Nissan Rogue Service Manual: Replacement operations

Description

- This section is prepared for technicians who have attained a high level of skill and experience in repairing collision-damaged vehicles and also use modern service tools and equipment. Persons unfamiliar with body repair techniques should not attempt to repair collision-damaged vehicles by using this section.

- Technicians are also encouraged to read Body Repair Manual (Fundamentals) in order to ensure that the original functions and quality of the vehicle can be maintained. The Body Repair Manual (Fundamentals) contains additional information, including cautions and warning, that are not including in this manual. Technicians should refer to both manuals to ensure proper repairs.

- Please note that these information are prepared for worldwide usage, and as such, certain procedures might not apply in some regions or countries.

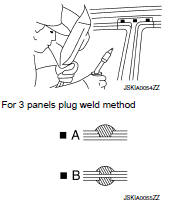

The symbols used in this section for welding operations are shown below.

|

Symbol marks |

Description |

|

|

2-spot welds |  |

|

3-spot welds |  |

|

MIG plug weld |  |

|

MIG seam weld / Point weld | |

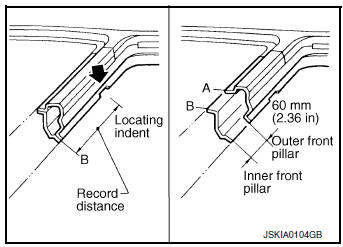

- Front pillar butt joint can be determined anywhere within shaded area as shown in the figure. The best location for the butt joint is at position A due to the construction of the vehicle. Refer to the front pillar section.

- Determine cutting position and record distance from the locating indent. Use this distance when cutting the service part. Cut outer front pillar over 60 mm (2.36 in) above inner front pillar cut position.

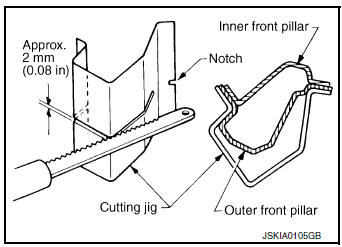

- Prepare a cutting jig to make outer pillar easier to cut. Also, this will permit service part to be accurately cut at joint position.

- An example of cutting operation using a cutting jig is as follows.

- Mark cutting lines.

- Cut position of outer pillar

- Cut position of inner pillar

- Align cutting line with notch on jig. Clamp jig to pillar.

- Cut outer pillar along groove of jig (at position A).

- Remove jig and cut remaining portions.

- Cut inner pillar at position B in same manner.

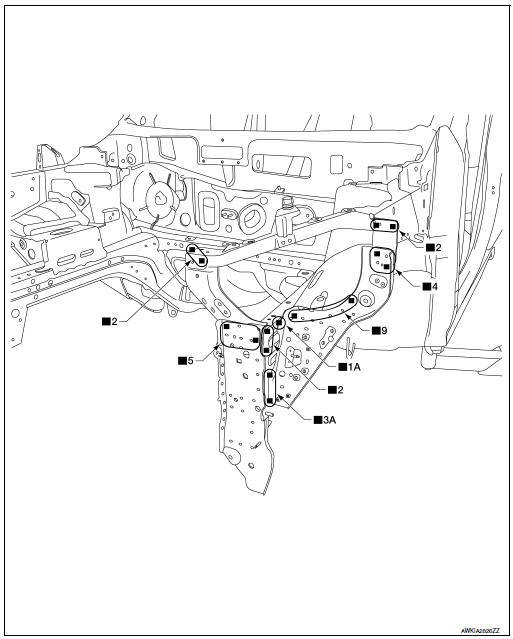

Hoodledge

Replacement parts

- Upper hoodledge (LH)

Front

Front

Hoodledge Reinforcement

Replacement parts

- LH Hoodledge reinforcement

Front

Front

Radiator Core Support Side

Replacement parts

- Radiator core support side

Front

Front

Strut Housing

Replacement parts

- Strut housing

- Strut housing extension

Front

Front

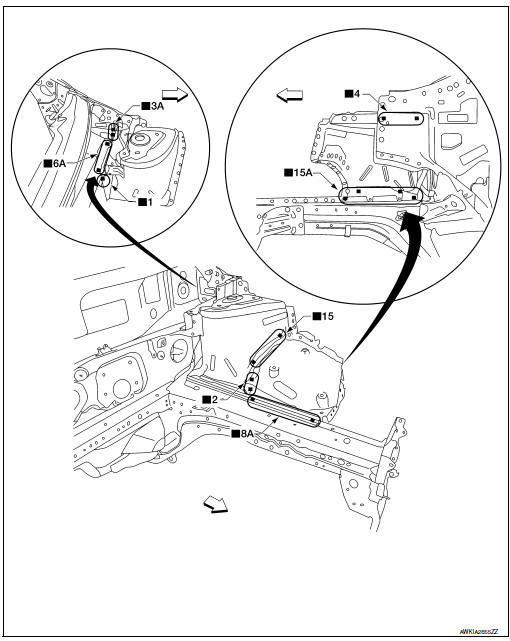

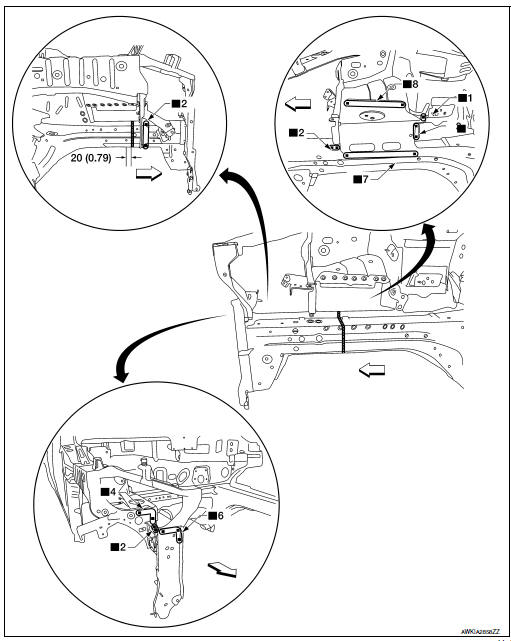

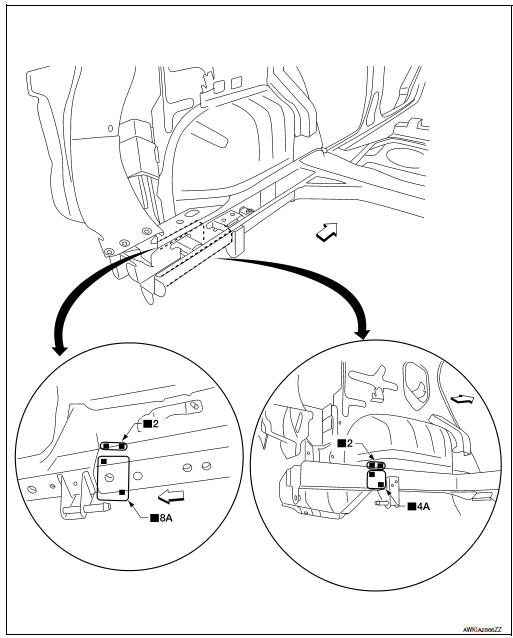

Front Side Member Outer

Work after hoodledge has been removed.

Replacement parts

- Front side member closing plate assembly (LH)

Front

Front

Front Side Member Inner

Work after hoodledge and strut housing has been removed.

Replacement parts

- Front side member inner assembly (LH)

Front

Front

Front Side Member (Partial Replacement)

Replacement parts

- Front side member (RH)

- Front side member closing plate assembly (RH)

Front

Front

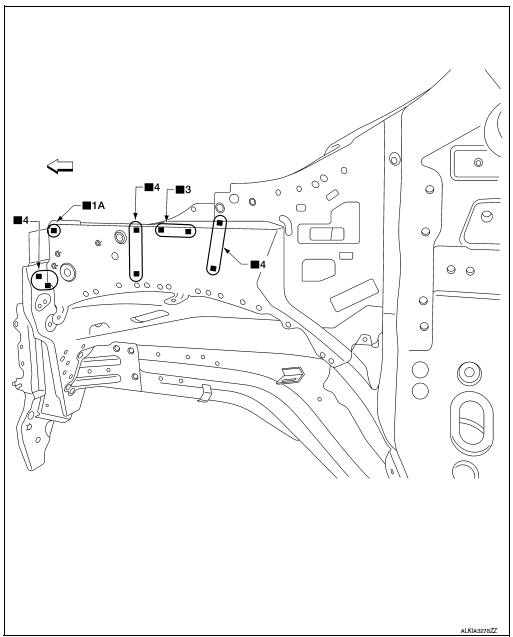

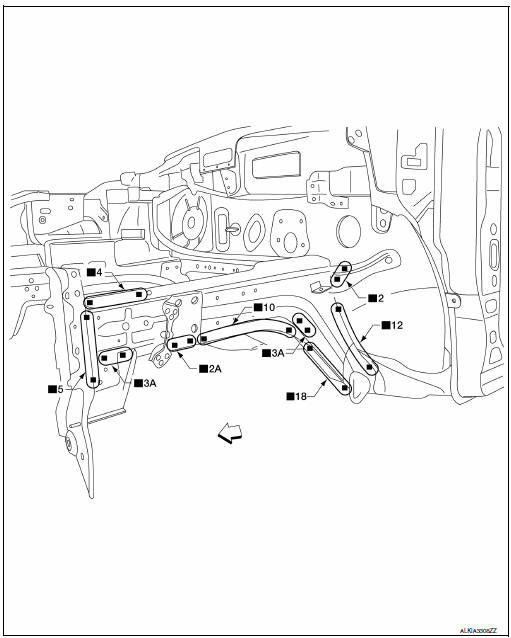

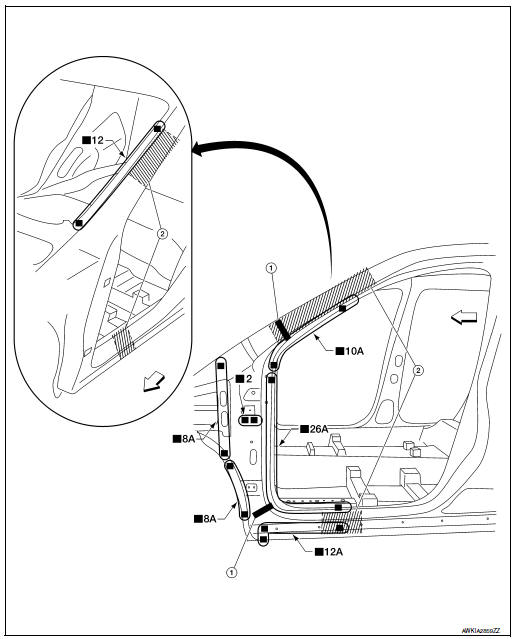

Front Pillar

Work after hoodledge reinforcement has been removed.

Replacement parts

- Front side body (LH)

- Urethane foam

- Sectioning location

Front

Front

View B: Before installing outer front side body

Replacement parts

- Inner front pillar reinforcement

- Urethane foam

Front

Front

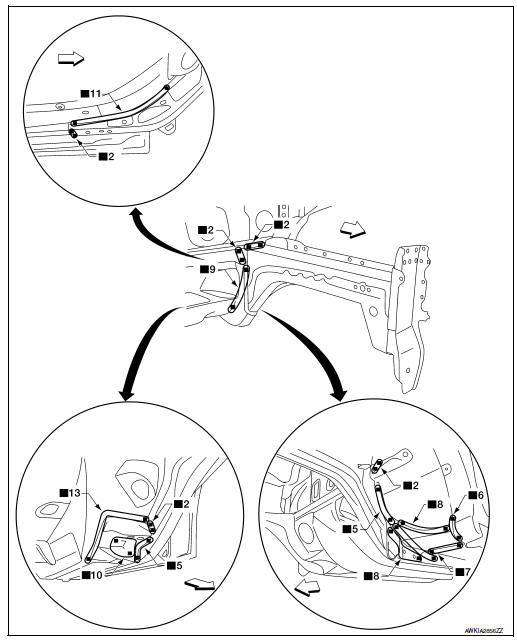

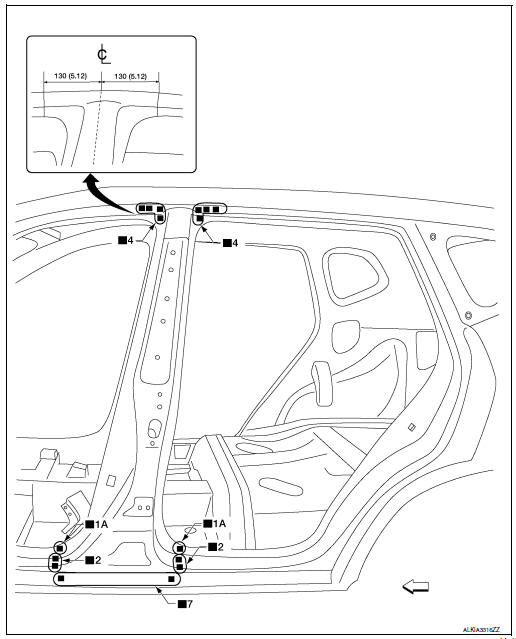

Center Pillar

Replacement parts

- Outer center pillar

Front

Front

Replacement parts

- Center pillar reinforcement

Front

Front

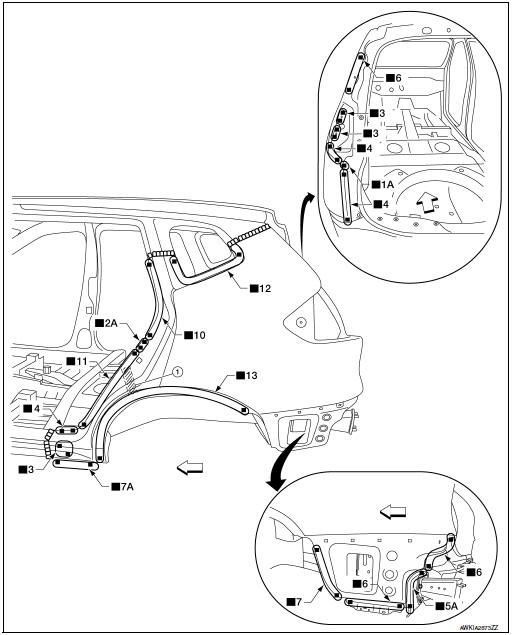

Rear Fender

Replacement parts

- Rear fender assembly (LH)

- Urethane foam

Front

Front

Rear Panel

Replacement parts

- Rear panel assembly

- Bolt

Front

Front

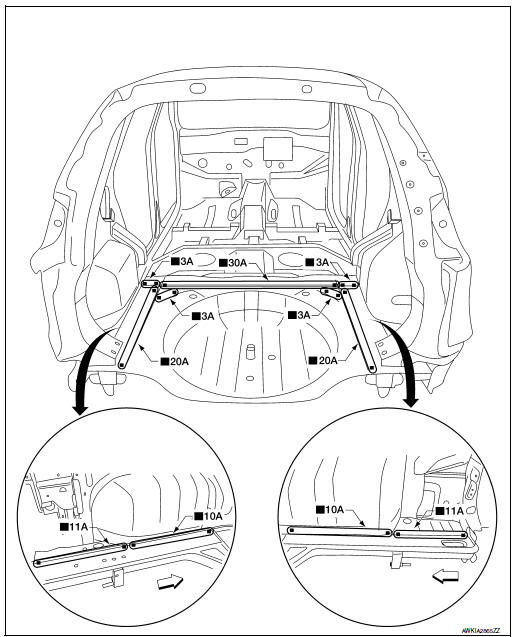

Rear Floor Rear

Work after rear panel has been removed.

Replacement parts

- Rear floor rear

- Rear floor rear side

Front

Front

Rear Side Member Extension

Work after rear panel has been removed.

Replacement parts

- Rear side member extension (LH)

Front

Front

Body construction

Body construction

Body Construction

Outer body side

Outer front pillar reinforcement

Upper inner front pillar

Rear hoodledge reinforcement

Side dash

Inner front pillar reinforcement

Lower ...

Service data and specifications (SDS)

Service data and specifications (SDS)

BODY ALIGNMENT

Body Center Marks

mark has been placed on each part of the body to indicate the vehicle center.

When repairing parts damaged

by an accident which might affect the vehicle frame (me ...

Other materials:

On board diagnostic (OBD) system

Diagnosis Description

This system is an on board diagnostic system that records exhaust

emission-related diagnostic information

and detects a sensors/actuator-related malfunction. A malfunction is indicated

by the malfunction indicator

lamp (MIL) and stored in control module memory as a DTC. ...

Component parts

Component Parts Location

Engine room (RH)

View with transmission removed

View with engine and transmission removed

Behind instrument panel (LH)

No.

Component part

Description

1

IPDM E/R

CPU inside IPDM E/R operates the starter relay when the ignition

...

P0461 fuel level sensor

DTC Description

DTC DETECTION LOGIC

Driving long distances naturally affect fuel gauge level.

This diagnosis detects the fuel gauge malfunction of the gauge not moving even

after a long distance has

been driven.

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC de ...