Nissan Rogue Service Manual: Rocker cover

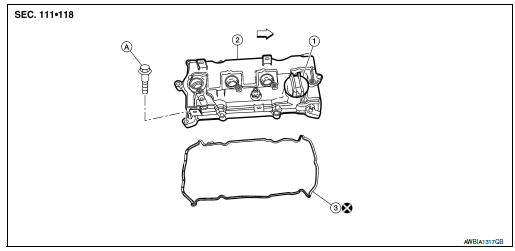

- Oil filler cap

- Rocker cover

- Rocker cover gasket

- Refer to INSTALLATION

Engine front

Engine front

Removal and Installation

REMOVAL

- Remove intake manifold. Refer to EM-26, "Removal and Installation".

- Remove wheel and tire (RH) using a power tool.

- Remove engine under cover. Refer toEXT-37, "ENGINE UNDER COVER : Removal and Installation".

- Remove fender protector side cover. Refer to EXT-28, "FENDER PROTECTOR : Exploded View".

- Remove drive belt. Refer to EM-13, "Removal and Installation".

- Remove the RH engine mount torque rod. Refer to EM-81, "Exploded View".

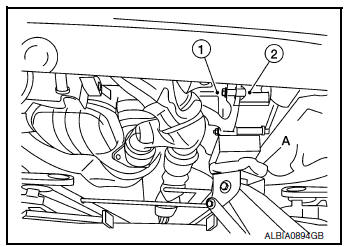

- Use a suitable jack (A) to securely support the bottom of the engine (1) and the transaxle assembly (2).

CAUTION: Put a piece of wood or an equivalent as the supporting surface and secure in a stable condition.

- Remove A/C line bracket bolt.

Engine front

Engine front

- Remove harness grounds from engine mounting bracket (RH).

- Remove harness retainers from engine mounting bracket (RH).

- Remove the engine mounting bracket (RH). Refer to EM-81, "Exploded View"

- Remove the engine mounting bracket (LH). Refer to EM-81, "Exploded View"

- Disconnect the PCV hose.

- Disconnect harness connector from intake valve timing control solenoid valve. Refer to EM-44, "Exploded View"

- Disconnect harness connector from intermediate valve timing control solenoid valve. Refer to EM-44, "Exploded View"

- Disconnect harness connector from exhaust valve timing control solenoid valve. Refer to EM-44, "Exploded View"

- Disconnect harness connector from camshaft position sensors. Refer to EM-64, "Exploded View"

- Remove the spark plugs. Refer to EM-17, "Removal and Installation".

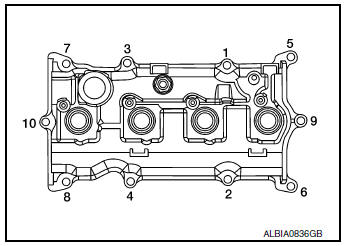

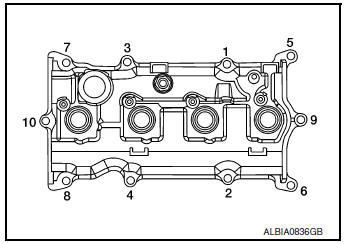

- Loosen the bolts in the numerical order as shown using power tool.

- Remove the rocker cover and the rocker cover gasket. Discard

the rocker cover gasket.

CAUTION: Do not reuse the rocker cover gasket.

- Remove the oil filler cap, (if necessary).

INSTALLATION

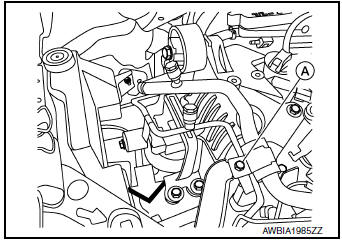

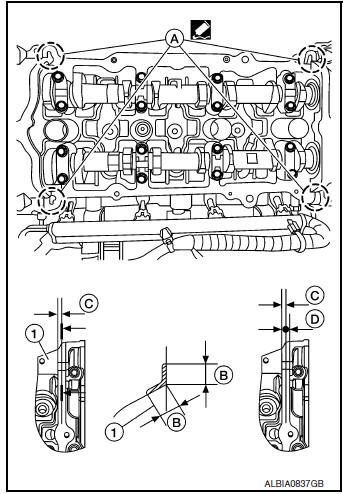

- Apply liquid gasket to the position shown (A) with the following procedure:

- Apply liquid gasket to joint part of No.1 camshaft bracket (1) and cylinder head.

- Apply liquid gasket in a 90° degree angle (B).

- Use Genuine Silicone RTV Sealant, or equivalent. Refer to GI-22, "Recommended Chemical Products and Sealants".

(B) : 10 mm (0.39 in)

(C) : 4 mm (0.16 in)

(D) : 5 mm (0.20 in)

- Install rocker cover gasket to rocker cover.

NOTE: The rocker cover gasket must be securely installed in the groove in the rocker cover.

- Install the rocker cover and rocker cover gasket onto the cylinder head.

- Tighten the rocker cover bolts to specification in two steps in the order shown.

Step 1 : 1.96 N·m (0.20 kg-m, 17 in-lb)

Step 2 : 8.33 N·m (0.85 kg-m, 74 in-lb)

- Installation of the remaining components is in the reverse order of removal.

- Inspect for engine oil leaks. Refer to LU-7, "Inspection".

Ignition coil

Ignition coil

Exploded View

Ignition coil

Spark plug

Rocker cover

Removal and Installation

REMOVAL

Remove air duct assembly. Refer to EM-24, "Exploded View" .

Dis ...

Fuel injector and fuel tube

Fuel injector and fuel tube

Exploded View

Rocker cover

Cylinder head

Fuel tube

Clip

O-ring (green)

Fuel injector

O-ring (black)

Front

Removal and Installation

WARNING:

& ...

Other materials:

Third row seats

Exploded View

Seatback board (RH)

Seatback trim (RH)

Seatback pad (RH)

Seat cushion trim (RH)

Seat cushion pad (RH)

Seat cushion silencer (LH/RH)

Seat hinge finisher (RH)

Gas stay

Bolt cover (RH)

Seat belt buckle (RH)

Seat belt buckle (LH)

Bolt ...

System description

COMPONENT PARTS

Component Parts Location

View under rear of front passenger

seat

View with spare tire cover removed

Center of back door

View with glove box removed

No.

Component

Function

1

Rod antenna

Refer to AV-232, &quo ...

Rear suspension ARM

Exploded View

Rear suspension arm

Rubber washer (LH/RH)

Rear suspension arm bracket

Rear suspension arm stay

Front

Removal and Installation

REMOVAL

Remove the wheel hub and bearing. Refer to RAX-16, "Removal and

Installation".

Remove the coil spring. R ...