Nissan Rogue Service Manual: Oil seal

VALVE OIL SEAL

VALVE OIL SEAL : Removal and Installation

REMOVAL

- Remove camshafts. Refer to EM-64, "Removal and Installation".

- Remove valve lifters. Refer to EM-56, "Disassembly and Assembly".

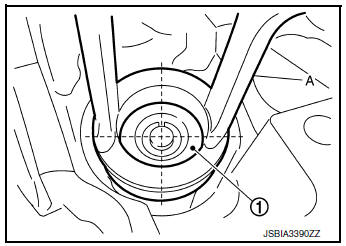

- Rotate crankshaft, and set piston whose valve oil seal is to be

removed to TDC. This will prevent valve

from dropping into cylinder.

CAUTION: When rotating crankshaft, be careful to avoid scarring front cover with timing chain.

- Remove valve collet.

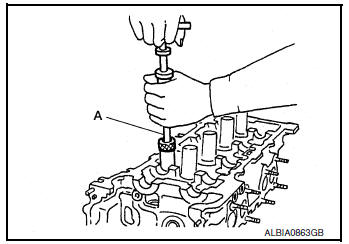

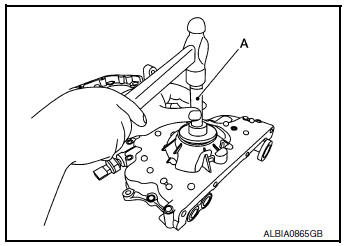

- Compress valve spring using suitable tool (A). Remove valve collet with a magnet.

CAUTION:

- Be careful not to damage valve lifter holes.

- Install suitable tool (A) in the center of valve spring retainer (1) to press it.

- Remove valve spring retainer and valve spring (with valve spring seat).

CAUTION: Do not remove valve spring seat from valve spring.

- Remove valve oil seal using suitable tool (A).

INSTALLATION

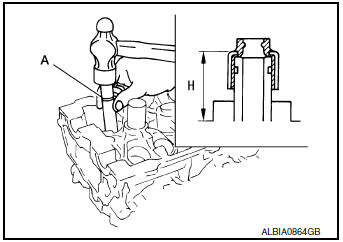

- Apply new engine oil to valve oil seal joint surface and seal lip.

- Press in valve oil seal to the height “H” as shown using suitable tool (A).

Height “H” : Refer to EM-118, "Cylinder Head"

- Installation of the remaining components is in the reverse order of removal

FRONT OIL SEAL

FRONT OIL SEAL : Removal and Installation

REMOVAL

- Remove engine undercover. Refer to EXT-37, "ENGINE UNDER COVER : Removal and Installation".

- Remove front fender protector. Refer to EXT-28, "FENDER PROTECTOR : Removal and Installation".

- Remove drive belt. Refer to EM-13, "Removal and Installation".

- Remove crankshaft pulley (1) using the following procedure:

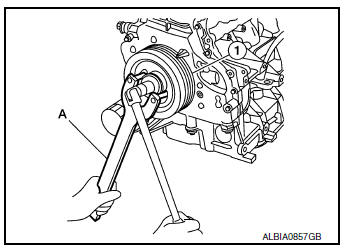

- Hold the crankshaft pulley (1) using suitable tool (A), then loosen and remove the crankshaft pulley bolt.

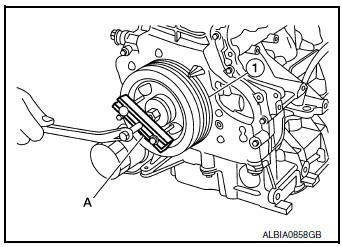

- Attach suitable tool (A) in the threaded hole on crankshaft pulley (1), and remove crankshaft pulley.

- Remove front oil seal with a suitable tool.

CAUTION: Do not damage front cover and crankshaft.

INSTALLATION

- Apply new engine oil to seal lip.

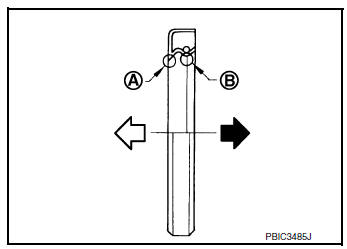

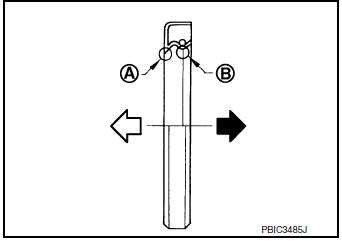

- Install front oil seal so that each seal lip is oriented as shown.

(A) : Dust seal lip

(B) : Oil seal lip

: Engine outside

: Engine outside

: Engine inside

: Engine inside

- Press-fit front oil seal until it is flush with front end surface of front cover using a suitable drift (A).

CAUTION:

- Do not damage front cover and crankshaft.

- Press-fit oil seal straight to avoid causing burrs or tilting.

- Do not touch the grease applied to the oil seal lip.

- Do not reuse oil seal.

- Insert crankshaft pulley by aligning with crankshaft key.

- Tap its center with a plastic hammer to insert.

- Do not tap the crankshaft pulley outer diameter.

- Tighten crankshaft pulley bolt.

- Secure crankshaft pulley with suitable tool to tighten the bolt.

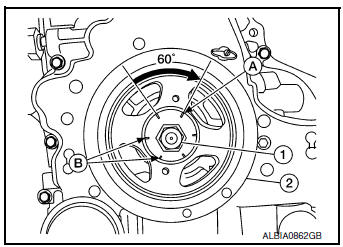

- Perform angle tightening with the following procedure.

- Apply new engine oil to threads and seat surfaces of bolts.

- Apply a paint mark (A) on the front cover, mating with any one of six easy to recognize stamp marks on bolt flange (B).

- Tighten crankshaft bolt (1) to specification.

NOTE: Check that the assembled unit does not interfere with adjacent components by turning the crankshaft in the tightening direction.

Step 1 : 42.1 N·m (4.3 kg-m, 31 ft-lb)

Step 2 : Turn crankshaft bolt (1) an additional 60° +6°/

-0°.

- Installation of the remaining components is in the reverse order of removal.

REAR OIL SEAL

REAR OIL SEAL : Removal and Installation

REMOVAL

- Remove the engine and transaxle. Refer to EM-81, "Removal and Installation (FWD)" and EM-85, "Removal and Installation (AWD)".

- Separate engine from transaxle.

- Remove drive plate. Refer to EM-92, "Exploded View".

- Remove rear oil seal with a suitable tool.

CAUTION: Be careful not to damage crankshaft and cylinder block.

INSTALLATION

- Apply new engine oil to rear oil seal lip.

- Install rear oil seal so that each seal lip is oriented as shown.

(A) : Dust seal lip

(B) : Oil seal lip

: Engine outside

: Engine outside

: Engine inside

: Engine inside

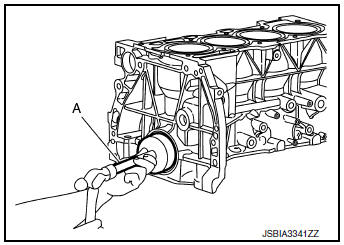

- Press-fit rear oil seal with a suitable drift.

CAUTION:

- Do not damage crankshaft and cylinder block.

- Press-fit oil seal straight to avoid causing burrs or tilting.

- Do not touch grease applied onto oil seal lip.

- Apply neutral detergent (if needed) to outer circumference of oil seal to aid installation. Do not allow detergent to contact inner circumference of oil seal.

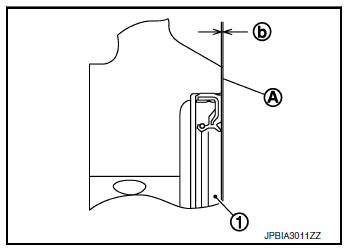

- Press in the new rear oil seal (1) to the position as shown.

(A) : Rear end surface of cylinder block

(b) : 0.0 mm - 0.5 mm (0.000 in - 0.020 in)

- Installation of the remaining components is in the reverse order of removal.

Valve timing control

Valve timing control

Exploded View

Valve timing cover

2. O-rings

Intake valve timing intermediate

lock control solenoid valve

Intake valve timing control solenoid

valve

Exhaust valve timi ...

Unit removal and installation

Unit removal and installation

ENGINE ASSEMBLY

Exploded view

Engine mounting insulator (RH)

Upper torque rod (RH)

Engine mounting bracket (RH)

Lower torque rod

Torque rod bracket

Engi ...

Other materials:

TPMS

Symptom Table

LOW TIRE PRESSURE WARNING LAMP SYMPTOM CHART

Diagnosis

items

Symptom

(Power switch ON)

Low tire pressure warning lamp

Cause

Action

Low tire pressure

warning

lamp

The low tire pressure

warning lamp

illuminates for 1

second, then turn ...

Body construction

Body Construction

Outer body side

Outer front pillar reinforcement

Upper inner front pillar

Rear hoodledge reinforcement

Side dash

Inner front pillar reinforcement

Lower front pillar hinge brace

Upper hinge plate

Weld nut

Upper dash

Upper steering membe ...

Front wiper does not operate

Description

The front wiper does not operate under any operation conditions.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to WW-22, "Wiring Diagram".

1. CHECK WIPER RELAY OPERATION

CONSULT ACTIVE TEST

Select FR WIPER of BCM (WIPER) active test item.

&nb ...