Nissan Rogue Service Manual: P0451 EVAP control system pressure sensor

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| P0451 | EVAP SYS PRES SEN (Evaporative emission system pressure sensor/switch range/performance) | ECM detects a sloshing signal from the EVAP control system pressure sensor |

POSSIBLE CAUSE

- Harness or connectors (EVAP control system pressure sensor circuit is shorted.)

- EVAP control system pressure sensor

FAIL-SAFE

Not applicable

DTC CONFIRMATION PROCEDURE

NOTE: Never remove fuel filler cap during DTC confirmation procedure.

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

With CONSULT>>GO TO 2.

With CONSULT>>GO TO 2.

Without CONSULT>>GO TO 5.

Without CONSULT>>GO TO 5.

2.PERFORM DTC CONFIRMATION PROCEDURE-1

With CONSULT

With CONSULT

- Start engine and let it idle for least 40 seconds.

NOTE: Do not depress accelerator pedal even slightly.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-328, "Diagnosis Procedure".

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE-2

With CONSULT

With CONSULT

- Select “EVAP DIAG READY” in “DATA MONITOR” mode of “ENGINE”.

- Let it idle until “OFF” of “EVAP DIAG READY” changes to “ON”.

NOTE: It will take at most 2 hours until “OFF” of “EVAP DIAG READY” changes to “ON”.

- Turn ignition switch OFF and wait at least 90 minutes.

NOTE: Never turn ignition switch ON during 90 minutes.

- Turn ignition switch ON.

- Select “EVAP LEAK DIAG” in “DATA MONITOR” mode of “ENGINE”.

- Check that “EVAP LEAK DIAG” indication.

Which is displayed on CONSULT? CMPLT>> GO TO 4.

YET >> 1. Perform DTC CONFIRMATION PROCEDURE again.

2. GO TO 1.

4.PERFORM DTC CONFIRMATION PROCEDURE-3

With CONSULT

With CONSULT

Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-328, "Diagnosis Procedure".

NO >> INSPECTION END

5.PERFORM DTC CONFIRMATION PROCEDURE-4

With GST

With GST

- Start engine and let it idle for least 40 seconds.

NOTE: Do not depress accelerator pedal even slightly.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-328, "Diagnosis Procedure".

NO >> GO TO 6.

6.PERFORM DTC CONFIRMATION PROCEDURE-5

With GST

With GST

- Let it idle for at least 2 hours.

- Turn ignition switch OFF and wait at least 90 minutes.

NOTE: Never turn ignition switch ON during 90 minutes.

- Turn ignition switch ON.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-328, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR FOR WATER

- Turn ignition switch OFF.

- Disconnect EVAP control system pressure sensor harness connector.

- Check sensor harness connector for water.

Water should not exist.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace harness connector.

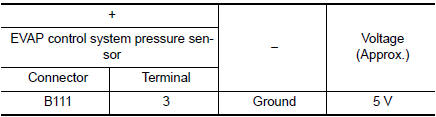

2.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR POWER SUPPLY

- Turn ignition switch ON.

- Check the voltage between EVAP control system pressure sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

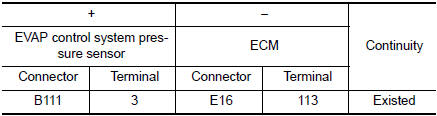

3.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between EVAP control system pressure sensor harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts

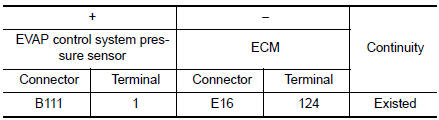

4.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between EVAP control system pressure sensor harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

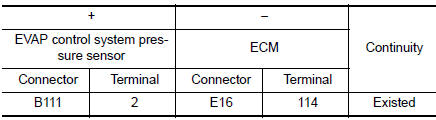

5.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR SIGNAL CIRCUIT

- Check the continuity between EVAP control system pressure sensor harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

6.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

Check the EVAP control system pressure sensor. Refer to EC-330, "Component Inspection".

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace EVAP control system pressure sensor. Refer to FL-22, "Removal and Installation".

7.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> INSPECTION END

Component Inspection

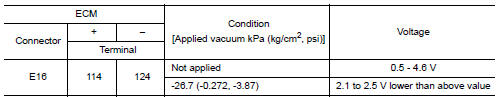

1.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

- Turn ignition switch OFF.

- Remove EVAP control system pressure sensor with its harness

connector connected from EVAP canister.

Always replace O-ring with a new one.

- Install a vacuum pump to EVAP control system pressure sensor.

- Turn ignition switch ON and check output voltage between ECM harness connector and ground under the following conditions.

CAUTION:

- Always calibrate the vacuum pump gauge when using it.

- Do not apply below -93.3 kPa (-0.952 kg/cm2, -13.53 psi) or pressure over 101.3 kPa (1.033 kg/ cm2, 14.69 psi).

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace EVAP control system pressure sensor. Refer to FL-22, "Removal and Installation".

P0448 EVAP canister vent control valve

P0448 EVAP canister vent control valve

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0448

VENT CONTROL VALVE

(Evaporative emission sys ...

P0452 EVAP control system pressure sensor

P0452 EVAP control system pressure sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0452

EVAP SYS PRES SEN

(Evaporative emission syst ...

Other materials:

Towing load/specification

TOWING LOAD/SPECIFICATION CHART

U.S. and Canada

Maximum Towing Capacity*1

1,100lb.

(500 kg)

Maximum Tongue Load

110 lb.

(50 kg)

Maximum Gross Combined Weight Rating

5,291 lb.

(2,400 kg)

*1: The towing capacity ...

System

CVT CONTROL SYSTEM

CVT CONTROL SYSTEM : System Description

SYSTEM DIAGRAM

MAIN CONTROL CONTENTS OF TCM

Controls

Reference

Line pressure control

TM-36, "LINE PRESSURE CONTROL : System Description"

Shift control

TM-37, "SHIFT CONTROL : System De ...

Door mirror glass

Removal and Installation

REMOVAL

Release the metal clips and pawls that retain the door mirror

glass using a suitable tool, disconnect the harness connectors

(A) (if equipped) from the door mirror glass and remove.

Metal clip

: Pawl

INSTALLATION

Installation is in the rever ...