Nissan Rogue Service Manual: Removal and installation

GENERATOR

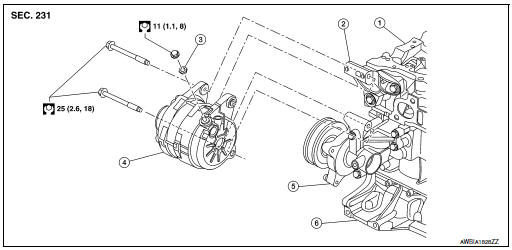

Exploded View

REMOVAL

- Cylinder head

- Generator bracket

- Washer

- Generator

- Water pump

- Cylinder block

Removal and Installation

REMOVAL

- Disconnect negative terminal from battery. Refer to PG-75, "Exploded View".

- Remove wheel and tire (RH) using a power tool. Refer to WT-60, "Removal and Installation".

- Remove fender protector side cover. Refer to EXT-28, "FENDER PROTECTOR : Exploded View"

- Remove front air spoiler. Refer to EXT-16, "Exploded View".

- Remove engine under cover. Refer to EXT-37, "ENGINE UNDER COVER : Removal and Installation".

- Remove drive belt. Refer to EM-13, "Removal and Installation".

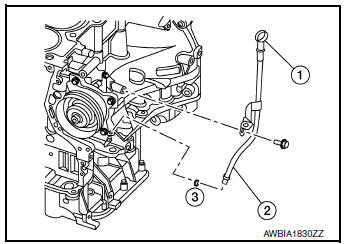

- Remove oil level gauge (1).

- Remove oil level gauge guide (2).

- Remove oil level gauge guide O-ring (3).

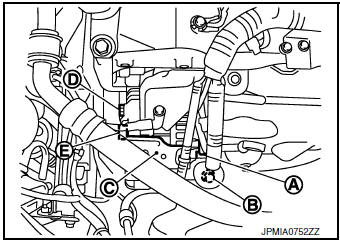

- Disconnect generator connector (A).

- Remove “B” terminal nut (B) and “B” terminal harness.

- Remove harness bracket (C).

NOTE: Harness ground does not have to be removed during bracket removal.

- Remove upper generator mounting bolt (D), using suitable tool.

- Remove lower generator mounting bolt (E), using suitable tool.

- Remove generator upward from the vehicle.

INSTALLATION

Installation is in the reverse order of removal.

- Tighten oil level gauge guide bolt to specification.

Oil level gauge guide bolt : 21.6 N·m (2.2 kg-m, 16 ft-lb)

CAUTION:

- Be careful to tighten “B” terminal nut carefully.

- Install generator and check tension of belt. Refer to EM-13, "Checking".

- Do not reuse oil level gauge guide O-ring.

- Prior to installation, apply clean engine oil to oil level gauge guide O-ring.

- Ensure O-ring sealing surface is free from dust or imprefections.

- Allow engine to run for 5 minutes and inspect for engine oil leaks.

Inspection

GENERATOR PULLEY INSPECTION

Perform the following.

- Make sure that the generator pulley does not bind or rattle.

- Make sure that the generator pulley is tight. Refer to CHG-20, "Exploded View".

Symptom diagnosis

Symptom diagnosis

CHARGING SYSTEM

Symptom Table

...

Service data and specifications (SDS)

Service data and specifications (SDS)

Generator

...

Other materials:

EVAP control system pressure sensor

Exploded View

EVAP control system pressure sensor

O-ring

EVAP canister

EVAP canister vent control valve

EVAP canister vent control valve hose

EVAP vent line

EVAP canister purge hose

Clamp

Front

Removal and Installation

NOTE:

The EVAP canister syst ...

Preparation

Special Service Tool

The actual shapes of tools may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name

Description

—

(J-46534)

Trim Tool Set

Removing trim components

Commercial Service Tool

(TechMate No.)

Tool n ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

...