Nissan Rogue Service Manual: Removal and installation

GENERATOR

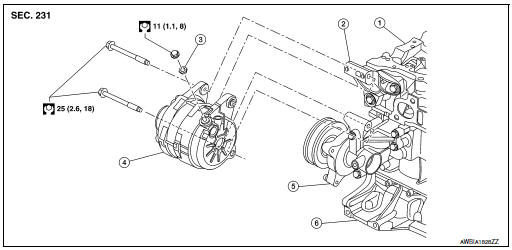

Exploded View

REMOVAL

- Cylinder head

- Generator bracket

- Washer

- Generator

- Water pump

- Cylinder block

Removal and Installation

REMOVAL

- Disconnect negative terminal from battery. Refer to PG-75, "Exploded View".

- Remove wheel and tire (RH) using a power tool. Refer to WT-60, "Removal and Installation".

- Remove fender protector side cover. Refer to EXT-28, "FENDER PROTECTOR : Exploded View"

- Remove front air spoiler. Refer to EXT-16, "Exploded View".

- Remove engine under cover. Refer to EXT-37, "ENGINE UNDER COVER : Removal and Installation".

- Remove drive belt. Refer to EM-13, "Removal and Installation".

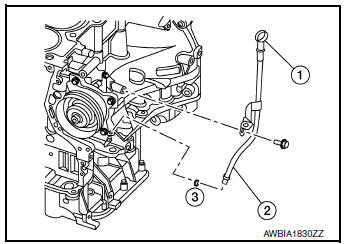

- Remove oil level gauge (1).

- Remove oil level gauge guide (2).

- Remove oil level gauge guide O-ring (3).

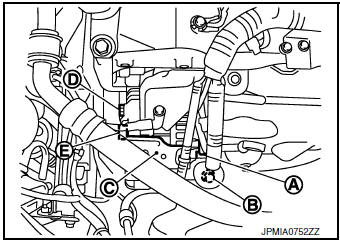

- Disconnect generator connector (A).

- Remove “B” terminal nut (B) and “B” terminal harness.

- Remove harness bracket (C).

NOTE: Harness ground does not have to be removed during bracket removal.

- Remove upper generator mounting bolt (D), using suitable tool.

- Remove lower generator mounting bolt (E), using suitable tool.

- Remove generator upward from the vehicle.

INSTALLATION

Installation is in the reverse order of removal.

- Tighten oil level gauge guide bolt to specification.

Oil level gauge guide bolt : 21.6 N·m (2.2 kg-m, 16 ft-lb)

CAUTION:

- Be careful to tighten “B” terminal nut carefully.

- Install generator and check tension of belt. Refer to EM-13, "Checking".

- Do not reuse oil level gauge guide O-ring.

- Prior to installation, apply clean engine oil to oil level gauge guide O-ring.

- Ensure O-ring sealing surface is free from dust or imprefections.

- Allow engine to run for 5 minutes and inspect for engine oil leaks.

Inspection

GENERATOR PULLEY INSPECTION

Perform the following.

- Make sure that the generator pulley does not bind or rattle.

- Make sure that the generator pulley is tight. Refer to CHG-20, "Exploded View".

Symptom diagnosis

Symptom diagnosis

CHARGING SYSTEM

Symptom Table

...

Service data and specifications (SDS)

Service data and specifications (SDS)

Generator

...

Other materials:

Removal and installation

FRONT COMBINATION LAMP

Exploded View

Front fender

Front combination lamp

Clip

Removal and Installation

REMOVAL

Remove front bumper fascia. Refer to EXT-17, "Removal and

Installation".

Remove front combination lamp bolts and clip.

Pull front combinat ...

Engine compartment

CAUTIONNever use a fuse of a higher or lower

amperage rating than specified on the

fuse box cover. This could damage the

electrical system or cause a fire.

Two types of fuses are used. Type A is used in

the fuse boxes in the engine compartment. Type

B is used in the passe ...

System description

DESCRIPTION

Engine Cooling System

Thermostat

Water outlet

Cylinder block (Thermostat housing)

Water inlet

Radiator

Water pump

Cylinder block

Cylinder head

Open

Closed

To electric throttle control actuator

To oil cooler

...