Nissan Rogue Service Manual: P0524 engine oil pressure

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| P0524 | ENGINE OIL PRESSURE (Engine oil pressure too low) | An EOP sensor signal voltage applied to ECM remains lower than the specified value continuously for 10 seconds or more when the engine speed is 1,000 rpm or more. |

POSSIBLE CAUSE

- Decrease in engine oil pressure

- Decrease in engine oil level

- Engine oil condition

- EOP sensor

- Engine body

FAIL-SAFE

- ECM illuminates oil pressure warning lamp on the combination meter.

- Engine speed will not rise more than 4,000rpm due to the fuel cut.

- Fail-safe is canceled when ignition switch OFF → ON.

DTC CONFIRMATION PROCEDURE

CAUTION: If “EC-362, "Diagnosis Procedure"” is unfinished, be sure to perform Step 3 and 4.

1.PRECONDITIONING-1

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TEST CONDITION: Before performing the following procedure, confirm that battery voltage is 11 V or more at idle.

>> GO TO 2.

2.PRECONDITIONING-2

Is “Diagnosis Procedure” of DTC P0524 finished? YES >> GO TO 3.

NO >> GO TO 4.

3.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and warm it up to normal operating temperature.

- Maintain the following conditions for about 10 consecutive seconds.

| Selector lever | P or N position |

| Engine coolant temperature | 70°C (158°F) or more |

| Engine speed | 1,000 rpm or more |

NOTE: With engine speed set around 4,000 rpm, the phenomenon can be reproduced more easily.

3. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-362, "Diagnosis Procedure".

NO >> INSPECTION END

4.CHECK ENGINE OIL LEVEL

Check engine oil pressure. Refer to LU-7, "Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Proceed to EC-362, "Diagnosis Procedure".

5.CHECK ENGINE OIL PRESSURE

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “DATA MONITOR” mode of “ENGINE” using CONSULT.

- Start the engine and check that “EOP SENSOR” changes, according to engine speeds.

| Monitor item | Condition | Value (Approx.) | |

| EOP SENSOR |

|

Engine speed: Idle | 1,450 mV or more |

| Engine speed: 2,000 rpm | 2,850 mV or more | ||

Without CONSULT

Without CONSULT

Check engine oil level. Refer to LU-7, "Inspection".

Is the inspection result normal? YES >> GO TO 3.

NO >> Proceed to EC-362, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK ENGINE OIL LEVEL

- Turn ignition switch OFF.

- Check engine oil pressure level. Refer to LU-7, "Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 4.

2.CHECK ENGINE OIL PRESSURE

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “DATA MONITOR” mode of “ENGINE” using CONSULT.

- Start the engine and check that “EOP SENSOR” changes, according to engine speeds.

| Monitor item | Condition | Value (Approx.) | |

| EOP SENSOR |

|

Engine speed: Idl | 1,450 mV or more |

| Engine speed: 2,000 rpm | 2,850 mV or more | ||

Without CONSULT

Without CONSULT

Check engine oil pressure. Refer to LU-7, "Inspection".

Is the inspection result normal? YES >> GO TO 3.

NO >> Check oil pump. Refer to LU-15, "Inspection".

3.CHECK EOP SENSOR

Check EOP sensor. Refer to EC-360, "Component Inspection".

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

4.CHECK ENGINE OIL LEAKAGE

Check engine oil leakage. Refer to LU-6, "Engine Lubrication System Schematic".

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

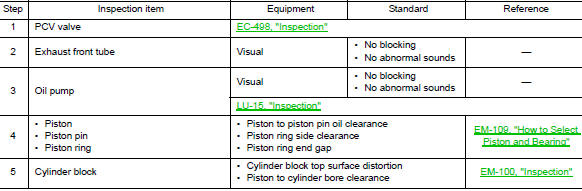

5.CHECK CAUSE OF ENGINE OIL CONSUMPTION

Check the following item.

>> Repair or replace error-detected parts.

6.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> INSPECTION END

Component Inspection

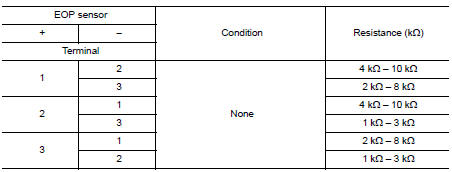

1.CHECK EOP SENSOR

- Turn ignition switch OFF.

- Disconnect EOP sensor harness connector.

- Check resistance between EOP sensor connector terminals.

Is the inspection result normal? YES >> INSPECTION END.

NO >> Replace EOP sensor. Refer to EC-14, "Component Parts Location".

P0520 EOP sensor

P0520 EOP sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0520

EOP SENSOR/SWITCH

(Engine oil pressure senso ...

P052A, P052B intake valve timing control

P052A, P052B intake valve timing control

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P052A

CAMSHAFT POSITION TIMING B1

(Cold start “A ...

Other materials:

Rear bumper

Exploded View

Rear bumper fascia side bracket

(LH)

Rear mud protector

Rear bumper reinforcement support

(LH)

Rear bumper fascia undercover

(LH)

Rear bumper reinforcement

Rear energy absorber

Rear bumper bracket (LH)

Rear bumper fascia

Rear bumper fascia re ...

Wheel sensor

FRONT WHEEL SENSOR

FRONT WHEEL SENSOR : Exploded View

Front LH wheel sensor

Harness connector

Slant line

FRONT WHEEL SENSOR : Removal and Installation

CAUTION:

Be careful not to damage front wheel sensor edge and sensor

rotor teeth.

When removing the front ...

LDW system operation

LDW system operation

The LDW system operates above approximately

45 MPH (70 km/h).

When the vehicle approaches either the left or

the right of the traveling lane, the LDW system

will chime a sound and the LDW light on the

instrument panel will blink to alert the driver

The LDW system is ...