Nissan Rogue Service Manual: Key interlock cable

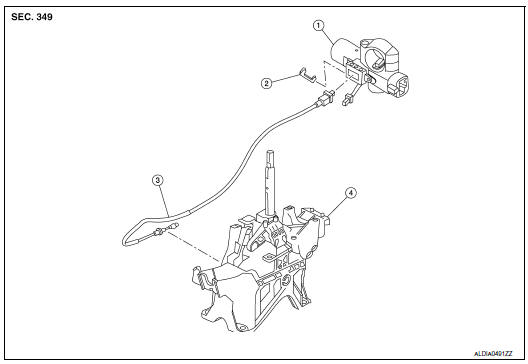

Exploded View

- Key cylinder

- Clip

- Key interlock cable

- Shift selector assembly

Removal and Installation

REMOVAL

CAUTION: Always apply the parking brake before performing removal and installation.

- Move shift selector to the “N” position.

- Remove the shift selector knob.

- Move shift selector to the “P” position.

- Remove the center console assembly. Refer to IP-18, "Removal and Installation".

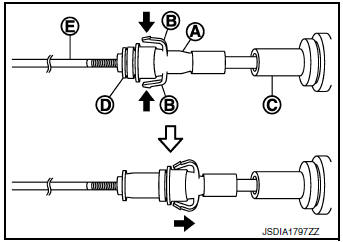

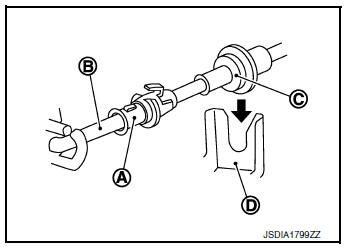

- Press the pawls (B) of the key interlock cable slider (A) while sliding it in the direction of the casing cap (C), and separate the adjusting holder (D) and slider.

(E) :Key interlock rod

- Remove the key interlock cable from the shift selector.

- Remove the steering column covers. Refer to IP-17, "Removal and Installation".

- Remove instrument lower panel LH. Refer to IP-22, "Removal and Installation".

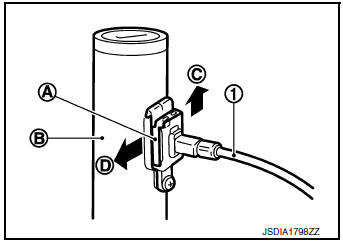

- Lift clip (A) in the direction of the arrow (

C) and remove in the

direction of the arrow (

C) and remove in the

direction of the arrow (  D).

D).

(1) :Key interlock cable

(B) :Key cylinder

- Disconnect the key interlock cable from the key cylinder.

- Disengage the clip and disconnect the key interlock cable from the vehicle.

INSTALLATION

Installation is in the reverse order of removal.

- While pressing the detent rod (B) down ( ), slide the key interlock cable slider (A) toward the key interlock rod (D) side, and install the adjusting holder (C) and key interlock rod.

CAUTION:

- Do not squeeze the pawls on the key interlock cable slider when holding the slider.

- Do not apply force in a perpendicular direction to the key interlock rod when sliding the slider.

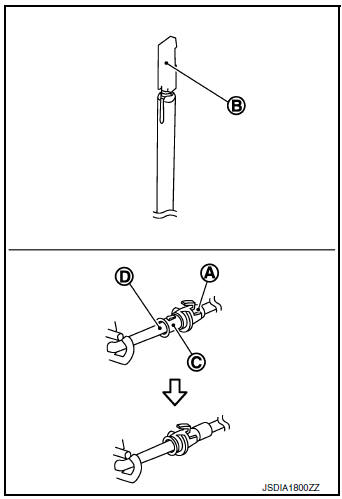

- Install the adjusting holder (A) onto the key interlock rod (B), then install the casing cap (C) onto the shift selector cable bracket (D).

CAUTION:

- When installing the key interlock cable, do not bend or twist the cable forcefully.

- After connecting the key interlock cable to the shift selector cable bracket, be sure to check that the casing cap is completely fastened to the cable bracket. If the casing cap is easily displaced, replace the key interlock cable.

Inspection

INSPECTION AFTER INSTALLATION

- Check the CVT position. If a malfunction is found, adjust the CVT position. Refer to TM-92, "Inspection".

- The key can be removed only when the selector lever is in the “P” position.

- It must not be possible to turn the ignition switch to LOCK when the selector lever is not in the “P” position

Control cable

Control cable

Exploded View

Shift selector

Control cable

Retainer grommet

Lock plate

Bracket

Manual lever

Transaxle assembly

Front

Removal and Installation

CAUTION:

Always apply ...

TCM

TCM

Exploded View

Bracket

Bracket

TCM

: Vehicle front

: N·m (kg-m, in-lb)

Removal and Installation

CAUTION:

Do not impact the TCM when removing or installing TCM.

Wh ...

Other materials:

Parking brake rear cable

Removal and Installation

REMOVAL

Remove the center console assembly. Refer to IP-18, "Removal and

Installation".

Remove shift selector. Refer to TM-194, "Removal and

Installation".

Remove the bolts from the parking brake front cable mount. Refer

...

Preparation

Special Service Tool

The actual shape of the tool may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name

Description

KV991J0080

(J-45741)

ABS active wheel sensor tester

Checking operation of ABS active wheel sensors

Comm ...

Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

DETAILED FLOW

1.COLLECT THE INFORMATION FROM THE CUSTOMER

Get the detailed information from the customer about the symptom (the

condition and the environment when

the incident/malfunction occurred) using the diagnosis worksheet.

>> GO TO 2.

2. ...