Nissan Rogue Service Manual: Brake booster

Inspection

Operation

Depress the brake pedal several times at five second intervals with the engine stopped. Start the engine with the brake pedal fully depressed. Check that the clearance between brake pedal and dash lower panel decreases.

NOTE: A slight impact with a small click may be felt on the pedal when the brake pedal is fully depressed. This is normal brake system operation.

Vacuum Inspection

Idle the engine for one minute to apply vacuum to the brake booster.

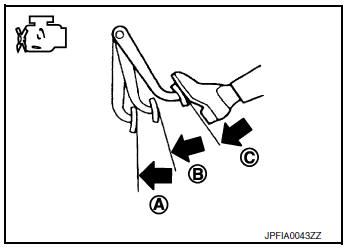

Stop the engine. Depress the brake pedal several times at five second intervals until the accumulated vacuum is released to atmospheric pressure. Check that the clearance between brake pedal and dash lower panel gradually increases (A → B → C) each time the brake pedal is depressed during this operation.

Depress the brake pedal with the engine running. Then stop the engine while holding down the brake pedal. Check that the brake pedal stroke does not change after holding down the brake pedal for 30 seconds or more.

NOTE: A slight impact with a small click may be felt on the pedal when the brake pedal is fully depressed. This is normal brake system operation.

Brake master cylinder

Brake master cylinder

Inspection

Check for brake fluid leakage at the following areas:

Master cylinder mounting face

Reservoir tank mounting face

Brake tube and brake tube connections

Bra ...

Front disc brake

Front disc brake

BRAKE PAD

BRAKE PAD : Inspection

Check brake pad wear thickness from an inspection hole (A) on cylinder

body. Check using a scale if necessary.

Wear thickness : Refer to BR-55, "Front Dis ...

Other materials:

Moving Object Detection (MOD) (if so equipped)

The MOD system can inform the driver of moving

objects behind the vehicle when backing out of

garages, maneuvering in parking lots and in other

such instances.

The MOD system detects moving objects by

using image processing technology on the image

shown in the display.

The MOD system oper ...

Daytime running light system

The daytime running lights automatically illuminate

when the engine is started with the parking

brake released. The daytime running lights operate

with the headlight switch in the OFF position

or in the position. Turn the

headlight switch

to the position for full

illumination when

drivin ...

Warning/indicator lights

Warning

light

Name

Anti-lock Braking

System (ABS) warning

light

Brake warning light

Charge warning

light

Low tire pressure

warning light

Low windshield

washer fluid warning

light

Master w ...