Nissan Rogue Service Manual: P0340 CMP sensor (phase)

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting cond |

| P0340 | CMP SEN/CIRC-B1 (Camshaft position sensor ″A″ circuit bank 1 or single sensor) |

|

POSSIBLE CAUSE

- Harness or connectors (Camshaft position sensor circuit is open or shorted.)

- Camshaft position sensor

- Camshaft (Intake)

- Starter motor

- Starting system circuit

- Dead (Weak) battery

- Sensor power supply 2 circuit

FAIL-SAFE

Not applicable

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION: Before performing the following procedure, confirm that battery voltage is more than 10.5 V with ignition switch ON.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE-1

- Start engine and let it idle for at least 5 seconds.

If engine does not start, crank engine for at least 2 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-298, "Diagnosis Procedure".

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE-2

- Maintaining engine speed at more than 800 rpm for at least 5 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-298, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK STARTING SYSTEM

Turn ignition switch to START position.

Does the engine turn over? Does the starter motor operate?

YES >> GO TO 2.

NO >> Check starting system (Refer to STR-11, "Work Flow (With GR8-1200 NI)" or STR-15, "Work Flow (Without GR8-1200 NI)").

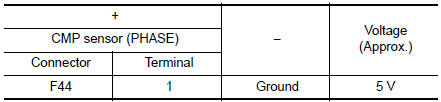

2.CHECK CAMSHAFT POSITION (CMP) SENSOR (PHASE) POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect camshaft position (CMP) sensor (PHASE) harness connector.

- Turn ignition switch ON.

- Check the voltage between CMP sensor (PHASE) harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK SENSOR POWER SUPPLY 2 CIRCUIT

Perform EC-484, "Diagnosis Procedure".

Is inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

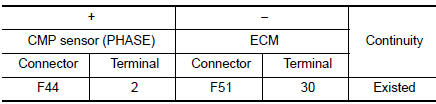

4.CHECK CMP SENSOR (PHASE) GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between CMP sensor (PHASE) harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

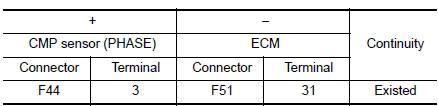

5.CHECK CMP SENSOR (PHASE) INPUT SIGNAL CIRCUIT

- Disconnect ECM harness connector.

- Check the continuity between CMP sensor (PHASE) harness connector and ECM harness connector

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

6.CHECK CAMSHAFT POSITION SENSOR (PHASE)

Check the camshaft position sensor (PHASE). Refer to EC-300, "Component Inspection (Camshaft position sensor)".

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace camshaft position sensor (PHASE). Refer to EM-64, "Removal and Installation".

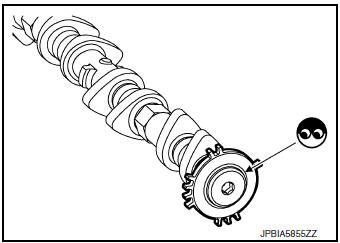

7.CHECK CAMSHAFT (INT)

Check the following.

- Accumulation of debris to the signal plate of camshaft rear end

- Chipping signal plate of camshaft rear end

Is the inspection result normal? YES >> GO TO 8.

NO >> Remove debris and clean the signal plate of camshaft rear end or replace camshaft. Refer to EM-64, "Removal and Installation".

8.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> INSPECTION END

Component Inspection (Camshaft position sensor)

1.CHECK CAMSHAFT POSITION SENSOR (PHASE)-1

- Turn ignition switch OFF.

- Loosen the fixing bolt of the sensor.

- Disconnect camshaft position sensor (PHASE) harness connector.

- Remove the sensor.

- Visually check the sensor for chipping.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace camshaft position sensor (PHASE).

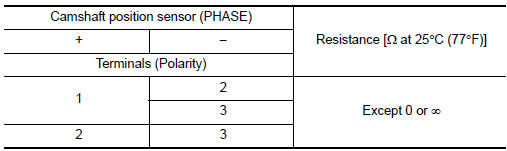

2.CHECK CAMSHAFT POSITION SENSOR (PHASE)-2

Check the resistance camshaft position sensor (PHASE) terminals as per the following.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace camshaft position sensor (PHASE). Refer to EM-64, "Removal and Installation".

P0335 CKP sensor (POS)

P0335 CKP sensor (POS)

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting conditio

P0335

CKP SEN/CIRCUIT

(Crankshaft position sensor & ...

P0420 three way catalyst function

P0420 three way catalyst function

DTC Description

DTC DETECTION LOGIC

The ECM monitors the switching frequency ratio of air fuel ratio (A/F)

sensor 1 and heated oxygen sensor 2.

A three way catalyst (manifold) with high oxygen s ...

Other materials:

Steering wheel

Exploded View

Steering wheel

Removal and Installation

REMOVAL

Set the front wheels and tires in the straight-ahead position.

Remove driver air bag module. Refer to SR-12, "Removal and

Installation"

Remove steering wheel bolt.

Disconnect harn ...

Fuel tank

FWD

FWD : Exploded View

Fuel filler cap

Grommet

Fuel filler tube

Cover

Clamp

Fuel filler hose

Clamp

Vent hose

Fuel tank protector

Fuel tank strap (LH)

Fuel tank strap (RH)

Fuel tank

T ...

P0604 ECM

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0604

ECM

[Internal control module random access

memory (RAM) error]

Malfunction in the internal RAM of ECM.

POSSIBLE CAUSE

ECM

FAIL-SAF ...