Nissan Rogue (T33) 2021-Present Service Manual: P052a Intake Valve Timing Control

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) | DTC detection condition | ||

|---|---|---|---|---|

| P052A | 00 |

CAMSHAFT POSITION TIMING B1 (Cold start ŌĆ£AŌĆØ camshaft position timing over-advanced bank 1) |

Diagnosis condition | Cold condition |

| Signal (terminal) | ŌĆö | |||

| Threshold | There is a gap between angle of target and phase-control angle degree when the engine is in a cold condition. | |||

| Diagnosis delay time | ŌĆö | |||

POSSIBLE CAUSE A

-

Intake valve timing control actuator

-

Intake valve timing control motor

-

Camshaft sprocket (INT)

-

Wear or damage of the electric intake valve timing control actuator brush

-

Center target

POSSIBLE CAUSE B

-

Accumulation of debris to the signal plate of the camshaft

-

Timing chain installation

FAIL-SAFE

Engine Control System

| Fail safe mode | Nissan Ariya Vehicle behavior | |

|---|---|---|

| Device fix mode |

|

|

Stop/Start System

When a DTC is detected, the stop/start indicator lamp blinks slowly and the stop/start system operation is prohibited. When ECM detects error while operating the stop/start system, ECM restarts the engine.

DTC Confirmation Procedure

PRECONDITIONING

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is 10 V or more at idle.

With CONSULT

With CONSULT

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Turn ignition switch ON.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Turn ignition switch ON.

-

On the CONSULT screen, select ŌĆ£ENGINEŌĆØ >> ŌĆ£DATA MONITORŌĆØ >> ŌĆ£COOLANT TEMP/SŌĆØ.

-

Check ŌĆ£COOLANT TEMP/SŌĆØ indication value.

With GST

With GST

Follow the procedure ŌĆ£With CONSULTŌĆØ above.

Is the value of ŌĆ£COOLANT TEMP/SŌĆØŌłÆ5┬░C (23┬░F) and 45┬░C (113┬░F)?

YES>>GO TO 2.

NO-1 [if it is below ŌłÆ5┬░C (23┬░F)]>>Warm up the engine until the value of ŌĆ£COOLANT TEMP/SŌĆØ indicates ŌłÆ5┬░C (23┬░F) and 45┬░C (113┬░F). And then GO TO 2.

NO-2 [if it is above 45┬░C (113┬░F)]>>Cool the engine down to the value of ŌĆ£COOLANT TEMP/SŌĆØ indicates ŌłÆ5┬░C (23┬░F) and 45┬░C (113┬░F). And then GO TO 2.

PERFORM DTC CONFIRMATION PROCEDURE

-

Turn ignition switch OFF and wait at 10 seconds.

-

Turn ignition switch ON.

-

Set the selector lever in N range.

-

Start the engine and let it idle for 20 seconds or more.

-

Check 1st trip DTC.

Is 1st trip DTC detected?

YES>>Proceed to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

MALFUNCTION A

CAUTION:

Never reuse O-ring of electric intake valve timing control actuator. When replacing the electric intake valve timing control actuator, replace the O-ring.

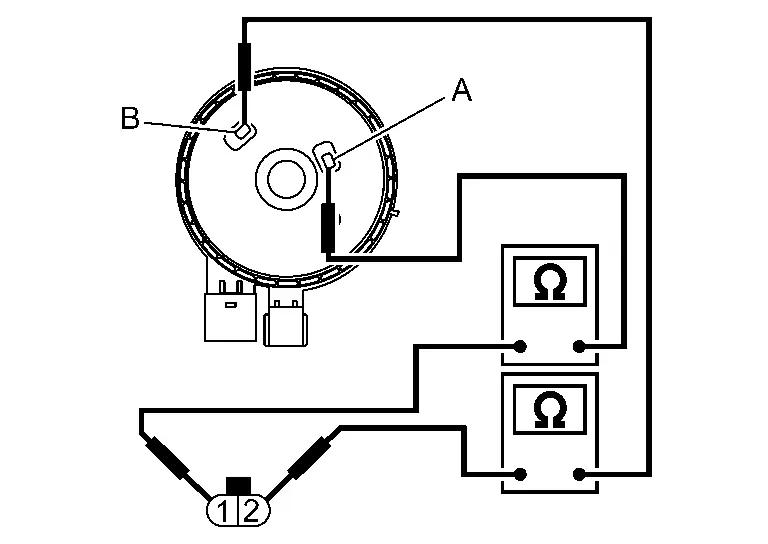

CHECK ELECTRIC INTAKE VALVE TIMING CONTROL MOTOR CONTROL CIRCUIT

-

Turn ignition switch OFF.

-

Disconnect electric intake valve timing control motor harness connector.

-

Disconnect electric intake valve timing control module harness connector.

-

Check the continuity between the electric intake valve timing control motor harness connector and the electric intake valve timing control module harness connector.

Electric intake valve timing control motor Electric intake valve timing control module Continuity Connector Terminal Connector Terminal F91 1 F113 46 Existed 2 42 -

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES>>GO TO 2.

NO>>Repair or replace error-detected parts.

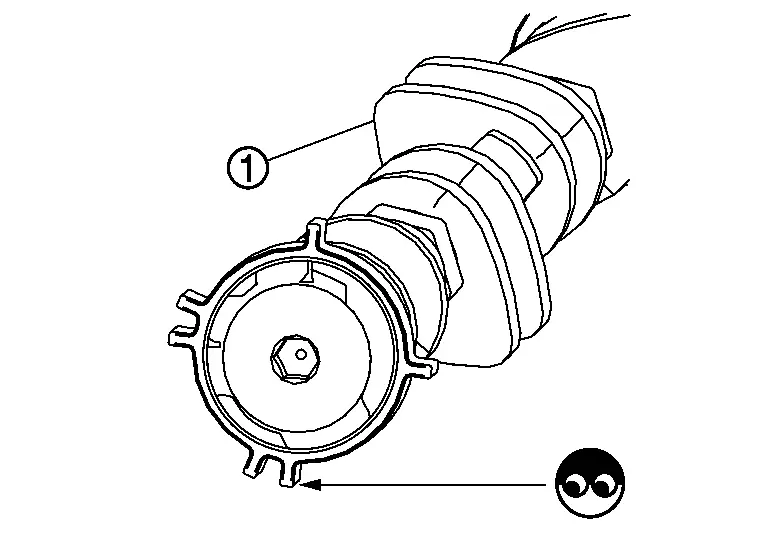

CHECK ELECTRIC INTAKE VALVE TIMING CONTROL ACTUATOR BRUSH

-

Remove electric intake valve timing control actuator. Refer to Exploded View.

-

Check the state of brush for the electric intake valve timing control actuator.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Replace the electric intake valve timing control actuator. Refer to Exploded View.

CHECK ELECTRIC INTAKE VALVE TIMING CONTROL ACTUATOR

-

Check the continuity between electric intake valve timing control actuator connector terminal and brush as following.

Electric intake valve timing control actuator Continuity Terminal Brush 1 A Existed B Not existed 2 B Existed A Not existed

Is the inspection result normal?

YES>>GO TO 4.

NO>>Replace the electric intake valve timing control actuator. Refer to Exploded View.

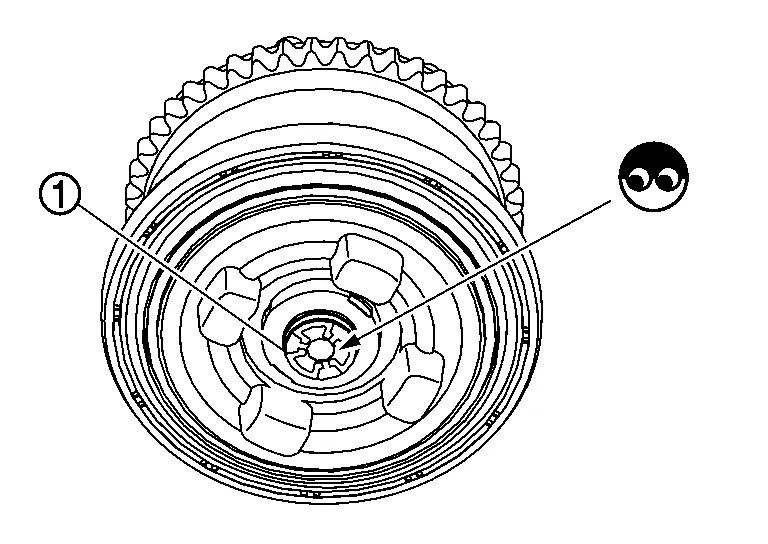

CHECK CENTER TARGET

Check the state of center target .

.

Is the inspection result normal?

YES>>Replace camshaft sprocket (INT) (Electric intake valve timing motor is built-in). Refer to Exploded View.

NO>>Repair or replace the center target. Refer to Exploded View.

MALFUNCTION B

CHECK TIMING CHAIN INSTALLATION

Check service records for any recent repairs that may cause timing chain misalignment.

Are there any service records that may cause timing chain misalignment?

YES>>Check timing chain installation. Refer to Removal and Installation.

NO>>GO TO 2.

CHECK CAMSHAFT SPROCKET AND TIMING CHAIN

Check the following.

-

Visually check for chipping camshaft

sprocket gear tooth.

sprocket gear tooth.

-

Timing chain tension and elongation.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Repair or replace error-detected parts.

Other materials:

Transfer: Ty92a. System Description

Component Parts

Kr15ddt

Component Parts Location

A.

Transfer case assembly

B.

Rear final drive assembly

No. Component Function

1.

Drive mode switch

Refer to Component Parts Location for detailed component location.

2.

Chassis control module

Chassis contro ...

Intelligent Key Interlock Function (with Navigation System)

System Description

SYSTEM DIAGRAMINPUT SIGNAL AND OUTPUT SIGNAL Component Function

BCM

Recognizes the following status and transmits it to driver seat control unit via CAN communication:

Ignition ON signal

Door lock status signal (with Intelligent Key, front door request switch op ...

Symptom Diagnosis. Squeak and Rattle Trouble Diagnoses

Work Flow

CUSTOMER INTERVIEWInterview

the customer if possible, to determine the conditions that exist when

the noise occurs. Use the Diagnostic Worksheet during the interview to

document the facts and conditions when the noise occurs and any of

customer's comments. Refer to Diagnostic Work ...