Nissan Rogue Service Manual: C1164, C1165 CV system

DTC Logic

DTC Logic

| DTC | Display Item | Malfunction detected condition | Possible causes |

| C1164 | CV 1 | When a malfunction is detected in cut valve 1. |

|

| C1165 | CV 2 | When a malfunction is detected in cut valve 2. |

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT.

With CONSULT.

- Turn ignition switch ON.

- Perform self-diagnostic result.

Is DTC “C1164” or “C1165” detected? YES >> Proceed to diagnosis procedure. Refer to BRC-102, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to BRC-57, "Wiring Diagram".

1.CONNECTOR INSPECTION

- Turn ignition switch OFF.

- Disconnect ABS actuator and electric unit (control unit) connectors.

- Check connectors and terminals for deformation, disconnection, looseness or damage.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace as necessary.

2.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) BATTERY POWER SUPPLY

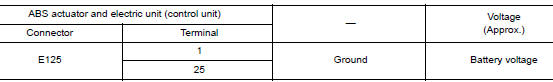

Check voltage between ABS actuator and electric unit (control unit) connector E125 terminals 1, 25 and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace malfunctioning components.

3.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) GROUND CIRCUIT

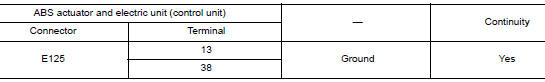

Check continuity between ABS actuator and electric unit (control unit) connector E125 terminals 13, 38 and ground.

Is the inspection result normal? YES >> Replace ABS actuator and electric unit (control unit). Refer to BRC-136, "Removal and Installation".

NO >> Repair or replace malfunctioning components.

C1160 DECEL G SEN SET

C1160 DECEL G SEN SET

DTC Logic

DTC DETECTION LOGIC

DTC

Display Item

Malfunction detected condition

Possible causes

C1160

DECEL G SEN SET

When calibration of yaw rate/side/decel G sensor is ...

C1170 variant coding

C1170 variant coding

DTC Logic

DTC DETECTION LOGIC

DTC

Display Item

Malfunction detected condition

Possible causes

C1170

VARIANT CODING

When the information in ABS actuator and electric

...

Other materials:

Driver side door mirror defogger

Description

Heats the heating wire with the power supply from the rear window defogger

relay to prevent the door mirror

from fogging up.

Component Function Check

1. CHECK DOOR MIRROR DEFOGGER LH

Check that heating wire of door mirror defogger LH is heated when turning the

rear window defogg ...

Parking brake shoe

Exploded View

Back plate

Parking brake shoe

Brake strut

Return spring

Spring

Return spring to brake strut

Adjuster

Toggle lever

Anti-rattle pin

: Apply PBC (Poly Butyl

Cuprysil) grease or silicone-based grease

Removal and Installation

REMOVAL

WARNING ...

P1572 brake pedal position switch

DTC Description

DTC DETECTION LOGIC

NOTE:

This self-diagnosis has the one trip detection logic. When malfunction A is

detected, DTC is not stored

in ECM memory. And in that case, 1st trip DTC and 1st trip freeze frame data are

displayed. 1st trip

DTC is erased when ignition switch OFF. And ...