Nissan Rogue (T33) 2021-Present Service Manual: Awd :: Precaution. Precautions

Precautions

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of collisions.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” sections of this Service Manual.

WARNING:

Always observe the following items for preventing accidental activation:

-

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in the event of a collision that would result in air bag inflation, it is recommended that all maintenance and repair be performed by an authorized NISSAN/INFINITI dealer.

-

Improper repair, including incorrect removal and installation of the SRS, can lead to personal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag Module, see “SRS AIR BAG”.

-

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

Always observe the following items for preventing accidental activation:

-

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition/power switch ON or engine running, never use air or electric power tools or strike near the sensor(s) with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing serious injury.

-

When using air or electric power tools or hammers, always switch the ignition/power switch OFF, disconnect the 12V battery or batteries, and wait at least 3 minutes before performing any service.

Precautions for Removing Battery Terminal

-

With the adoption of Auto ACC function, ACC power is automatically supplied by operating the Intelligent Key or remote keyless entry or by opening/closing the driver side door. In addition, ACC power is supplied even after the ignition switch is in the OFF position, i.e. ACC power is supplied for a certain fixed time.

-

When disconnecting the 12V battery terminal, place the ignition switch in the OFF position before disconnecting the 12V battery terminal, observing “How to disconnect 12V battery terminal” described below.

NOTE:

NOTE:

Some ECUs operate for a certain fixed time even after ignition switch is in the OFF position and ignition power supply is stopped. If the battery terminal is disconnected before ECU stops, accidental DTC detection or ECU data damage may occur.

-

For Nissan Ariya vehicles with the 2-batteries, be sure to connect the main battery and the sub battery before placing the ignition switch in the ON position.

NOTE:

NOTE:

If the ignition switch is in the ON position with any one of the terminals of main battery and sub battery disconnected, then DTC may be detected.

-

After installing the 12V battery, always check "Self Diagnosis Result" of all ECUs and erase DTC.

NOTE:

NOTE:

The removal of 12V battery may cause a DTC detection error.

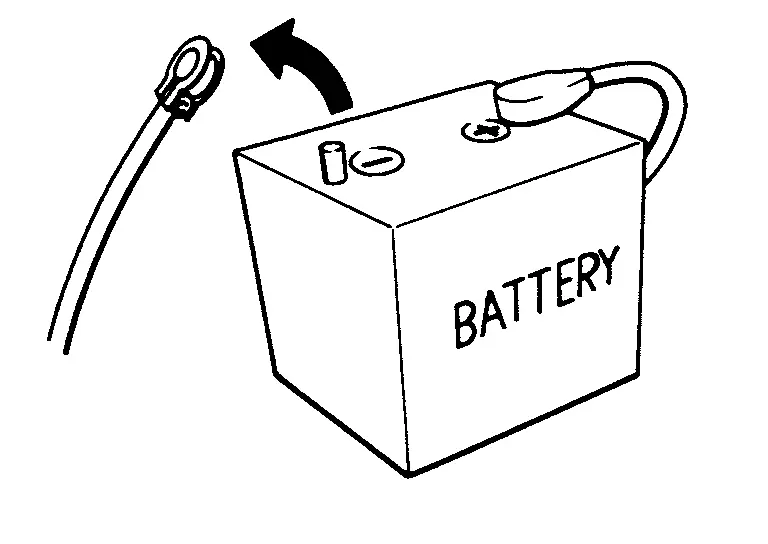

HOW TO DISCONNECT 12V BATTERY TERMINAL

Disconnect 12V battery terminal according to instruction described below.

-

Open the hood.

-

Place the ignition switch in the ON position.

-

Place the ignition switch in the OFF position with the driver side door opened.

-

Get out of the Nissan Ariya vehicle and close the driver side door.

-

Wait at least 3 minutes.

CAUTION:

While waiting, never operate the Nissan Ariya vehicle such as locking, opening, and closing doors. Violation of this caution results in the activation of ACC power supply according to the Auto ACC function.

-

Remove 12V battery terminal.

CAUTION:

After installing 12V battery, always check self-diagnosis results of all ECUs and erase DTC.

Precautions for Drive Shaft

CAUTION:

Note the following precautions when disassembling and assembling drive shaft.

-

Joint sub-assembly does not disassemble because it is non-overhaul parts.

-

Perform work in a dust-free location.

-

Before disassembling and assembling, clean the parts.

-

Prevent the entry of foreign objects during disassembly of the service location.

-

Disassembled parts must be carefully reassembled in the correct order. If work is interrupted, a clean cover must be placed over parts.

-

Paper shop cloths must be used. Fabric shop cloths must not be used because of the danger of lint adhering to parts.

-

Disassembled parts (except for rubber parts) should be cleaned with kerosene which shall be removed by blowing with air or wiping with paper shop cloths.

Other materials:

P00d2 Ho2s2 Heater

DTC Description

DTC DETECTION LOGIC DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P00D2

00

Heated O2 sensor heater B1 sensor 2

(HO2S heater control circuit range/performance bank 1 sensor 2)

Diagnosis condition

—

Signal (terminal)

...

B20a4-87 Headlamp (lh) Lin Communication

DTC Description

DTC DETECTION LOGIC DTC No.

CONSULT screen items

(Trouble diagnosis content) DTC detection condition

B20A4–87

Headlamp (LH) LIN communication

[Headlamp (left hand) local interconnect network communication]

[MISSING MESSAGE]

Diagnosis condition

Ignition switch ...

Preparation

Special Service Tools

The actual shapes of TechMate tools may differ from those of special service tools illustrated here.

Tool number

(TechMate No.)

Tool name Description

(NI-39570)

Chassis ear

Locates the noise

(NI-50397)

Squeak and Rattle Kit

Repairs the cause o ...