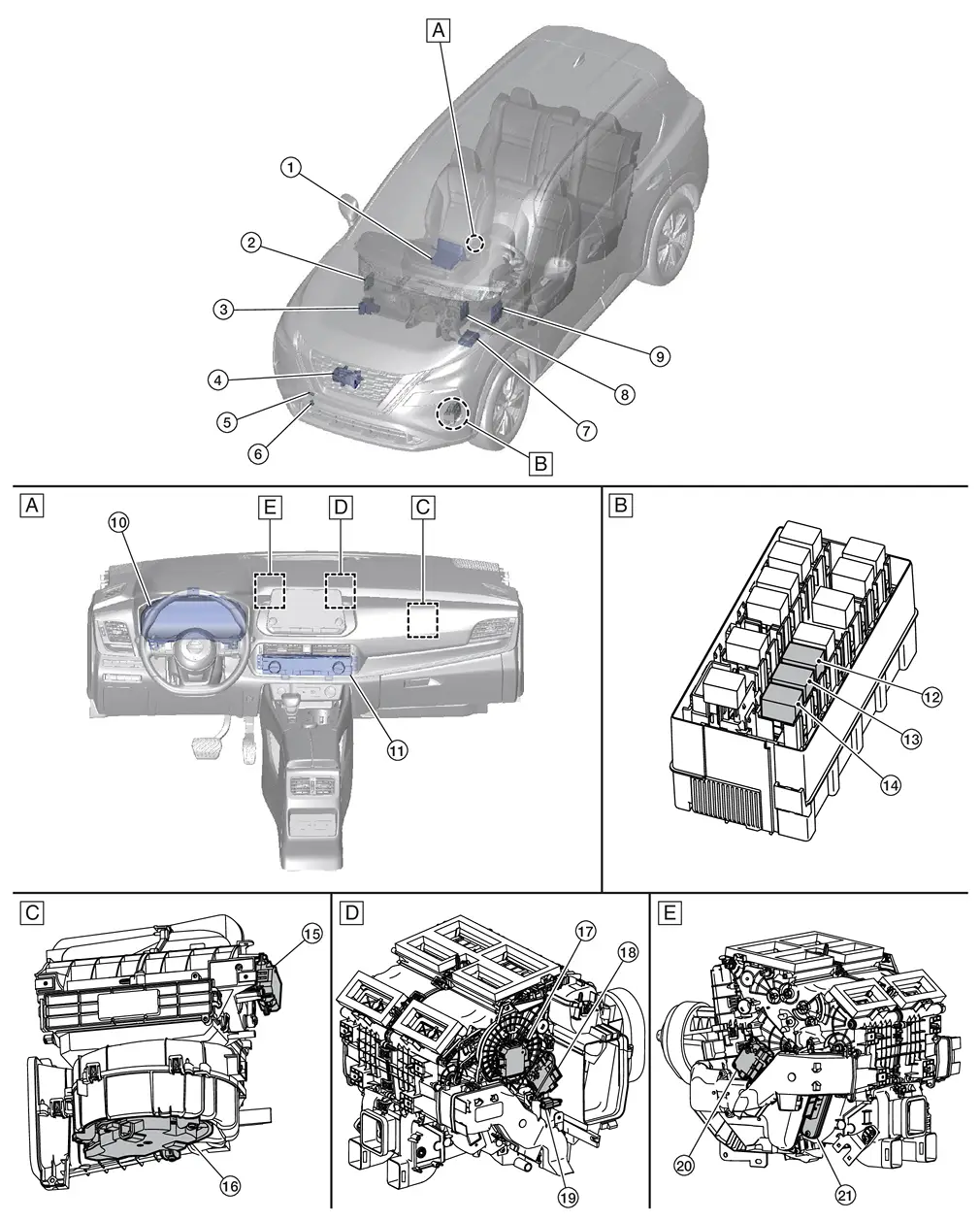

Nissan Rogue (T33) 2021-Present Service Manual: Component Parts

Manual Air Conditioning System

Component Parts Location

| A. | Instrument panel | B. | Left front of Nissan Ariya vehicle | C. | Right side of blower unit assembly |

| D. | Right side of heater and cooling unit assembly | E. | Left side of heater and cooling unit assembly |

| No. | Component | Function |

|---|---|---|

| 1. | AV control unit | Refer to Component Parts Location for detailed component location. |

| 2. | A/C Amp. | Refer to A/C Amp.. |

| 3. |

ABS actuator and electric unit (control unit) [Anti-lock Braking System actuator and electric unit (control unit)] |

Transmits Nissan Ariya vehicle speed signal to A/C Amp. via CAN communication line. Refer to Component Parts Location for detailed component location. |

| 4. | A/C compressor | Refer to A/C Compressor. |

| 5. | Refrigerant pressure sensor | Refer to Refrigerant Pressure Sensor. |

| 6. | Ambient sensor | Refer to Ambient Sensor. |

| 7. | IPDM E/R |

Transmits/receives A/C compressor request and feedback signals between A/C Amp. and ECM via CAN communication line. Refer to Component Parts Location for detailed component location. |

| 8. | ECM (Engine Control Module) |

Receives A/C ON signal and blower fan ON signal from A/C amp., transmits A/C compressor request signal to IPDM E/R via CAN communication line. Refer to Component Parts Location for detailed component location. |

| 9. | BCM (Body Control Module) | Refer to Component Parts Location for detailed component location. |

| 10. | Combination meter |

Transmits ambient temperature signal to A/C amp. via CAN communication line. Refer to Component Parts Location for detailed component location. |

| 11. | A/C switch assembly | Refer to A/C Switch Assembly. |

| 12. | PTC heater relay 1 | The PTC relays control the flow of current to the PTC heater. The PTC relays are controlled by the BCM. |

| 13. | PTC heater relay 2 | |

| 14. | PTC heater relay 3 | |

| 15. | Intake door motor | Refer to Intake Door Motor. |

| 16. | Front blower motor | Refer to Front Blower Motor. |

| 17. | Mode door motor | Refer to Mode Door Motor. |

| 18. | Air mix door motor RH | Refer to Air Mix Door Motor. |

| 19. | Intake sensor | Refer to Intake Sensor. |

| 20. | Air mix door motor | Refer to Air Mix Door Motor. |

| 21. | PTC heater | Refer to PTC Heater. |

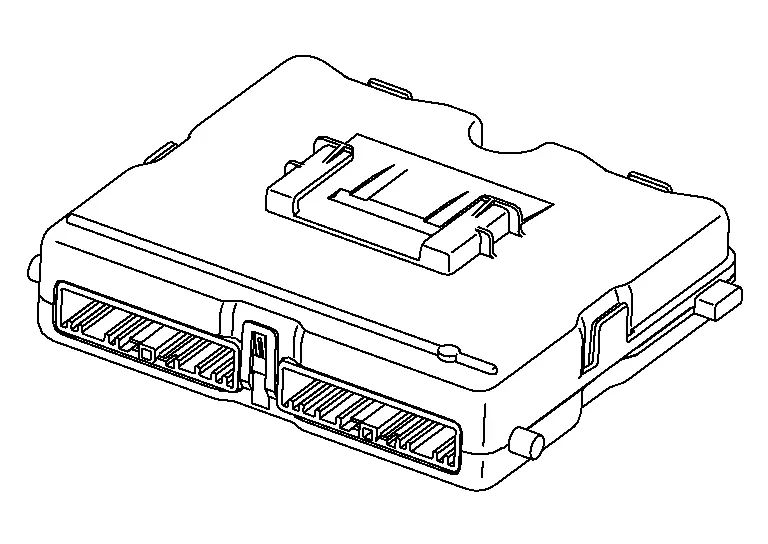

A/C Amp.

-

The A/C amp. is installed to the blower unit assembly. Refer to Component Parts Location.

-

A/C amp. controls the manual air conditioning system by inputting and calculating signals from each sensor and each switch.

-

The A/C amp. consists of a microcomputer and input/output connectors for signals and power supply.

-

It has a CAN communications function, and it transmits and receives the necessary signals from each control module via CAN communication.

-

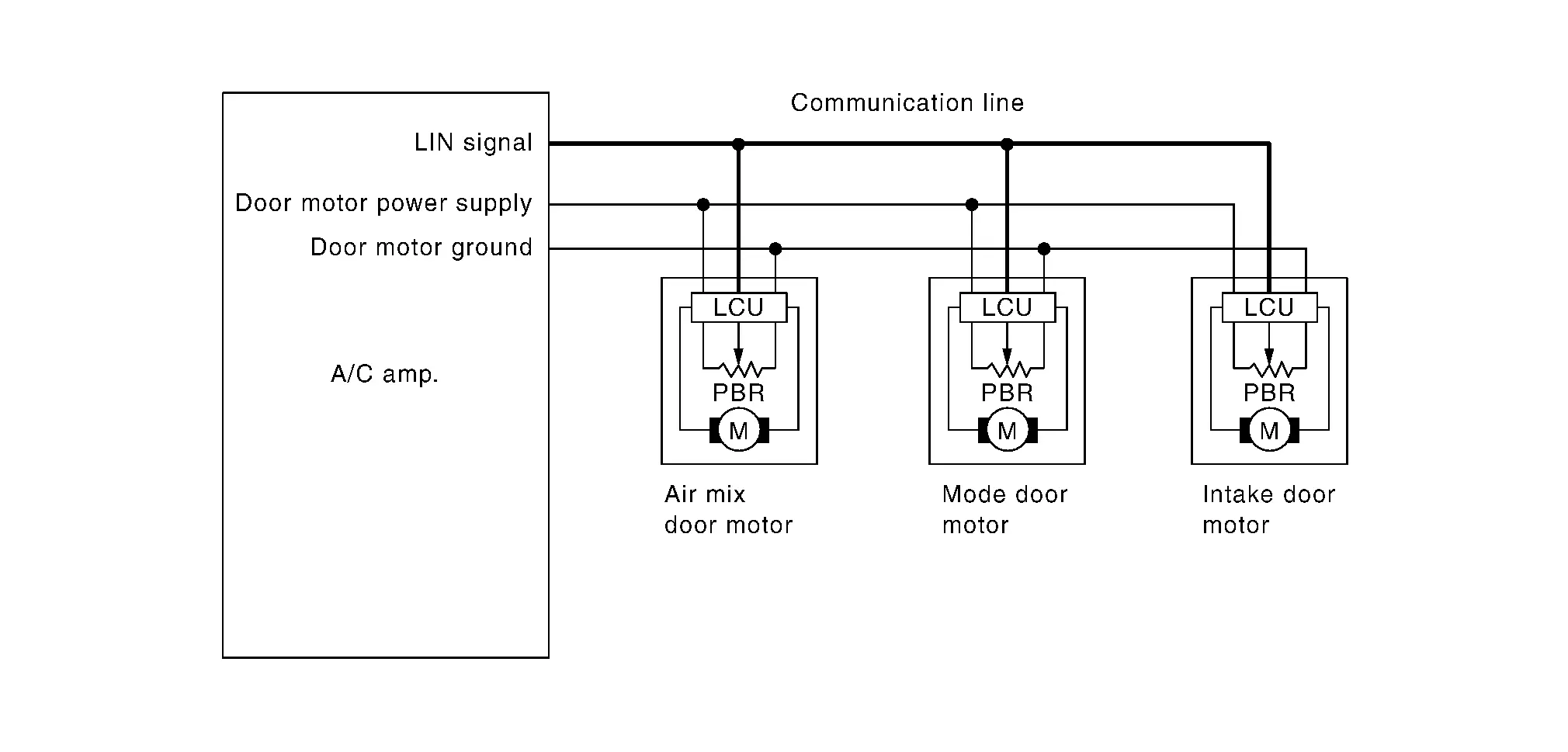

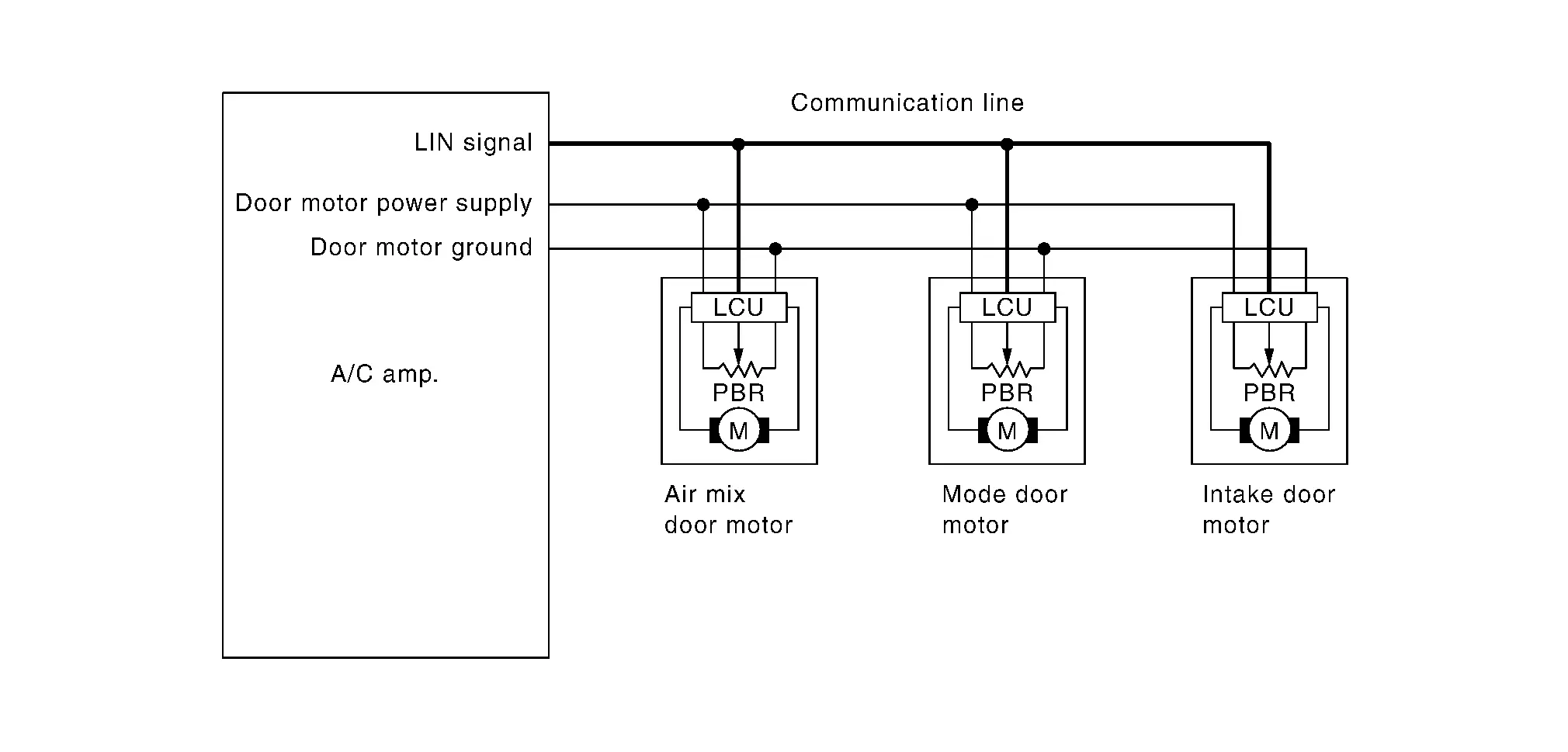

It has a LIN communications function, and transmits and receives signals to/from the A/C switch assembly and each door motor.

-

A/C amp. has self-diagnosis function. Diagnosis of manual air conditioning system can be performed quickly.

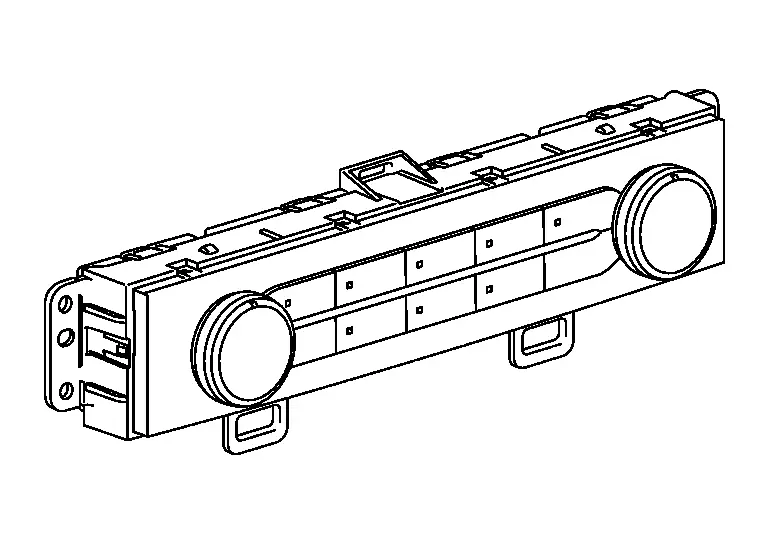

A/C Switch Assembly

-

The A/C switch assembly is installed to the center ventilator finisher. Refer to Component Parts Location.

-

A/C switch assembly has switches that can set and indicate the operation of manual air conditioning system by each control switch. It transmits setting status to A/C amp. via LIN communication line.

-

The operating status of the manual air conditioner is transmitted from the A/C amp. via LIN communication. A/C amp. controls manual air conditioning system.

COMPONENT OPERATION

-

The operation status of each switch is detected by the control and is transmitted as an operation signal to the A/C amp. via LIN communication.

-

The following switch specification control was adopted.

-

Temperature control : Dial type

-

Air outlet control : Push-return type

-

Air inlet control : Push-return type

-

Air flow control : Dial type

-

A/C compressor ON/OFF : Push-return type

NOTE:

NOTE:

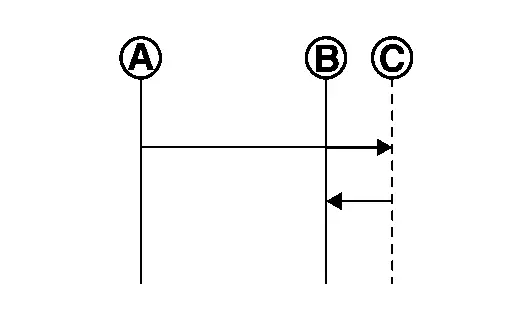

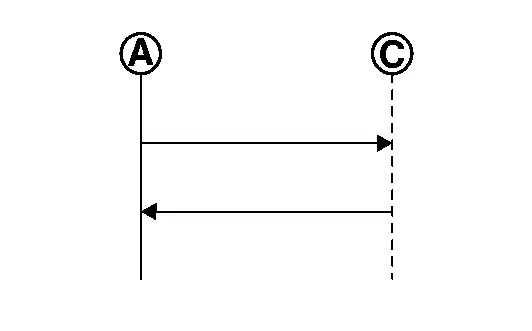

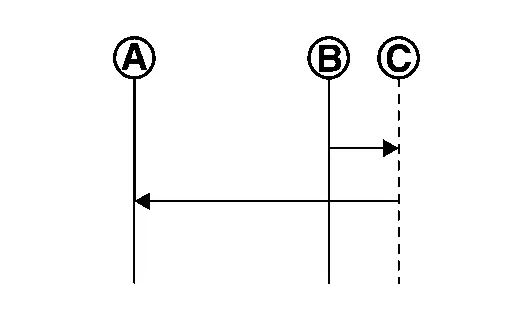

Regarding the push switches : Refer to the following for the differences between push-lock types and push-return types.

Operation Push-lock type Push-return type Switch ON operation

Switch OFF operation

Push-lock type

-

Switch ON operation: At the time of switch ON operation, the switch is pushed from the reference point

to the pushed position

to the pushed position  , and the switch turns ON. When the switch is released from this position, the switch returns from the pushed position

, and the switch turns ON. When the switch is released from this position, the switch returns from the pushed position  to the hold position

to the hold position  , and the switch position is held there.

, and the switch position is held there. -

Switch OFF operation: At the time of the switch OFF operation, the switch is pushed from the hold position

to the pushed position

to the pushed position  . When the switch is released from this position, the switch returns from the pushed position

. When the switch is released from this position, the switch returns from the pushed position  to the reference point

to the reference point  , and the switch turns OFF.

, and the switch turns OFF.

Push-return type

-

Switch ON operation: At the time of the switch ON operation, the switch is pushed from the reference point

to the pushed position

to the pushed position  , and the switch turns ON. When the switch is released from this position, the switch returns from the pushed position

, and the switch turns ON. When the switch is released from this position, the switch returns from the pushed position  to the reference point

to the reference point  .

. -

Switch OFF operation: At the time of the switch OFF operation, the switch is pushed from the reference point

to the pushed position

to the pushed position  , and the switch turns OFF. When the switch is released from this position, the switch returns from the pushed position

, and the switch turns OFF. When the switch is released from this position, the switch returns from the pushed position  to the reference point

to the reference point  .

.

-

-

-

For details the function of each switch. Refer to Switch Name and Function.

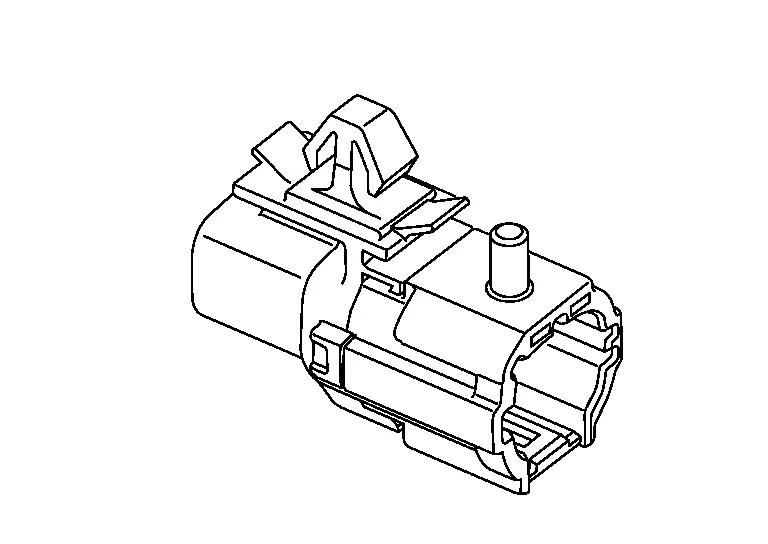

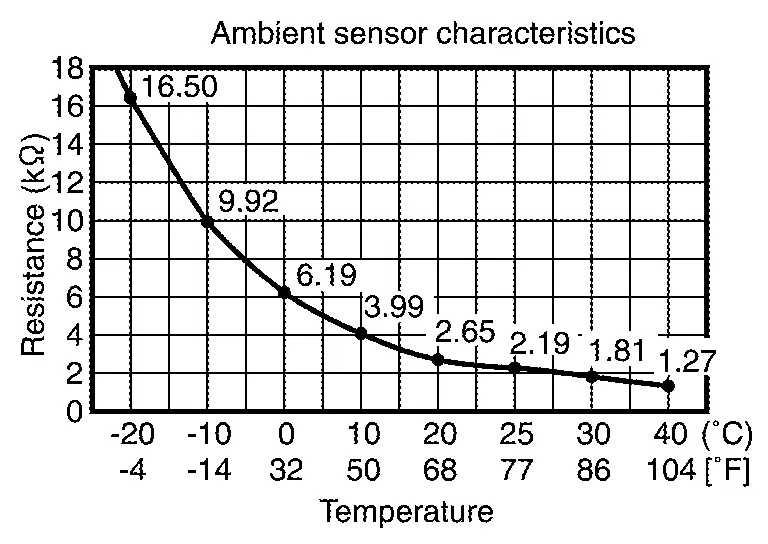

Ambient Sensor

-

The ambient sensor is installed to the active grille shutter. Refer to Component Parts Location.

-

The ambient sensor detects the temperature of the ambient air, and transmits the ambient sensor signal to the combination meter.

-

This signal is transmitted from the combination meter to the A/C amp. via CAN communication and is used in air conditioning system.

COMPONENT OPERATION

The ambient sensor measures the ambient air temperature, and transmits the ambient sensor signal to the combination meter. This sensor uses a thermistor with electrical resistance that decreases as the temperature increases.

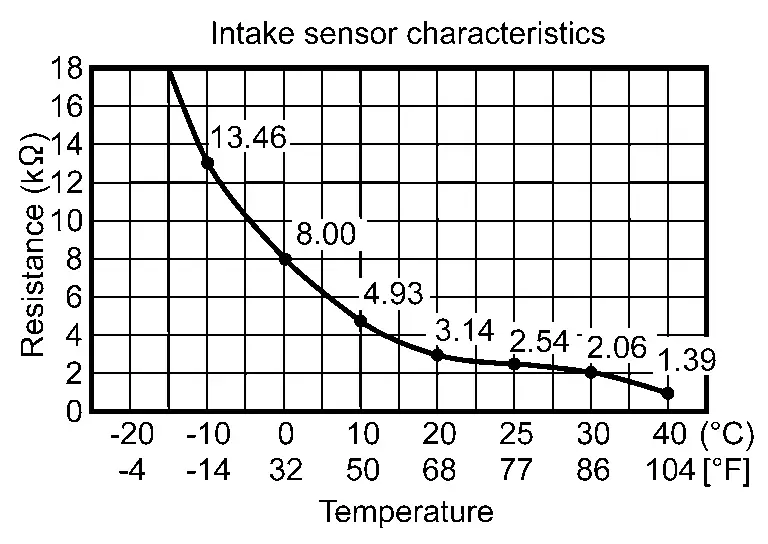

Intake Sensor

The intake sensor converts the evaporator surface temperature detected with thermistor into the voltage, and the A/C amp. inputs this voltage.

-

Intake sensor is located on the evaporator. Refer to Component Parts Location.

-

Intake sensor measures evaporator temperature (through air temperature).

-

The sensor uses a thermistor which is sensitive to the change in temperature. The electrical resistance of the thermistor decreases as temperature increases.

Refrigerant Pressure Sensor

-

The refrigerant pressure sensor is installed to the high pressure pipe. Refer to Component Parts Location.

-

The refrigerant pressure sensor converts high-pressure side refrigerant pressure into voltage and outputs it to ECM.

-

This value is transmitted from the ECM to the A/C amp. via CAN communication and is used in A/C compressor control and cooling fan operation request control.

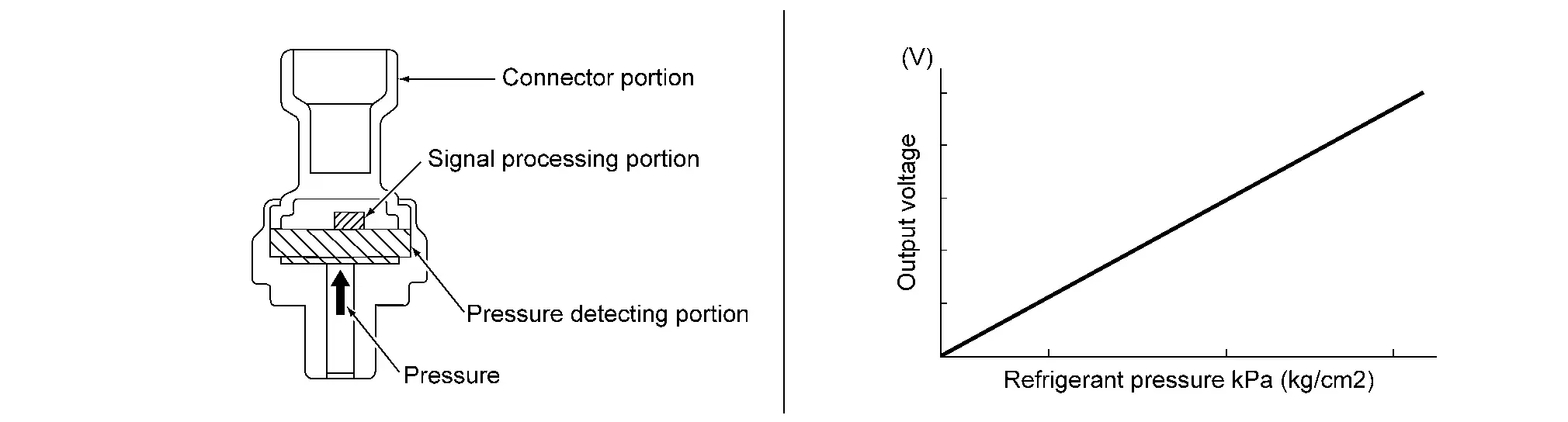

COMPONENT OPERATION

-

The refrigerant pressure sensor is a capacitance type sensor. It consists of a pressure detection area and a signal processing area.

-

The pressure detection area, which is a variable capacity condenser, changes internal static capacitance according to pressure force.

-

The signal processing area detects the static capacitance of the pressure detection area, converts the static capacitance into a voltage value, and transmits the voltage value to ECM.

-

The output voltage increases as the refrigerant pressure rises.

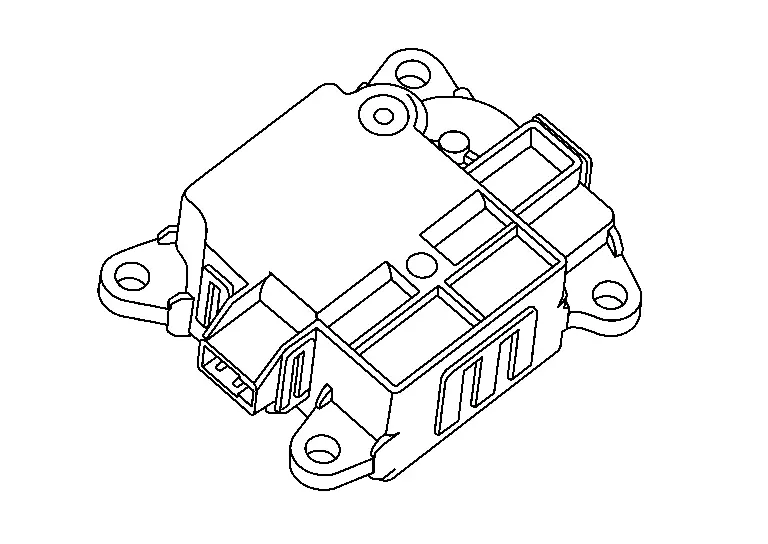

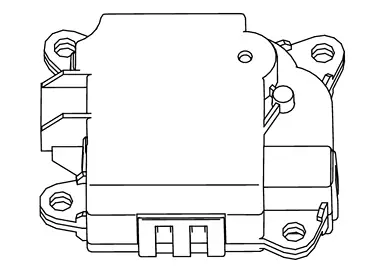

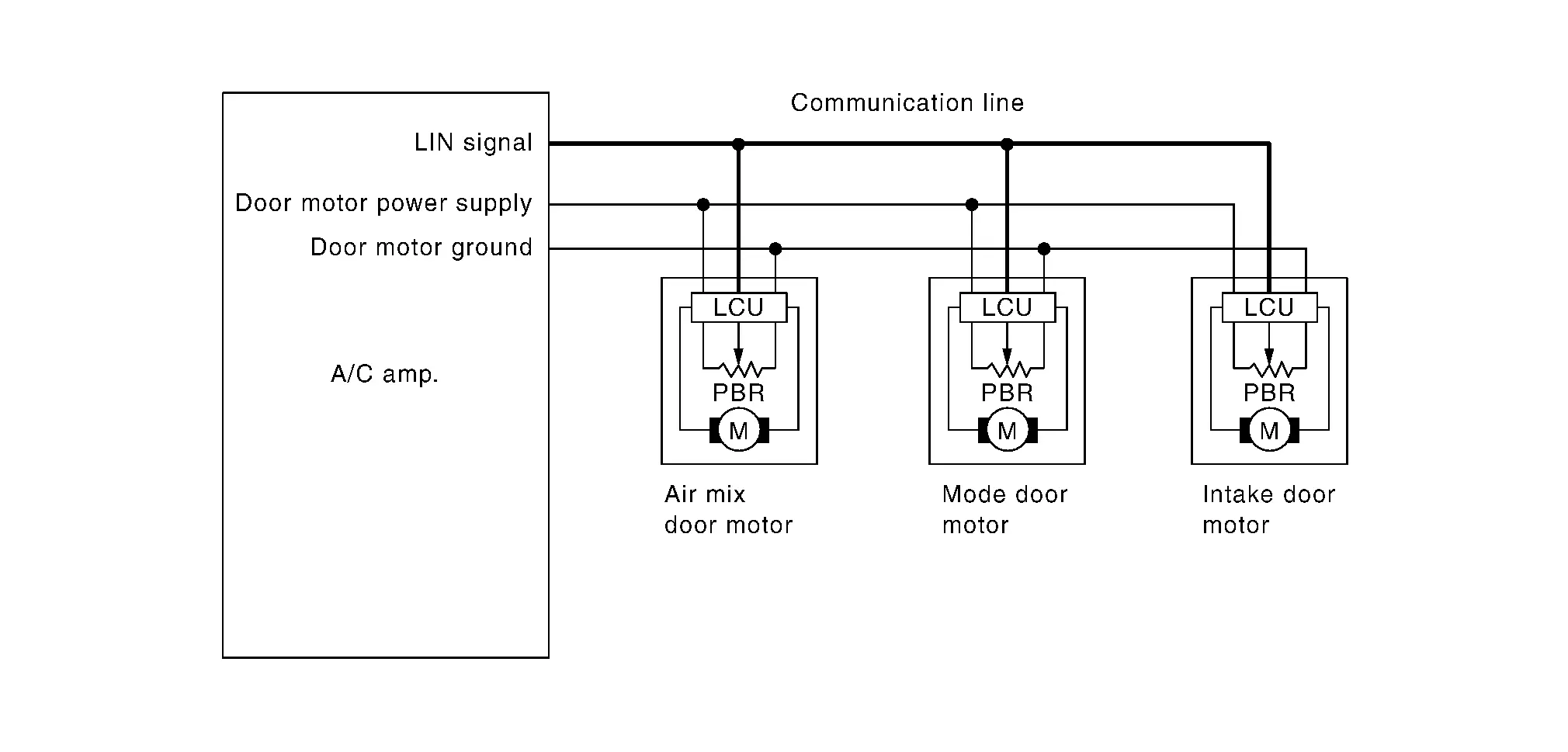

Air Mix Door Motor

-

The air mix door motor is installed to the heater & cooling unit assembly. Refer to Component Parts Location.

-

Air mix door motor consists of motor that drives door, PBR (Potentio Balance Register) that detects door position and LCU (Local Control Unit) that perform multiplex communication control (LIN) with A/C amp.

-

Rotation of motor is transmitted to air mix door. Air flow temperature is switched.

COMPONENT OPERATION

-

LCU (Local Control Unit) is built into air mix door motor. And detects door position by PBR (Potentio Balance Resistor).

-

A/C amp. communicates with each LCU via communication line. And receives air mix door position feedback signal from LCU.

-

LCU transmits the signal of door movement completion to A/C amp., when the door movement is completed.

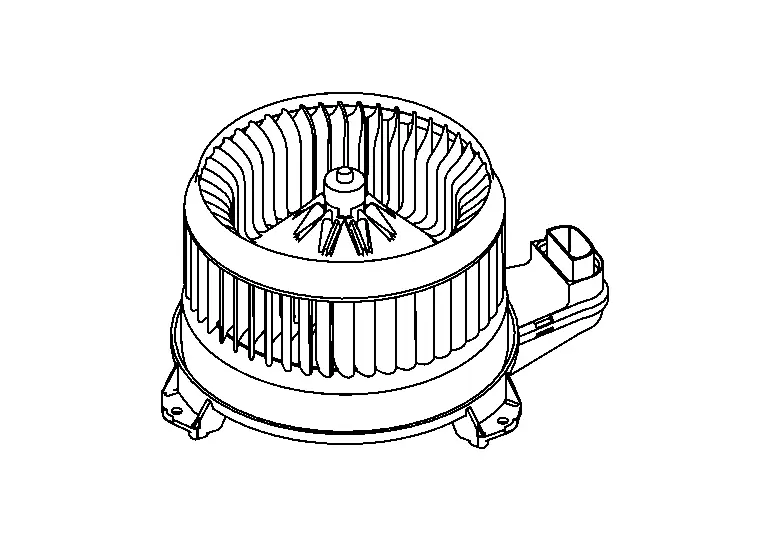

Front Blower Motor

-

The front blower motor is installed to the blower unit assembly. Refer to Component Parts Location.

-

The motor with the sirocco fan rotates, taking in-Nissan Ariya vehicle or ambient air and sending it into the passenger room.

-

The rotation speed is changed according to the voltage controlled by the A/C amp. and the air flow rate is controlled.

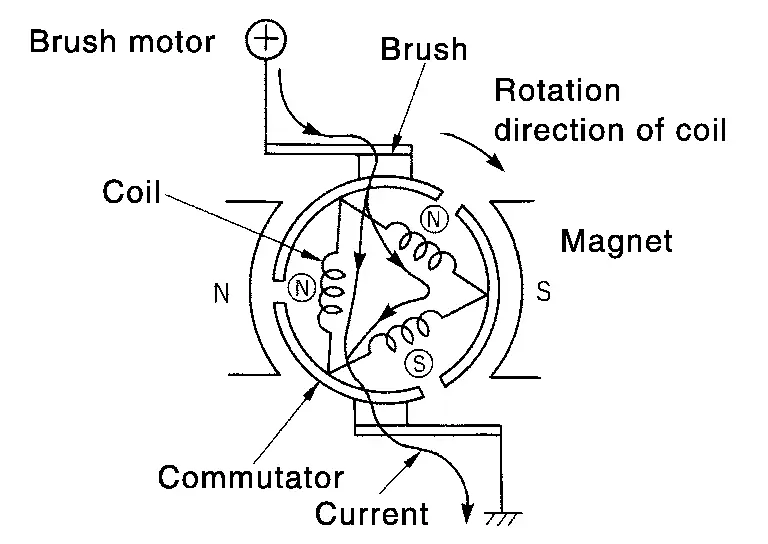

COMPONENT OPERATION

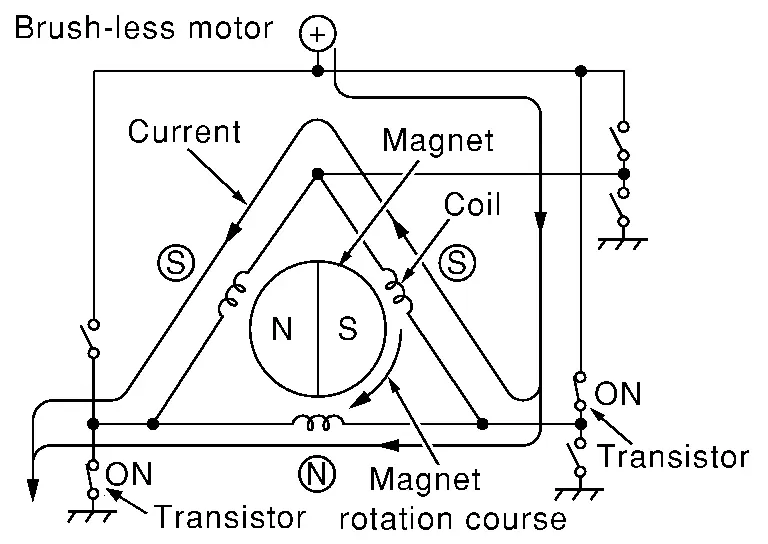

The front blower motor adopts the brush-less.

NOTE:

NOTE:

-

Brush motor rotates the coil while the brush functions as contact point.

-

Brush-less motor, the magnet part rotates.

Intake Door Motor

-

The intake door motor is installed to the blower unit assembly. Refer to Component Parts Location.

-

Intake door motor consists of motor that drives door, PBR (Potentio Balance Register) that detects door position and LCU (Local Control Unit) that perform multiplex communication control (LIN) with A/C amp.

-

Rotation of motor is transmitted to intake door. Air inlet is switched.

COMPONENT OPERATION

-

LCU (Local Control Unit) is built into intake door motor. And detects door position by PBR (Potentio Balance Resistor).

-

A/C amp. communicates with each LCU via communication line. And receives intake door position feedback signal from LCU.

-

LCU transmits the signal of door movement completion to A/C amp., when the door movement is completed.

Mode Door Motor

-

The mode door motor is installed to the heater & cooling unit assembly. Refer to Component Parts Location.

-

Mode door motor consists of motor that drives door, PBR (Potentio Balance Register) that detects door position and LCU (Local Control Unit) that perform multiplex communication control (LIN) with A/C amp.

-

Rotation of motor is transmitted to each mode door. Air outlet is switched.

COMPONENT OPERATION

-

LCU (Local Control Unit) is built into mode door motor. And detects door position by PBR (Potentio Balance Resistor).

-

A/C amp. communicates with each LCU via communication line. And receives each mode door position feedback signal from LCU.

-

LCU transmits the signal of door movement completion to A/C amp., when the door movement is completed.

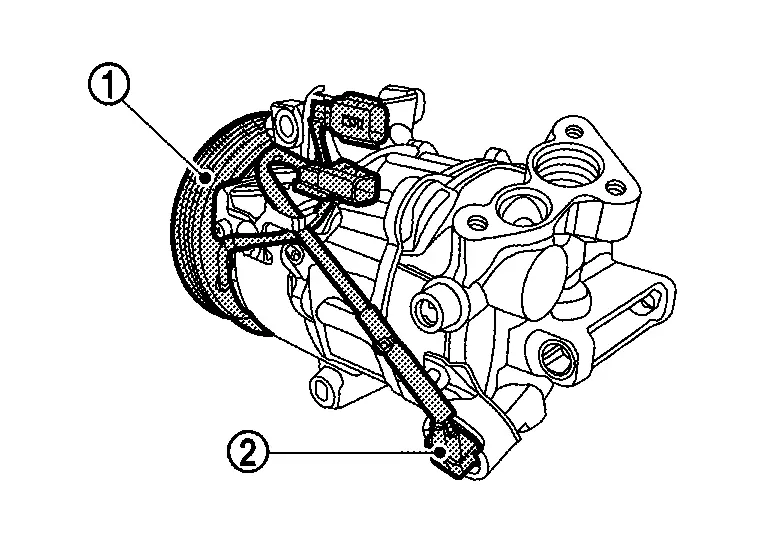

A/C Compressor

-

The A/C compressor is installed to the engine. Refer to Component Parts Location.

-

For controlling the A/C compressor, a magnetic clutch

that drives the A/C compressor is used, together with an ECV

that drives the A/C compressor is used, together with an ECV  that changes the refrigerant discharge amount.

that changes the refrigerant discharge amount.

-

The magnetic clutch turns ON/OFF, transmitting the rotational motion of the engine to the A/C compressor.

-

Changing the cam plate angle, it changes the piston stroke and controls the refrigerant discharge amount.

-

IPDM E/R controls the magnetic clutch and ECV (electrical control valve) according to the requests from the A/C amp. and ECM, and changes the A/C compressor drive and refrigerant discharge amount.

COMPONENT OPERATION

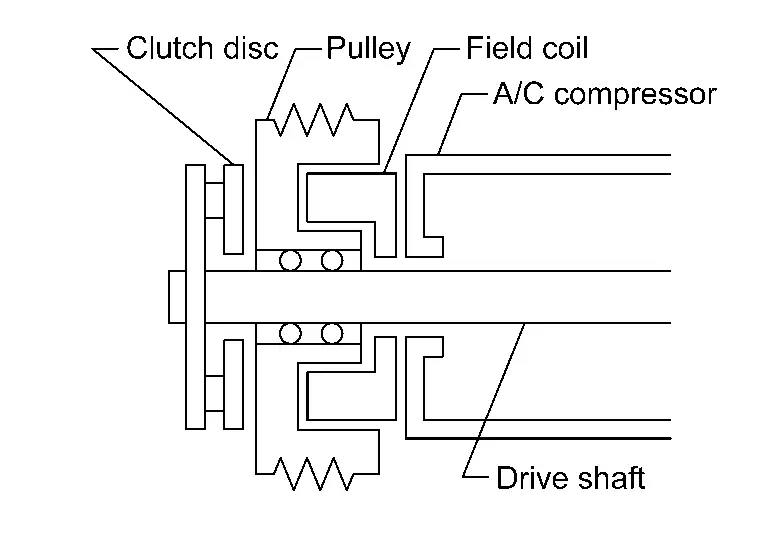

Magnetic Clutch

-

Magnetic clutch consists of pulley, clutch disc, and field coil.

-

Pulley is connected with crankshaft pulley of engine via drive belt and is always rotated while engine is running.

-

Clutch disc is connected with drive shaft of A/C compressor.

-

Field coil, which becomes a strong electric magnet when electricity is supplied, strongly pulls clutch disc and presses it to pulley.

-

-

When Smart FET integrated in IPDM E/R turns ON, electricity is supplied to field coil, clutch disc is presses to pulley, and engine rotational movement is transmitted from crankshaft pulley тЗТ drive belt тЗТ pulley тЗТ clutch disc тЗТ drive shaft. A/C compressor is operated. When Smart FET turns OFF, electricity is not supplied to field coil, and clutch disc is released from pulley. A/C compressor is not operated.

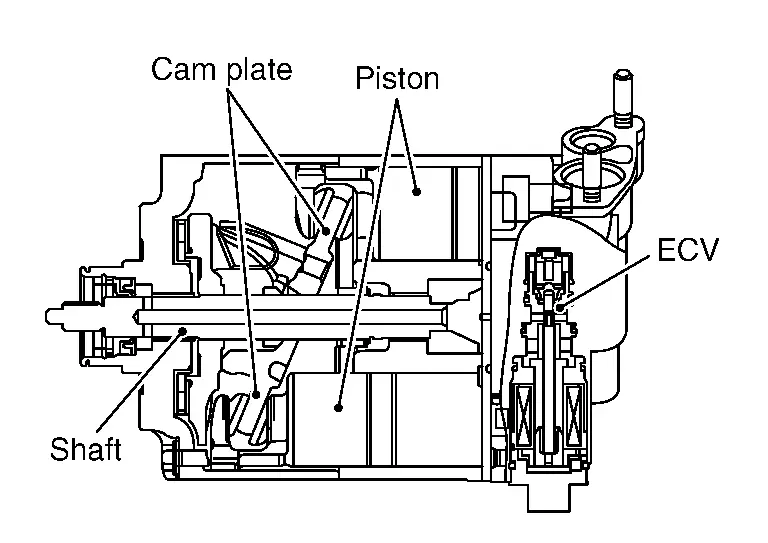

ECV (Electrical Control Valve)

-

ECV (Electrical Control Valve) is integrated in the A/C compressor. IPDM E/R receives the ECV control signal from A/C amp. via CAN communication, and ECV is controlled according to the control signal transmitted from IPDM E/R.

-

ECV is controlled according to the control signal transmitted from IPDM E/R.

The control signal transmitted by IPDM E/R is controlled according to the ECV control signal transmitted from A/C amp. via CAN communication.

-

ECV varies the refrigerant pressure balance in the left and right refrigerant spaces that are divided by the cam plate in order to change the angle of the cam plate inside the A/C compressor.

By changing the cam plate angle, it changes the piston stroke and controls the refrigerant discharge amount.

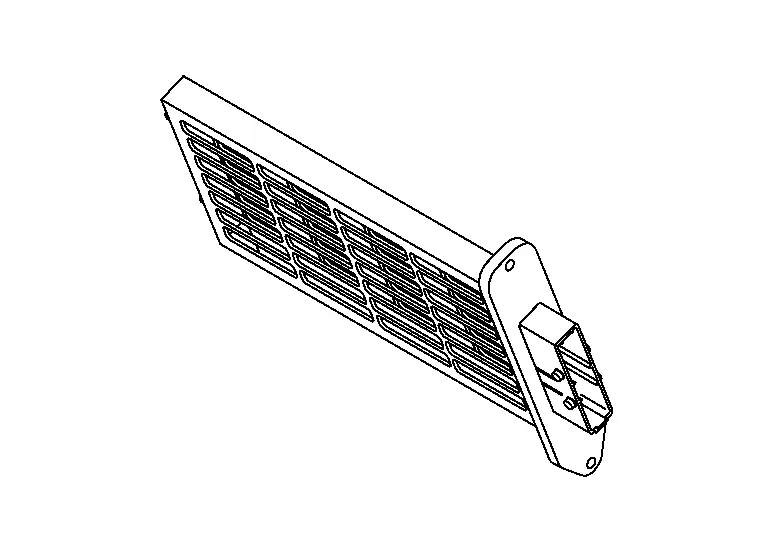

PTC Heater

-

The PTC heater is installed to the heater & cooling unit assembly. Refer to Component Parts Location.

-

Heat element is heated and air flow temperature is increased by power supply from BCM controlled PTC heater relay.

COMPONENT OPERATION

The PTC heater utilizes a PTC element is adopted.

NOTE:

NOTE:

The PTC  thermistor

generates heat in response to current flow. The temperature (and

resistance) of the thermistor element varies with current flow.

Excessive current flow will cause the element's temperature to rise.

When the temperature reaches a specified level, the electrical

resistance will rise sharply to control the circuit current.

thermistor

generates heat in response to current flow. The temperature (and

resistance) of the thermistor element varies with current flow.

Excessive current flow will cause the element's temperature to rise.

When the temperature reaches a specified level, the electrical

resistance will rise sharply to control the circuit current.

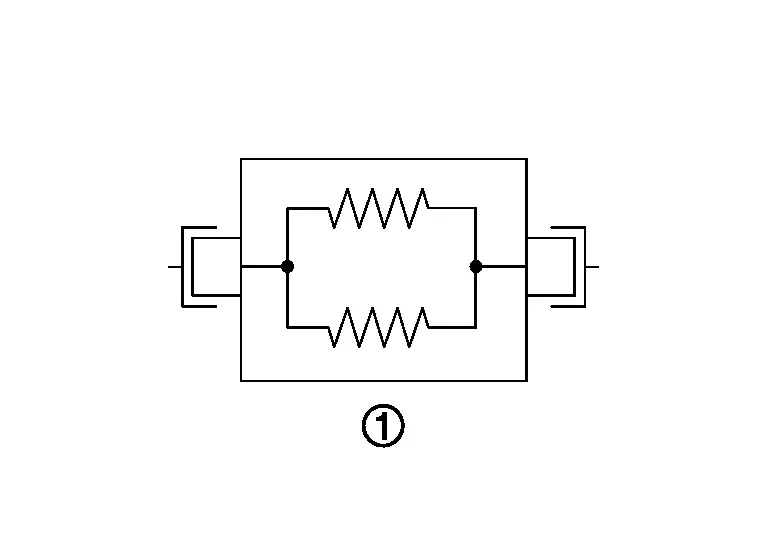

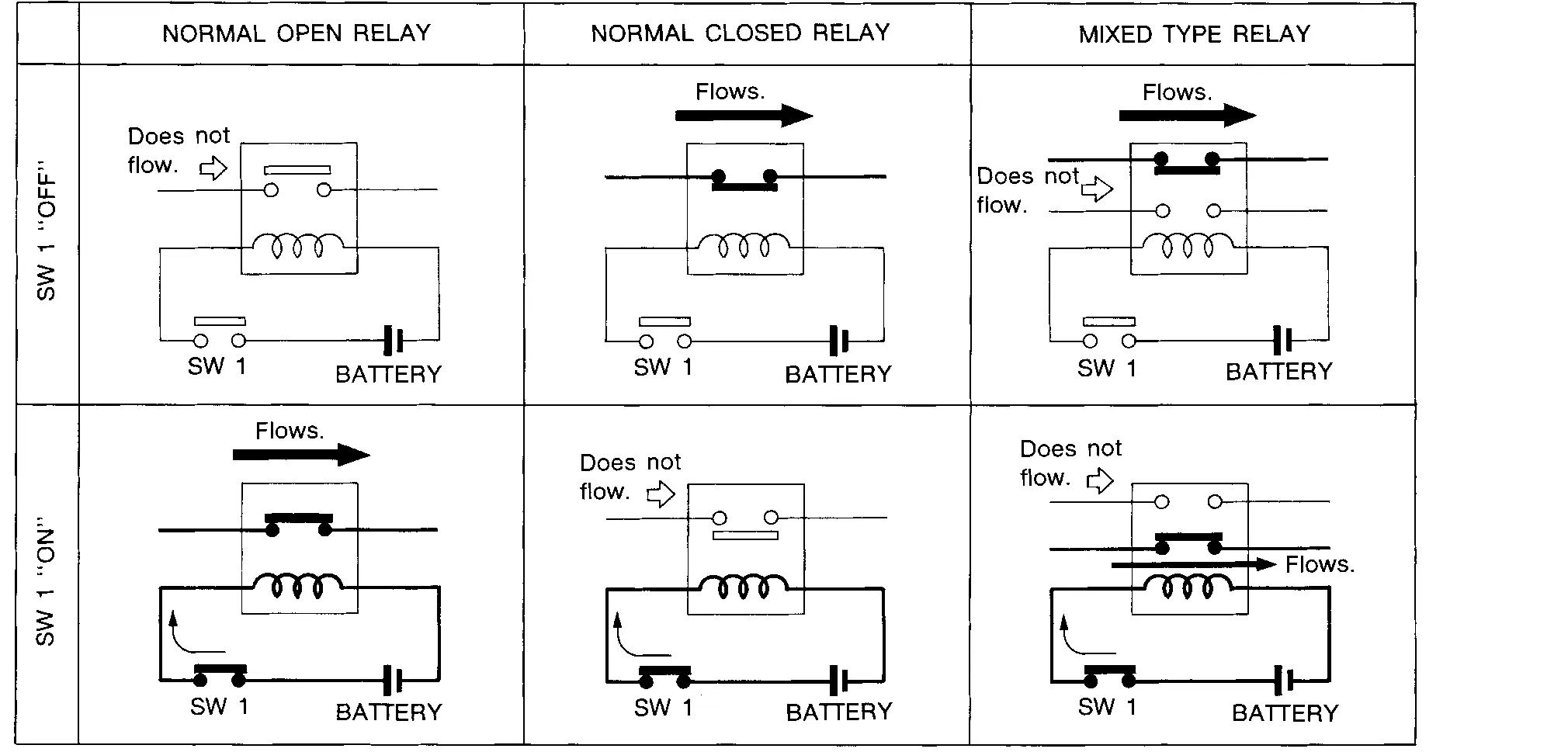

PTC Heater Relay

-

The PTC heater relay is installed in the relay box on the behind of the front bumper. Refer to Component Parts Location.

-

This relay activates according to the PTC heater relay control signal that is controlled by BCM, and activates the PTC heater.

-

It turns the relay switch ON/OFF and sends a large current from the battery to the PTC heater.

COMPONENT OPERATION

-

The PTC heater relay utilizes multiple relays. It decides the PTC heater ON/OFF and the power supplied to the heating wires according to the ON/OFF combination of these relays.

-

The PTC heater relay utilizes a normal open relay.

Other materials:

Lib 12v Branch Line Circuit

Diagnosis Procedure

CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the following terminals and connectors for damage, bend and loose connection (unit side and connector side).

12V sub battery (lithium ion battery)

...

Service Data and Specifications (sds)

Battery

Type L3-EFB

20 hour rate capacity

[VтАВтАУтАВAh]

12тАВтАУтАВ70

Cold cranking current (For reference value)

[A]

720

CAUTION:

It is mandatory to always use a battery designed for the

stop/start system. Failure to do this causes early deterioration or

system malf ...

Emergency Call (SOS) button

Emergency support

Basic information

NissanConnect Services provide a range of emergency assistance features designed to support the driver of the Nissan Rogue in critical situations.

For example, in the event of a medical emergency or serious injury, pressing the in-vehicle Emergency Call (SOS) b ...