Nissan Rogue Service Manual: Front wiper auto stop signal circuit

Component Function Check

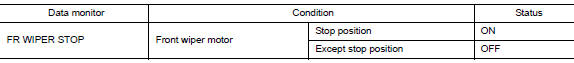

1. CHECK FRONT WIPER (AUTO STOP) SIGNAL

- Select FR WIPER STOP of BCM (WIPER) data monitor item.

- Operate the front wiper.

- Check that FR WIPER STOP changes from ON to OFF according to the wiper position

Is the inspection result normal? YES >> Front wiper auto stop signal circuit is normal.

NO >> Refer to WW-40, "Diagnosis Procedure".

Diagnosis Procedure

Regarding Wiring Diagram information, refer to WW-22, "Wiring Diagram".

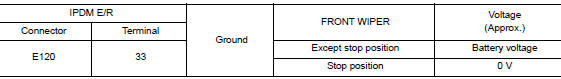

1. CHECK FRONT WIPER MOTOR (AUTO STOP) OUTPUT VOLTAGE

- Turn the ignition switch ON.

- Check voltage between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> Check for intermittent failure.

NO >> GO TO 2.

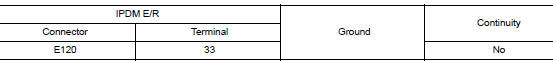

2. CHECK FRONT WIPER MOTOR (AUTO STOP) SHORT CIRCUIT

- Turn the ignition switch OFF.

- Disconnect IPDM E/R and front wiper motor.

- Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> Repair or replace harness.

NO >> GO TO 3.

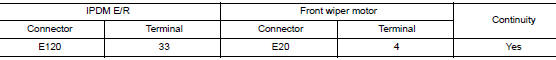

3. CHECK FRONT WIPER MOTOR (AUTO STOP) CIRCUIT CONTINUITY

Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

Is the inspection result normal?

YES >> Replace front wiper motor. Refer to WW-67, "Removal and Installation".

NO >> Repair or replace harness.

Front wiper motor HI circuit

Front wiper motor HI circuit

Component Function Check

1.CHECK FRONT WIPER HI OPERATION

CONSULT ACTIVE TEST

Select FR WIPER of BCM (WIPER) active test item.

Check front wiper operation.

HI : Front wiper (HI ...

Front wiper motor ground circuit

Front wiper motor ground circuit

Diagnosis Procedure

Regarding Wiring Diagram information, refer to WW-22, "Wiring Diagram".

1. CHECK FRONT WIPER MOTOR GROUND CIRCUIT

Turn the ignition switch OFF.

Discon ...

Other materials:

Unit removal and installation

FRONT SUSPENSION MEMBER

Exploded View

Front suspension member

Strut mounting bearing

Rebound stopper insulator

Rebound stopper

Removal and Installation

REMOVAL

Remove the wheel and tire using power tool. Refer to WT-60,

"Removal and Installation&quo ...

Precaution

Precaution for supplemental restraint system (srs) "air bag" and "seat

belt

pre-tensioner"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

...

Checking engine oil level

Checking engine oil level

Park the vehicle on a level surface and apply

the parking brake.

Start the engine and let it idle until it reaches

operating temperature.

Turn off the engine. Wait more than

10 minutes for the oil to drain back into

the oil pan.

Remov ...