Nissan Rogue Service Manual: P0182, P0183 FTT sensor

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| P0182 | FTT SEN/CIRCUIT (Fuel temperature sensor ″A″ circuit low) | An excessively low voltage from the sensor is sent to ECM. |

| P0183 | FTT SEN/CIRCUIT (Fuel temperature sensor ″A″ circuit high) | An excessively high voltage from the sensor is sent to ECM. |

POSSIBLE CAUSE

- Harness or connectors (The FTT sensor circuit is open or shorted.)

- Fuel tank temperature sensor

- Combination meter

FAIL-SAFE

Not applicable

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON and wait at least 5 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-274, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK DTC WITH COMBINATION METER

Refer to MWI-21, "CONSULT Function (METER/M&A)".

Is the inspection result normal? YES >> GO TO 2.

NO >> Proceed to MWI-62, "Component Function Check".

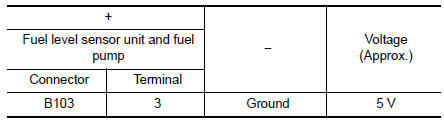

2.CHECK FUEL TANK TEMPERATURE (FTT) SENSOR POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect fuel level sensor unit and fuel pump harness connector.

- Turn ignition switch ON.

- Check the voltage between fuel level sensor unit and fuel pump harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

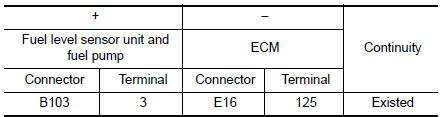

3.CHECK FUEL TANK TEMPERATURE (FTT) SENSOR POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between fuel level sensor unit and fuel pump harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

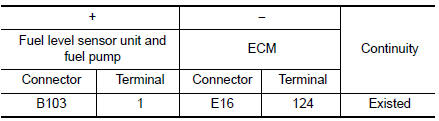

4.CHECK FUEL TANK TEMPERATURE (FTT) SENSOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM connector.

- Check the continuity between fuel level sensor unit and fuel pump harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK FUEL TANK TEMPERATURE (FTT) SENSOR

Check the FTT sensor. Refer to EC-276, "Component Inspection".

Is the inspection result normal? YES >> GO TO 6.

NO >> Replace “fuel level sensor unit and fuel pump”. Refer to FL-6, "Removal and Installation".

6.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> INSPECTION END

Component Inspection

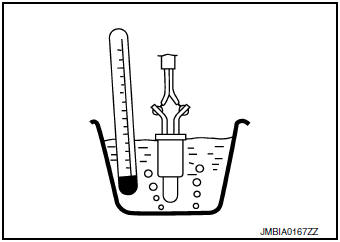

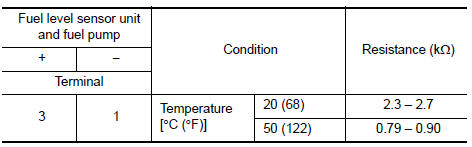

1.CHECK FUEL TANK TEMPERATURE (FTT) SENSOR

- Turn ignition switch OFF.

- Disconnect fuel level sensor unit and fuel pump harness connector.

- Remove fuel level sensor unit. Refer to FL-6, "Removal and Installation".

- Check resistance between fuel level sensor unit and fuel pump terminals by heating with hot water as shown in the figure.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace fuel level sensor unit and fuel pump. Refer to FL-6, "Removal and Installation".

P0181 FTT sensor

P0181 FTT sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0181

FTT SENSOR

(Fuel temperature sensor ″A ...

P0196 EOT sensor

P0196 EOT sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0196

EOT SENSOR

(Engine oil temperature sensor ra ...

Other materials:

P084c transmission fluid pressure SEN/SW H

DTC Description

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P084C

FLUID PRESS SEN/SW H

(Transmission Fluid Pressure Sensor/Switch H

Circuit Low)

When all of the following conditions are satisfied and this sta ...

P0014 EVT control

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0014

EXH/V TIM CONT-B1

(″B″ Camshaft position - timing over-advanced

or system performance bank 1)

There is a gap between angle of ...

Refrigerant pressure sensor

Component Function Check

1.CHECK REFRIGERANT PRESSURE SENSOR FUNCTION

Start engine and warm it up to normal operating temperature.

Turn A/C switch and blower fan switch ON.

Check the voltage between ECM harness connector terminals under

the following conditions.

...