Nissan Rogue Service Manual: Parking brake shoe

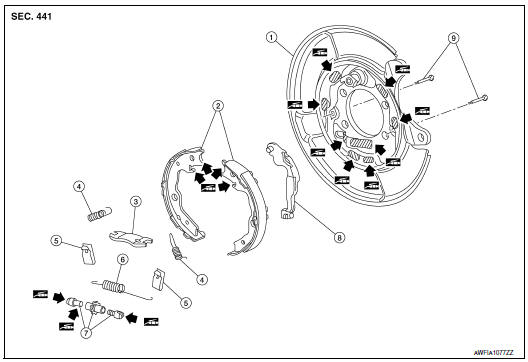

Exploded View

- Back plate

- Parking brake shoe

- Brake strut

- Return spring

- Spring

- Return spring to brake strut

- Adjuster

- Toggle lever

- Anti-rattle pin

: Apply PBC (Poly Butyl

Cuprysil) grease or silicone-based grease

: Apply PBC (Poly Butyl

Cuprysil) grease or silicone-based grease

Removal and Installation

REMOVAL

WARNING: Clean dust on the parking brake shoes with a vacuum dust collector to minimize the hazard of airborne particles or other materials.

- Remove the rear wheel and tire using power tool. Refer to WT-60, "Removal and Installation".

- Remove the brake caliper torque member bolts, leaving the brake

hose attached. Position the caliper

aside with wire. Refer to BR-43, "BRAKE CALIPER ASSEMBLY : Removal and

Installation".

CAUTION: Do not depress the brake pedal while the caliper assembly is removed.

- Put alignment marks on the disc brake rotor and on the wheel hub

and bearing and remove the disc brake

rotor.

CAUTION: Do not drop the disc brake rotor.

- If disc brake rotor cannot be removed, remove as follows:

- Secure the disc brake rotor with wheel nuts and remove the adjusting hole plug.

- Using suitable tool, rotate adjuster (1) in direction (B) to retract and loosen parking brake shoe.

- Remove anti-rattle pins, springs, and return springs.

CAUTION: Do not drop the removed parts.

- Remove brake strut, adjuster, parking brake shoes and toggle lever.

CAUTION:

- The leading parking brake shoes are made of different materials than the trailing parking brake shoes. Do not misidentify them when removing.

- Do not drop the removed parts.

- Remove the back plate. Refer to RAX-7, "Removal and Installation" (FWD) or RAX-16, "Removal and Installation" (AWD).

- Inspect the components. Refer to PB-12, "Inspection".

INSTALLATION

Installation is in the reverse order of the removal.

- Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease to

the back plate and brake shoe.

CAUTION: The leading parking brake shoes are made of different materials than the trailing parking brake shoes. Do not misidentify them when installing.

- Assemble adjusters so that threaded part is expanded when rotating it in the direction shown by arrow.

A: For RH brake

B: For LH brake

: Vehicle front

: Vehicle front

: Adjuster expands

: Adjuster expands

- Shorten adjuster by rotating it.

- When assembling, apply PBC (Poly Butyl Cuprysil) grease or silicone- based grease to threads.

- Check parking brake shoe lining surface and drum inner surface for grease. Wipe off any grease on the surfaces.

- Inspect the parking brake system. Adjust the parking brake system if necessary. Refer to PB-4, "Inspection and Adjustment".

Inspection

INSPECTION AFTER REMOVAL

Brake Lining Thickness Inspection

- Check thickness (A) of brake lining.

Limit (A) : Refer to PB-14, "Parking Drum Brake".

Drum Inner Diameter Inspection

- Check inner diameter (B) of drum using suitable tool.

Limit (B) : Refer to PB-14, "Parking Drum Brake".

Other Inspections

- Check brake lining for excessive wear, damage, and peeling. Replace if necessary.

- Check parking brake shoe for excessive wear and damage. Replace if necessary.

- Check anti-rattle pin for excessive wear, damage and rust. Replace if necessary.

- Check adjuster spring, anti-rattle spring and return springs for

settling, excessive wear, damage, and rust.

Replace if necessary.

- Check brake strut for excessive wear, damage and rust. Replace if necessary.

- Check toggle lever for excessive wear, damage and rust. Replace if necessary.

- Visually check inside of the drum for rust, cracks, damage or excessive wear with a suitable tool. Replace if necessary.

Parking brake switch

Parking brake switch

Removal and Installation

REMOVAL

Remove the instrument lower panel LH. Refer to IP-22, "Removal and

Installation".

Disconnect the harness connector from the parking bra ...

Service data and specifications (SDS)

Service data and specifications (SDS)

Parking Drum Brake

Parking Brake Control

...

Other materials:

P0706 transmission range sensor A

DTC Description

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P0706

T/M RANGE SENSOR A

(Transmission Range Sensor A Circuit Range/

Performance)

When all of the following conditions are satisfied and this state ...

C1130 engine signal

DTC Logic

DTC DETECTION LOGIC

DTC

Display Item

Malfunction detected condition

Possible causes

C1130

ENGINE SIGNAL 1

When a malfunction is detected in ECM system.

ECM

ABS actuator and electric unit

(control unit)

CAN communication l ...

Continuously Variable Transmission (CVT) fluid

CAUTION

NISSAN recommends using Genuine

NISSAN CVT Fluid NS-3 ONLY in

NISSAN CVTs. Do not mix with other

fluids.

Do not use Automatic transmission

fluid (ATF) or Manual transmission fluid

in a NISSAN CVT, as it may damage the

CVT. Damage caused by t ...