||

| Threshold |

DTC is detected when all of the following conditions are satisfied: a) ECM is normal. b) Diagnosis condition is satisfied. |

||||

| Diagnosis delay time | 300 seconds | ||||

POSSIBLE CAUSE

-

Harness or connector

-

CVT fluid temperature sensor

-

TCM

FAIL-SAFE

-

Engine coolant temperature when engine start: Temp. âĨ 10°C (50°F)

-

Start is slow

-

Acceleration is slow

-

-

Engine coolant temperature when engine start: â35°C (â31°F) âĪ Temp. < 10°C (50°F)

-

Selector shock is large

-

Start is slow

-

Acceleration is slow

-

-

Engine coolant temperature when engine start: Temp. <â35°C (â31°F)

-

Selector shock is large

-

Start is slow

-

Acceleration is slow

-

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch is OFF and wait for at least 10 seconds, then perform the next test.

>>

GO TO 2.

INSPECTION START

Is it necessary to erase permanent DTC?

YES>>GO TO 3.

NO>>GO TO 7.

CHECK DTC (ECM AND TCM)

Check the DTC.

Is any DTC other than âP0711â00â detected?

YES>>Check DTC detected item. Refer to DTC Index (ECM), DTC Index (TCM).

NO>>GO TO 4.

PERFORM DTC CONFIRMATION PROCEDURE (PART 1)

TESTING CONDITION:

-

While performing the following procedure, never add fuel.

-

Before performing the following procedure, check that fuel level is between 1/4 and 4/4.

-

Before performing the following procedure, confirm that battery voltage is 11 V or more at idle.

With CONSULT

With CONSULT

-

Move the Nissan Ariya vehicle to a cool place.

NOTE:

NOTE:

Cool the vehicle in an environment of ambient air temperature between â10°C (14°F) and 35°C (95°F).

-

Ignition switch OFF and leave the Nissan Ariya vehicle for 12 hours.

CAUTION:

Never the ignition switch is ON during this procedure.

NOTE:

NOTE:

The Nissan Ariya vehicle must be cooled with the food open.

-

Ignition switch ON.

CAUTION:

Never start the engine.

-

Select âData Monitorâ in âTRANSMISSIONâ.

-

Select âTransmission fluid temperatureâ.

-

Record CVT fluid temperature.

-

Start engine and let it idle for 5 minutes or more.

CAUTION:

Never the ignition switch is OFF during idling.

-

Check 1st trip DTC.

With GST

With GST

-

Move the Nissan Ariya vehicle to a cool place.

NOTE:

NOTE:

Cool the vehicle in an environment of ambient air temperature between â10°C (14°F) and 35°C (95°F).

-

Ignition switch OFF and leave the Nissan Ariya vehicle for 12 hours.

CAUTION:

Never the ignition switch is ON during this procedure.

NOTE:

NOTE:

The Nissan Ariya vehicle must be cooled with the food open.

-

Start engine and let it idle for 5 minutes or more.

CAUTION:

Never the ignition switch is OFF during idling.

-

Check 1st trip DTC.

Is âP0711â00â detected?

YES>>Go to Diagnosis Procedure.

NO-1>>With CONSULT: GO TO 5.

NO-2>>With GST: GO TO 6.

CHECK CVT FLUID TEMPERATURE

With CONSULT

With CONSULT

-

Select âData Monitorâ in âTRANSMISSIONâ.

-

Select âTransmission fluid temperatureâ.

Is the value of âTransmission fluid temperatureâ 10°C (50°F) or more?

YES>>INSPECTION END

NO>>GO TO 6.

PERFORM DTC CONFIRMATION PROCEDURE (PART 2)

With CONSULT

With CONSULT

-

Drive the Nissan Ariya vehicle for the total minutes specified in the Driving time column below with the following conditions satisfied.

Shift position : âDâ position Accelerator pedal position : 1.0/8 or more Nissan Ariya Vehicle speed : 10 km/h (7 MPH) or more CVT fluid temperature before engine start Driving time â40°C (â40°F) ââ31°C (â23.8°F) 20 minutes or more â30°C (â22°F) ââ21°C (â5.8°F) 18 minutes or more â20°C (â4°F) ââ11°C (â12.2°F) 14 minutes or more â10°C (14°F) ââ1°C (30.2°F) 10 minutes or more 0°C (32°F) â 9°C (48.2°F) 7 minutes or more -

Stop the Nissan Ariya vehicle.

-

Check the first trip DTC.

With GST

With GST

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 20 minutes or more.

Shift position : âDâ position Accelerator pedal position : 1.0/8 or more Nissan Ariya Vehicle speed : 10 km/h (7 MPH) or more -

Stop the vehicle.

-

Check the first trip DTC.

Is âP0711â00â detected?

YES>>Go to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Ignition switch OFF and cool the engine.

-

Ignition switch ON.

CAUTION:

Never start the engine.

-

Select âData Monitorâ in âTRANSMISSIONâ.

-

Select âTransmission fluid temperatureâ.

-

Record CVT fluid temperature.

-

Start the engine and wait for at least 2 minutes.

-

Drive the Nissan Ariya vehicle for the total minutes specified in the Driving time column below with the following conditions satisfied.

Shift position : âDâ position Accelerator pedal position : 1.0/8 or more Nissan Ariya Vehicle speed : 10 km/h (7 MPH) or more CVT fluid temperature before engine start Driving time â40°C (â40°F) ââ31°C (â23.8°F) 20 minutes or more â30°C (â22°F) ââ21°C (â5.8°F) 18 minutes or more â20°C (â4°F) ââ11°C (â12.2°F) 14 minutes or more â10°C (14°F) ââ1°C (30.2°F) 10 minutes or more 0°C (32°F) â 9°C (48.2°F) 7 minutes or more Other than the above â (Go to â8.CHECK CVT FLUID TEMPERATURE SENSORâ) -

Stop the Nissan Ariya vehicle.

-

Check the first trip DTC.

With GST

With GST

-

Ignition switch OFF and cool the engine.

-

Start the engine and wait for at least 2 minutes.

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 20 minutes or more.

Shift position : âDâ position Accelerator pedal position : 1.0/8 or more Nissan Ariya Vehicle speed : 10 km/h (7 MPH) or more -

Stop the vehicle.

CAUTION:

Never the ignition switch is OFF

-

Check the first trip DTC.

Is âP0711â00â detected?

YES>>Go to Diagnosis Procedure.

NO>>GO TO 8.

CHECK CVT FLUID TEMPERATURE SENSOR

-

Ignition switch is OFF.

-

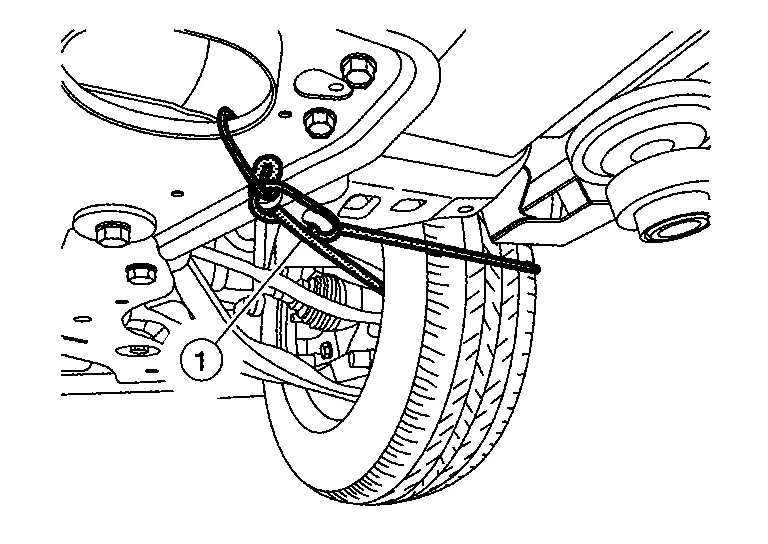

Remove TCM. Refer to Removal and Installation

-

Check resistance between TCM harness connector terminals.

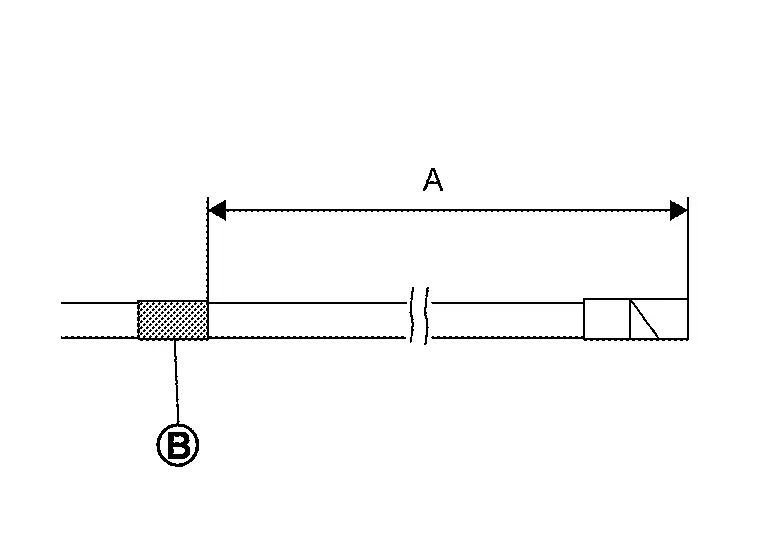

TCM Condition Resistance

(Approx.)Connector Terminal F115 5 â 12 CVT fluid temperature: 20°C (68°F) 6.5 kâĶ CVT fluid temperature: 50°C (122°F) 2.2 kâĶ

Is the inspection result normal?

YES-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

YES-2>>Confirmation after repair: INSPECTION END

NO>>There is a malfunction of CVT fluid temperature sensor. Replace terminal cord assembly. Refer to Removal and Installation.

Diagnosis Procedure

CHECK CVT FLUID TEMPERATURE SENSOR CIRCUIT

Check CVT fluid temperature sensor circuit. Refer to Diagnosis Procedure.

>>

INSPECTION END

P0712-00 Transmission Fluid Temperature Sensor a

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0712 | 00 |

Transmission fluid temperature sensor A (Transmission Fluid Temperature Sensor "A" Circuit Low) |

Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Power supply voltage âĨ 10 V b) Nissan Ariya Vehicle speed âĨ 0 km/h (0 MPH) |

| Signal | CVT fluid temperature signal | |||

| Threshold | CVT fluid temperature sensor detecting voltage âĪ 0.15 V [CVT fluid temperature âĨ 180 °C (356 °F)] | |||

| Diagnosis delay time | 5 seconds | |||

POSSIBLE CAUSE

-

Harness or connector

-

CVT fluid temperature sensor

-

TCM

FAIL-SAFE

-

Engine coolant temperature when engine start: Temp. âĨ 10°C (50°F)

-

Start is slow

-

Acceleration is slow

-

-

Engine coolant temperature when engine start: â35°C (â31°F) âĪ Temp. < 10°C (50°F)

-

Selector shock is large

-

Start is slow

-

Acceleration is slow

-

-

Engine coolant temperature when engine start: Temp. <â35°C (â31°F)

-

Selector shock is large

-

Start is slow

-

Acceleration is slow

-

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following condition for 10 seconds or more.

Nissan Ariya Vehicle speed : 10 km/h (6 MPH) or more CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK CVT FLUID TEMPERATURE SENSOR CIRCUIT

Check CVT fluid temperature sensor circuit. Refer to Diagnosis Procedure.

>>

INSPECTION END

P0713-00 Transmission Fluid Temperature Sensor a

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0713 | 00 |

Transmission fluid temperature sensor A (Transmission Fluid Temperature Sensor "A" Circuit High) |

Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Power supply voltage âĨ 10 V b) Nissan Ariya Vehicle speed âĨ 10 km/h (6 MPH) |

| Signal | CVT fluid temperature signal | |||

| Threshold | CVT fluid temperature sensor detecting voltage âĨ 2.48 V [CVT fluid temperature âĪ -40 °C (-40 °F)] | |||

| Diagnosis delay time | 5 seconds | |||

POSSIBLE CAUSE

-

Harness or connector

-

CVT fluid temperature sensor

-

TCM

FAIL-SAFE

-

Engine coolant temperature when engine start: Temp. âĨ 10°C (50°F)

-

Start is slow

-

Acceleration is slow

-

-

Engine coolant temperature when engine start: â35°C (â31°F) âĪ Temp. < 10°C (50°F)

-

Selector shock is large

-

Start is slow

-

Acceleration is slow

-

-

Engine coolant temperature when engine start: Temp. <â35°C (â31°F)

-

Selector shock is large

-

Start is slow

-

Acceleration is slow

-

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following condition for 10 seconds or more.

Nissan Ariya Vehicle speed : 10 km/h (6 MPH) or more CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK CVT FLUID TEMPERATURE SENSOR CIRCUIT

Check CVT fluid temperature sensor circuit. Refer to Diagnosis Procedure.

>>

INSPECTION END

P0715-00 Input Speed Sensor a

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0715 | 00 |

Input/Turbine shaft speed sensor A (Input/Turbine Shaft Speed Sensor "A" Circuit) |

Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Ignition voltage âĨ 9.01 V b) Battery voltage âĨ 9.01 V |

| Signal | Input speed sensor signal | |||

| Threshold |

DTC is detected when one of the following conditions a) to b) are satisfied: Input speed sensor signal voltage: a) 4.311 V âĪ sensor signal < 4.6 V b) 0.108 V âĪ sensor signal < 0.719 V |

|||

| Diagnosis delay time | 0.2 seconds | |||

POSSIBLE CAUSE

-

Harness or connector

-

Input speed sensor

-

TCM

FAIL-SAFE

-

Lock-up is not performed

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 10 seconds or more.

Shift position : "D" position Nissan Ariya Vehicle speed : 40 km/h (25 MPH) or more CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK INPUT SPEED SENSOR CIRCUIT

Check input speed sensor circuit. Refer to Diagnosis Procedure.

>>

INSPECTION END

P0716-00 Input Speed Sensor a

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0716 | 00 |

Input/Turbine shaft speed sensor A (Input/Turbine Shaft Speed Sensor "A" Circuit Range/Performance) |

Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Ignition voltage âĨ 9.01 V b) Battery voltage âĨ 9.01 V c) Range : D d) Primary and secondary pulley speed sensors: Normal e) Primary pulley speed > 300 rpm f) Secondary pulley speed > 860 rpm g) Engine speed ⧠450 rpm |

| Signal | Input speed sensor signal | |||

| Threshold |

DTC is detected when one of the following conditions a) to b) are satisfied: a) Current pulse frequency / Last pulse frequency âĨ2 b) Current pulse frequency / Last pulse frequency âĪ1/2 |

|||

| Diagnosis delay time | â | |||

POSSIBLE CAUSE

-

Harness or connector

-

Input speed sensor (source reading input speed sensor value)

-

TCM

FAIL-SAFE

-

Lock-up is not performed

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 10 seconds or more.

Shift position : "D" position Nissan Ariya Vehicle speed : 40 km/h (25 MPH) or more CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK INPUT SPEED SENSOR CIRCUIT

Check input speed sensor circuit. Refer to Diagnosis Procedure.

>>

INSPECTION END

P0717-00 Input Speed Sensor a

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | |||

| P0717 | 00 |

Input/Turbine shaft speed sensor A (Input/Turbine Shaft Speed Sensor "A" Circuit No Signal) |

1 | Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Time passed after changing the range > 2 sec b) Power supply voltage âĨ 10 V c) Input speed âĨ 1000 rpm d) Primary pulley speed âĨ 1000 rpm e) Except N (P) range |

| Signal | Input speed sensor signal | ||||

| Threshold |

DTC is detected when all of the following conditions are satisfied: a) Input speed < 150 rpm b) Primary pulley speed âĨ 500 rpm |

||||

| Diagnosis delay time | 5 seconds | ||||

| 2 | Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied:

|

|||

| Signal | Input speed sensor signal | ||||

| Threshold |

DTC is detected when all of the following conditions are satisfied: a) Last input speed âĨ 1000 rpm b) Current input speed âĪ 240 rpm |

||||

| Diagnosis delay time | 0.5 seconds | ||||

POSSIBLE CAUSE

-

Harness or connector (Input speed sensor circuit is open or shorted)

-

Input speed sensor

-

TCM

-

Control valve

-

Solenoid

FAIL-SAFE

-

Lock-up is not performed

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 10 seconds or more.

Shift position : "D" position Nissan Ariya Vehicle speed : 40 km/h (25 MPH) or more CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK DTC PRIORITY

When DTC P0717-00 is displayed together with any following DTC, diagnose first the other DTC.

-

P0746-00, P0747-00, P0776-00, P0777-00, P0796-00, P0797-00

Is applicable DTC detected?

YES>>Perform diagnosis of applicable. DTC Index.

NO>>GO TO 2.

CHECK INPUT SPEED SENSOR CIRCUIT

Check input speed sensor circuit. Refer to Diagnosis Procedure.

>>

INSPECTION END

P0718-00 Input Speed Sensor a

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0718 | 00 |

Input/Turbine shaft speed sensor A (Input/Turbine Shaft Speed Sensor "A" Circuit Intermittent) |

Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Ignition voltage âĨ 9.01 V b) Battery voltage âĨ 9.01 V |

| Signal | Input speed sensor signal | |||

| Threshold | Input speed ïž 7300 rpm | |||

| Diagnosis delay time | 2 seconds | |||

POSSIBLE CAUSE

-

Harness or connector

-

Input speed sensor

-

TCM

FAIL-SAFE

Lock-up is not performed

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 10 seconds or more.

Shift position : "D" position Nissan Ariya Vehicle speed : 80 km/h (49 MPH) CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK INPUT SPEED SENSOR CIRCUIT

Check input speed sensor circuit. Refer to Diagnosis Procedure.

>>

INSPECTION END

P072a-00 Stuck in Neutral

DTC Description

DTC DETECTION LOGIC

| DTC | CONSULT screen terms (Trouble diagnosis content) | DTC detection condition | ||

|---|---|---|---|---|

| P072A | 00 |

Stuck in neutral (Stuck in Neutral) |

Diagnosis condition | When the ignition switch is ON |

| Signal (terminal) | â | |||

| Threshold (Assessment criteria) |

When a detection signal of DTC P072A-00 is transmitted from the electric shift system.

For the detection condition of DTC P072A-00, refer to DTC Description. |

|||

| Diagnosis delay time | â | |||

POSSIBLE CAUSE

Transaxle assembly (Sticking of manual shaft)

FAIL-SAFE

Shifting operation is prohibited

DTC CONFIRMATION PROCEDURE

Refer to DTC P072A-00 description of electric shift system. Refer to DTC Description.

Diagnosis Procedure

Refer to DTC P072A-00 diagnosis procedure of electric shift system. Refer to DTC Diagnosis Procedure.

P0740-00 Torque Converter

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0740 | 00 |

Torque converter clutch (Torque Converter Clutch Circuit/Open) |

Diagnosis condition | Power supply voltage âĨ 10 V |

| Signal | â | |||

| Threshold | Solenoid valve drive circuit is diagnosed as open | |||

| Diagnosis delay time | 0.2 seconds | |||

POSSIBLE CAUSE

-

Harness or connector

-

Torque converter clutch solenoid valve

-

TCM

FAIL-SAFE

-

Start is slow

-

Acceleration is slow

-

Lock-up is not performed

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 10 seconds or more.

Shift position : "D" position CVT fluid temperature : 20 °C (68 °F) or more Nissan Ariya Vehicle speed : 40 km/h (25 MPH) or more CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK TORQUE CONVERTER CLUTCH SOLENOID VALVE CIRCUIT

Check torque converter clutch solenoid valve circuit. Refer to Diagnosis Procedure.

>>

INSPECTION END

P0741-00 Torque Converter

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0741 | 00 |

Torque converter clutch (Torque Converter Clutch Circuit Performance/Stuck Off) |

Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Lock up clutch target pressure (pressure difference) > 0.2 MPa b) Lock up range (except for lock up slip) c) Power supply voltage âĨ 10 V |

| Signal | â | |||

| Threshold | Lock up clutch slip speed âĨ 40 + Nissan Ariya Vehicle speed / 2 km/h | |||

| Diagnosis delay time | 10 seconds | |||

POSSIBLE CAUSE

-

Harness or connector

-

Torque converter clutch solenoid valve

-

Control valve

-

Torque converter

-

TCM

FAIL-SAFE

-

Start is slow

-

Acceleration is slow

-

Lock-up is not performed

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 20 seconds or more.

Shift position : "D" position Accelerator pedal position : 0.5/8 or more CVT fluid temperature : 20 °C (68 °F) or more Nissan Ariya Vehicle speed : 40 km/h (25 MPH) or more CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

REPLACE TRANSAXLE ASSEMBLY

Replace transaxle assembly. Refer to Removal and Installation.

>>

WORK END

P0742-00 Torque Converter

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0742 | 00 |

Torque converter clutch (Torque Converter Clutch Circuit Stuck On) |

Diagnosis condition |

Diagnosis is permitted when all of the following conditions to are satisfied: a) Shift position is not D and M range b) Acceleration pedal opening angle âĨ 10 deg c) 0rpm < secondary pulley speed < 2300 rpm d) Engine speed âĨ 450 rpm e) Period satisfying the following e-1) is no longer than 0.02 sec. e-1) Speed difference caused by clutch (Input speed - Primary pulley speed âĨ 50 rpm f) The following f-1) is satisfied for 5 sec or more. f-1) Lock up instruction pressure âĪ -0.1 MPa g) Power supply voltage âĨ 10 V h) Engine torque âĨ Approximately 50 N·m |

| Signal | â | |||

| Threshold | Absolute value of speed difference caused by T/C âĪ 40 rpm | |||

| Diagnosis delay time | 5 seconds | |||

POSSIBLE CAUSE

-

Harness or connector

-

Torque converter clutch solenoid valve

-

Control valve assembly

-

Torque converter

-

TCM

FAIL-SAFE

-

Start is slow

-

Acceleration is slow

-

Engine stops when shift to âDâ position during stopping the Nissan Ariya vehicle.

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 10 seconds or more.

Shift position : "D" position Accelerator pedal opening : 10 deg or more Nissan Ariya Vehicle speed : 1 - 15 km/h (0.6 - 9 MPH) Brake pedal : Depress* *: Keep depressing the brake pedal moderately not to accelrate the Nissan Ariya vehicle.

CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

REPLACE TRANSAXLE ASSEMBLY

Replace transaxle assembly. Refer to Removal and Installation.

>>

WORK END

P0746-00 Pressure Control Solenoid a

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0746 | 00 |

Pressure control solenoid A (Pressure Control Solenoid "A" Performance/Stuck Off) |

Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Ignition voltage âĨ 9.01 V b) Battery voltage âĨ 9.01 V c) -20 °C (-4 °F) âĪ CVT fluid temperature d) Lockup pattern = Lock-up ON or Lock-up OFF e) Engine speed > 450 rpm |

| Signal | â | |||

| Threshold |

When the following conditions a) and b) are satisfied for the specified period [5 sec] continuously. Keep the same conditions for specified period again after interval. a) Line pressure sensor pressure < Balanced oil quantity lower limit pressure - Variation b) Line pressure sensor pressure < Line instruction pressure - Variation [Interval]

|

|||

| Diagnosis delay time | 5 seconds à 2 count | |||

POSSIBLE CAUSE

-

Harness or connector

-

Line pressure solenoid valve

-

Control valve assembly

-

TCM

FAIL-SAFE

-

Lock-up is not performed

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 20 seconds or more.

Shift position : "D" position CVT fluid temperature : 25 °C (77 °F) - 120 °C (248 °F) Nissan Ariya Vehicle speed : 40 km/h (25 MPH) or more CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Repeat step 2 to 3.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

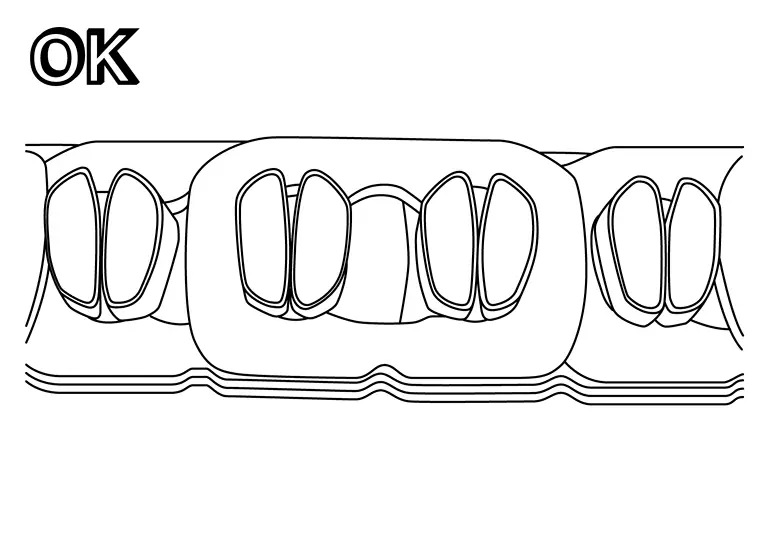

INSPECT CVT CHAIN BELT

Inspect the CVT chain belt. Refer to Component Inspection.

Is CVT chain belt OK?

YES>>GO TO 2.

NO>>GO TO 4.

CHECK LINE PRESSURE SOLENOID VALVE CIRCUIT (1)

-

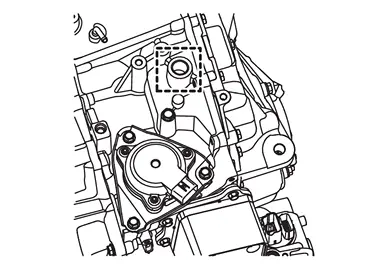

Remove TCM. Refer to Removal and Installation.

-

Remove oil pan. Refer to Removal and Installation.

-

Disconnect control valve harness connector. Refer to Removal and Installation.

-

Check the resistance between TCM harness connector and control valve harness connector.

Circuit TCM Control valve Resistance Connector Terminal Connector Terminal Line pressure solenoid valve F116 18 F118 8 1 ÎĐ or less -

Check that terminal assembly B is not damaged.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Replace terminal assembly A and terminal assembly B as a set. Refer to Removal and Installation.

REPLACE CONTROL VALVE

Replace control valve assembly. Refer to Removal and Installation.

>>

GO TO 7.

CHECK LINE PRESSURE SOLENOID VALVE CIRCUIT (2)

-

Remove TCM. Refer to Removal and Installation.

-

Remove oil pan. Refer to Removal and Installation.

-

Disconnect control valve harness connector. Refer to Removal and Installation.

-

Check the resistance between TCM harness connector and control valve harness connector.

Circuit TCM Control valve Resistance Connector Terminal Connector Terminal Line pressure solenoid valve F116 18 F118 8 1 ÎĐ or less -

Check that terminal assembly B is not damaged.

Is the inspection result normal?

YES>>GO TO 5.

NO>>GO TO 6.

REPLACE BELT AND PULLEY ASSEMBLY, AND CONTROL VALVE

Replace belt and pulley assembly and control valve. Refer to Disassembly & Assembly.

>>

GO TO 7.

REPLACE BELT AND PULLEY ASSEMBLY, CONTROL VALVE, AND TERMINAL ASSEMBLY B

Replace belt and pulley assembly, control valve, and terminal assembly B. Refer to Disassembly & Assembly.

>>

GO TO 7.

CHECK DTC CONFIRMATION PROCEDURE

Perform DTC confirmation procedure. Refer to DTC Description.

Is DTC detected?

YES>>Replace TCM. Refer to Removal and Installation.

NO>>INSPECTION END

P0747-00 Pressure Control Solenoid a

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0747 | 00 |

Pressure control solenoid A (Pressure Control Solenoid "A" Stuck On) |

Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Ignition voltage âĨ 9.01 V b) Battery voltage âĨ 9.01 V c) -20 °C (-4 °F) âĪ CVT fluid temperature d) Lockup pattern = Lock-up ON or Lockup OFF e) Engine speed > 450 rpm |

| Signal | â | |||

| Threshold |

When the following condition is satisfied for the specified period [5sec] continuously. Keep the same conditions for specified period again after interval. a) Line pressure sensor pressure > Line instruction pressure + Variation [Interval]

|

|||

| Diagnosis delay time | 5 seconds à 2 count | |||

POSSIBLE CAUSE

-

Harness or connector

-

Line pressure solenoid valve

-

Control valve assembly

-

TCM

FAIL-SAFE

-

Lock-up is not performed

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 20 seconds or more.

Shift position : "D" position CVT fluid temperature : 25 °C (77 °F) - 120 °C (248 °F) Nissan Ariya Vehicle speed : 40 km/h (25 MPH) or more CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Repeat step 2 to 3.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK LINE PRESSURE SOLENOID VALVE CIRCUIT

-

Ignition switch OFF.

-

Remove TCM. Refer to Removal and Installation.

-

Remove oil pan. Refer to Removal and Installation.

-

Disconnect control valve harness connector. Refer to Removal and Installation.

-

Check the resistance between TCM harness connector and control valve harness connector.

Circuit TCM Control valve Resistance Connector Terminal Connector Terminal Line pressure solenoid valve F116 18 F118 8 1 ÎĐ or less -

Check that terminal assembly B is not damaged.

Is the inspection result normal?

YES>>GO TO 2.

NO>>Replace terminal assembly A and terminal assembly B as a set. Refer to Removal and Installation.

REPLACE CONTROL VALVE

Replace control valve assembly. Refer to Removal and Installation.

>>

WORK END

P0776-00 Pressure Control Solenoid B

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | |||

| P0776 | 00 |

Pressure control solenoid B (Pressure Control Solenoid "B" Performance/Stuck Off) |

1 | Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Ignition voltage âĨ 9.01 V b) Battery voltage âĨ 9.01 V c) -20 °C (-4 °F) âĪ CVT fluid temperature d) Lockup pattern = Lock-up ON or Lockup OFF e) Engine speed > 450 rpm |

| Signal | â | ||||

| Threshold |

When the following conditions a) and b) are satisfied for the specified period [5 sec] continuously. Keep the same conditions for specified period again after interval. a) Primary pulley sensor pressure < Line pressure sensor pressure - Variation b) Line pressure sensor pressure < Line instruction pressure - Variation [Interval]

|

||||

| Diagnosis delay time | 5 seconds à 2 count | ||||

| 2 | Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Engine speed: More than 750 rpm b) Shift position: Other than P/N position c) CVT fluid temperature: More than -20 °C (-4 °F) d) TCM power supply: More than 11 V e) The difference between instruction pressure of primary pressure and 10-msec-ago instruction primary pressure is 0 MPa or more f) Instruction pressure of primary pressure: 0.72 MPa or more g) Instruction pressure of primary pressure - primary pressure: More than 1.2 MPa |

|||

| Signal | â | ||||

| Threshold |

DTC is detected when all of the following conditions are satisfied and this state is maintained for 1 second:

|

||||

| Diagnosis delay time | 10 seconds | ||||

POSSIBLE CAUSE

-

Harness or connector

-

Primary pressure solenoid valve

-

Control valve assembly

-

TCM

FAIL-SAFE

-

Vehicle speed < 40 km/h (25 MPH) or Input speed < 1300 rpm

-

Selector shock is large

-

Start is slow

-

Acceleration is slow

-

Lock-up is not performed

-

-

Other then the above

-

Selector shock is large

-

Start is slow

-

Acceleration is slow

-

Stop/start system prohibited*

-

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 20 seconds or more.

Shift position : "D" position CVT fluid temperature : 25 °C (77 °F) - 120 °C (248 °F) Nissan Ariya Vehicle speed : 40 km/h (25 MPH) or more CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Repeat step 2 to 3.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

INSPECT CVT CHAIN BELT

Inspect the CVT chain belt. Refer to Component Inspection.

Is CVT chain belt OK?

YES>>GO TO 2.

NO>>GO TO 4.

CHECK PRIMARY PRESSURE SOLENOID VALVE CIRCUIT (1)

-

Ignition switch OFF.

-

Remove TCM. Refer to Removal and Installation.

-

Remove oil pan. Refer to Removal and Installation.

-

Disconnect control valve harness connector. Refer to Removal and Installation.

-

Check the resistance between TCM harness connector and control valve harness connector.

Circuit TCM Control valve Resistance Connector Terminal Connector Terminal Primary pressure solenoid valve F116 26 F118 17 1 ÎĐ or less -

Check that terminal assembly B is not damaged.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Replace terminal assembly A and terminal assembly B as a set. Refer to Removal and Installation.

REPLACE CONTROL VALVE

Replace control valve assembly. Refer to Removal and Installation.

>>

GO TO 7.

CHECK PRIMARY PRESSURE SOLENOID VALVE CIRCUIT (2)

-

Remove TCM. Refer to Removal and Installation.

-

Remove oil pan. Refer to Removal and Installation.

-

Disconnect control valve harness connector. Refer to Removal and Installation.

-

Check the resistance between TCM harness connector and control valve harness connector.

Circuit TCM Control valve Resistance Connector Terminal Connector Terminal Primary pressure solenoid valve F116 26 F118 17 1 ÎĐ or less -

Check that terminal assembly B is not damaged.

Is the inspection result normal?

YES>>GO TO 5.

NO>>GO TO 6.

REPLACE BELT AND PULLEY ASSEMBLY, AND CONTROL VALVE

Replace belt and pulley assembly and control valve. Refer to Disassembly & Assembly.

>>

GO TO 7.

REPLACE BELT AND PULLEY ASSEMBLY, CONTROL VALVE, AND TERMINAL ASSEMBLY B

Replace belt and pulley assembly, control valve, and terminal assembly B. Refer to Disassembly & Assembly.

>>

GO TO 7.

CHECK DTC CONFIRMATION PROCEDURE

Perform DTC confirmation procedure. Refer to DTC Description.

Is DTC detected?

YES>>Replace TCM. Refer to Removal and Installation.

NO>>INSPECTION END

P0777-00 Pressure Control Solenoid B

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0777 | 00 |

Pressure control solenoid B (Pressure Control Solenoid "B" Stuck On) |

Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Ignition voltage âĨ 9.01 V b) Battery voltage âĨ 9.01 V c) -20 °C (-4 °F) âĪ CVT fluid temperature d) Lockup pattern = Lock-up ON or Lockup OFF e) Engine speed > 450 rpm |

| Signal | â | |||

| Threshold |

When the following condition a) is satisfied for the specified period [5 sec] continuously. Keep the same conditions for specified period again after interval. a) Primary pulley sensor pressure > Primary pulley instruction pressure + Variation [Interval]

|

|||

| Diagnosis delay time | 5 seconds à 2 count | |||

POSSIBLE CAUSE

-

Harness or connector

-

Primary pressure solenoid valve

-

Control valve assembly

-

TCM

FAIL-SAFE

-

Selector shock is large

-

Lock-up is not performed (When Vehicle speed < 40 km/h (25MPH) or Input speed < 1300 rpm)

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 20 seconds or more.

Shift position : "D" position CVT fluid temperature : 25 °C (77 °F) - 120 °C (248 °F) Nissan Ariya Vehicle speed : 40 km/h (25 MPH) or more CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Repeat step 2 to 3.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK PRIMARY PRESSURE SOLENOID VALVE CIRCUIT

-

Ignition switch OFF.

-

Remove TCM. Refer to Removal and Installation.

-

Remove oil pan. Refer to Removal and Installation.

-

Disconnect control valve harness connector. Refer to Removal and Installation.

-

Check the resistance between TCM harness connector and control valve harness connector.

Circuit TCM Control valve Resistance Connector Terminal Connector Terminal Primary pressure solenoid valve F116 26 F118 17 1 ÎĐ or less -

Check that terminal assembly B is not damaged.

Is the inspection result normal?

YES>>GO TO 2.

NO>>Replace terminal assembly A and terminal assembly B as a set. Refer to Removal and Installation.

REPLACE CONTROL VALVE

Replace control valve assembly. Removal and Installation.

>>

WORK END

P0780-00 Shift Error

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | |||

| P0780 | 00 |

Shift error (Shift Error) |

1 | Diagnosis condition | When the ignition switch is ON |

| Signal | â | ||||

| Threshold | When the discrepancy between target shift position and actual shift position | ||||

| Diagnosis delay time | 1.3 seconds | ||||

| 2 | Diagnosis condition | When the ignition switch is ON | |||

| Signal | â | ||||

| Threshold | When the discrepancy of redundant comparison for target shift position | ||||

| Diagnosis delay time | 0.38 seconds | ||||

| 3 | Diagnosis condition | When the ignition switch is ON | |||

| Signal | â | ||||

| Threshold | When the discrepancy of redundant comparison for actual shift position | ||||

| Diagnosis delay time | 0.38 seconds | ||||

POSSIBLE CAUSE

-

Shift actuator

-

TCM

-

Transmission range switch

FAIL-SAFE

-

Shifting operation is prohibited

-

Shift position indicator on combination meter is not displayed

-

Powertrain becomes neutral

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

CHECK DTC PRIORITY

When DTC P0780-00 is displayed together with DTC P18A5-00, diagnose first the DTC P18A5-00.

Is DTC P18A5-00 detected?

YES>>Perform diagnosis of DTC P18A5-00. Refer to DTC Diagnosis Procedure.

NO>>GO TO 2.

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 3.

PERFORM DTC DETECTION

-

Start the engine.

-

Depress the brake pedal.

-

Shift the selector lever to "R" position and wait for 5 seconds or more.

-

Shift the selector lever to "N" position and wait for 5 seconds or more.

-

Shift the selector lever to "D/M" position and wait for 5 seconds or more.

-

Press P position switch.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

REPLACE TRANSAXLE ASSEMBLY

Replace transaxle assembly. Refer to Removal and Installation.

>>

WORK END

P0791-00 Intermediate Speed Sensor a

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0791 | 00 |

Intermediate shaft speed sensor A (Intermediate Shaft Speed Sensor "A" Circuit) |

Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Ignition voltage âĨ 9.01 V b) Battery voltage âĨ 9.01 V |

| Signal | Primary speed sensor signal | |||

| Threshold |

DTC is detected when one of the following conditions a) to b) are satisfied: Primary speed sensor signal voltage: a) 4.311 V âĪ sensor signal < 4.6 V b) 0.108 V âĪ sensor signal < 0.719 V |

|||

| Diagnosis delay time | 0.2 seconds | |||

POSSIBLE CAUSE

-

Harness or connector

-

Primary speed sensor

-

TCM

FAIL-SAFE

-

Lock-up is not performed

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 10 seconds or more.

Shift position : "D" position Nissan Ariya Vehicle speed : 40 km/h (25 MPH) or more CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK PRIMARY SPEED SENSOR CIRCUIT

Check primary speed sensor circuit. Refer to Diagnosis Procedure.

>>

INSPECTION END

P0792-00 Intermediate Speed Sensor a

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0792 | 00 |

Intermediate shaft speed sensor A (Intermediate Shaft Speed Sensor "A" Circuit Range/Performance) |

Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Ignition voltage âĨ 9.01 V b) Battery voltage âĨ 9.01 V c) Range : D d) Input shaft speed > 300 rpm e) Secondary pulley speed > 860 rpm |

| Signal | Primary speed sensor signal | |||

| Threshold |

DTC is detected when one of the following conditions a) to b) are satisfied: a) Current pulse frequency / Last pulse frequency âĨ2 b) Current pulse frequency / Last pulse frequency âĪ1/2 |

|||

| Diagnosis delay time | â | |||

POSSIBLE CAUSE

-

Harness or connector

-

Primary speed sensor (source reading input speed sensor value)

-

TCM

FAIL-SAFE

-

Lock-up is not performed

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 10 seconds or more.

Shift position : "D" position Nissan Ariya Vehicle speed : 40 km/h (25 MPH) or more CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK PRIMARY SPEED SENSOR CIRCUIT

Check primary speed sensor circuit. Refer to Diagnosis Procedure.

>>

INSPECTION END

P0793-00 Intermediate Speed Sensor a

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | |||

| P0793 | 00 |

Intermediate shaft speed sensor A (Intermediate Shaft Speed Sensor "A" Circuit No Signal) |

1 | Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Time passed after changing the range > 2 sec b) Power supply voltage âĨ 10 V |

| Signal | Primary speed sensor signal | ||||

| Threshold |

DTC is detected when all of the following conditions are satisfied: a) Primary pulley speed < 150 rpm b) Secondary pulley speed âĨ 500 rpm |

||||

| Diagnosis delay time | 5 seconds | ||||

| 2 | Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Time passed after changing the range > 2 sec b) Power supply voltage âĨ 10 V |

|||

| Signal | Primary speed sensor signal | ||||

| Threshold |

DTC is detected when all of the following conditions are satisfied: a) Last primary pulley speed âĨ 1000 rpm b) Current primary pulley speed âĪ 240 rpm |

||||

| Diagnosis delay time | 0.5 seconds | ||||

POSSIBLE CAUSE

-

Harness or connector

-

Primary speed sensor

-

TCM

-

Control valve assembly

-

Primary pressure solenoid valve

FAIL-SAFE

-

Lock-up is not performed

-

Stop/start system prohibited*

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 10 seconds or more.

Shift position : "D" position Nissan Ariya Vehicle speed : 40 km/h (25 MPH) or more CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK DTC PRIORITY

When DTC P0793-00 is displayed together with any following DTC, diagnose first the other DTC.

-

P0746-00, P0747-00, P0776-00, P0777-00

Is applicable DTC detected?

YES>>Perform diagnosis of applicable. DTC Index.

NO>>GO TO 2.

CHECK PRIMARY SPEED SENSOR CIRCUIT

Check primary speed sensor circuit. Refer to Diagnosis Procedure.

>>

INSPECTION END

P0794-00 Intermediate Speed Sensor a

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | |||

| P0794 | 00 |

Intermediate shaft speed sensor A (Intermediate Shaft Speed Sensor "A" Circuit Intermittent) |

1 | Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Ignition voltage âĨ 9.01 V b) Battery voltage âĨ 9.01 V |

| Signal | Primary speed sensor signal | ||||

| Threshold |

DTC is detected when all of the following conditions are satisfied: a) Primary pulley turns clock wise. b) Primary pulley speed > 9450 rpm |

||||

| Diagnosis detection time | 2 seconds | ||||

| 2 | Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Ignition voltage âĨ 9.01 V b) Battery voltage âĨ 9.01 V |

|||

| Signal | Primary speed sensor signal | ||||

| Threshold |

DTC is detected when all of the following conditions are satisfied: a) Primary pulley turns counter clock wise. b) Primary pulley speed - < 4730 rpm |

||||

| Diagnosis detection time | 2 seconds | ||||

POSSIBLE CAUSE

-

Harness or connector

-

Primary speed sensor

-

TCM

FAIL-SAFE

Not changed from normal driving

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 10 seconds or more.

Shift position : "D" position Nissan Ariya Vehicle speed : 80 km/h (49 MPH) or more CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK PRIMARY SPEED SENSOR CIRCUIT

Check primary speed sensor circuit. Refer to Diagnosis Procedure.

>>

INSPECTION END

P0796-00 Pressure Control Solenoid C

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | |||

| P0796 | 00 |

Pressure control solenoid C (Pressure Control Solenoid "C" Performance/Stuck Off) |

1 | Diagnosis condition |

When all of the following conditions are satisfied, diagnosis is permitted. a) Ignition voltage âĨ 9.01 V b) Battery voltage âĨ 9.01 V c) -20 °C (-4 °F) âĪ CVT fluid temperature d) Lockup pattern = Lock-up ON or Lock-up OFF |

| Signal | â | ||||

| Threshold |

When all of the following conditions a) to b) are satisfied for the specified period [5sec] continuously. Keep the same conditions for specified period again after interval. a) Secondary pulley sensor pressure < Line pressure sensor pressure - Variation b) Secondary pulley sensor pressure < Secondary pulley sensor instruction pressure - Variation [Interval]

|

||||

| Diagnosis delay time | 5 seconds à 2 count | ||||

| 2 | Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Engine speed: More than 775 rpm b) Shift position: Other than P/N position c) CVT fluid temperature: More than -20â (-4â) d) TCM power supply: More than 11 V e) The difference between instruction pressure of secondary pressure and 10-msec-ago instruction secondary pressure is 0 MPa or more f) Instruction pressure of secondary pressure: 0 MPa or more |

|||

| Signal | â | ||||

| Threshold |

DTC is detected when the following conditions "1" and "2" are satisfied:

|

||||

| Diagnosis delay time | 10 seconds | ||||

| 3 | Diagnosis condition |

Diagnosis is permitted when all of the following conditions are satisfied: a) Engine speed: More than 775 rpm b) Shift position: Other than P/N position c) CVT fluid temperature: More than -20°C (-4°F) d) TCM power supply: More than 11 V e) The difference between instruction pressure of secondary pressure and 10-msec-ago instruction secondary pressure is 0 MPa or more f) Instruction pressure of secondary pressure: 0 MPa or more |

|||

| Signal | â | ||||

| Threshold |

DTC is detected when the following conditions "1" and "2" are satisfied:

|

||||

| Diagnosis delay time | 10 seconds | ||||

POSSIBLE CAUSE

-

Harness or connector

-

Secondary pressure solenoid valve

-

Control valve assembly

-

TCM

FAIL-SAFE

-

Vehicle speed < 40 km/h (25 MPH) or Input speed < 1300 rpm

-

Selector shock is large

-

Start is slow

-

Acceleration is slow

-

Lock-up is not performed

-

-

Other then the above

-

Selector shock is large

-

Start is slow

-

Acceleration is slow

-

Stop/start system prohibited*

-

*: With stop/start system

DTC CONFIRMATION PROCEDURE

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, ignition switch OFF and wait for at least 10 seconds, then perform the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V.

>>

GO TO 2.

PERFORM DTC DETECTION

-

Start the engine.

-

Drive the Nissan Ariya vehicle and maintain the following conditions for 20 seconds or more.

Shift position : "D" position CVT fluid temperature : 25 °C (77 °F) - 120 °C (248 °F) Nissan Ariya Vehicle speed : 40 km/h (25 MPH) or more CAUTION:

Be careful of the driving speed.

-

Stop the Nissan Ariya vehicle.

-

Repeat step 2 to 3.

-

Check the DTC.

Is DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

INSPECT CVT CHAIN BELT