Nissan Rogue Service Manual: How to check terminal

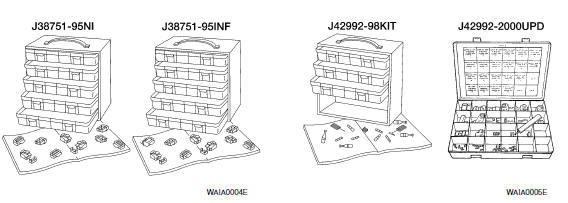

CONNECTOR AND TERMINAL PIN KIT

- Use the connector and terminal pin kits listed below when replacing connectors or terminals.

- The connector and terminal pin kits contain some of the most commonly used NISSAN/INFINITI connectors and terminals. For detailed connector and terminal pin replacement procedures, refer to the latest NISSAN/ INFINITI CONNECTOR AND TERMINAL PIN SERVICE MANUAL.

|

Tool number (Kent-Moore No.) Tool name |

Description |

| - (J38751-95NI) Connector and terminal pin kit (NISSAN) - (J38751-95INF) Connector and terminal pin kit (INFINITI) - (J42992-98KIT) OBD and terminal repair kit - (J42992-2000UPD) OBD-II Connector Kit Update |

|

HOW TO PROBE CONNECTORS

- Connector damage and an intermittent connection can result from improperly probing of the connector during circuit checks.

- The probe of a digital multimeter (DMM) may not correctly fit the connector cavity. To correctly probe the connector, follow the procedures below using a “T” pin. For the best contact grasp the “T” pin using an alligator clip.

Probing from Harness Side

Standard type (not waterproof type) connector should be probed from harness side with “T” pin.

- If the connector has a rear cover such as a ECM connector, remove the rear cover before probing the terminal.

- Do not probe waterproof connector from harness side. Damage to the seal between wire and connector may result.

Probing from Terminal Side

FEMALE TERMINAL

- There is a small notch above each female terminal. Probe each

terminal with the “T” pin through the notch.

Do not insert any object other than the same type male terminal into female terminal.

- Some connectors do not have a notch above each terminal. To probe each terminal, remove the connector retainer to make contact space for probing.

MALE TERMINAL

- Carefully probe the contact surface of each terminal using a “T” pin.

CAUTION: Dot not bend terminal.

How to Check Enlarged Contact Spring of Terminal

- An enlarged contact spring of a terminal may create intermittent signals in the circuit.

- If the intermittent open circuit occurs, follow the procedure below to inspect for open wires and enlarged contact spring of female terminal.

- Assemble a male terminal and approx. 10 cm (3.9 in) of wire.

NOTE: Use a male terminal which matches the female terminal.

- Disconnect the suspected faulty connector and hold it terminal side up.

- While holding the wire of the male terminal, try to insert the male terminal into the female terminal.

CAUTION: Do not force the male terminal into the female terminal with your hands.

- While moving the connector, check whether the male terminal can be easily inserted or not.

- If the male terminal can be easily inserted into the female terminal, replace the female terminal.

Waterproof Connector Inspection

If water enters the connector, it can short interior circuits. This may lead to intermittent problems.

Check the following items to maintain the original waterproof characteristics.

RUBBER SEAL INSPECTION

- Most waterproof connectors are provided with a rubber seal between the male and female connectors. If the seal is missing, the waterproof performance may not meet specifications.

- The rubber seal may come off when connectors are disconnected.

Whenever connectors are reconnected, make sure the rubber seal is properly installed on either side of male or female connector.

WIRE SEAL INSPECTION

- The wire seal must be installed on the wire insertion area of a waterproof connector. Be sure that the seal is installed properly.

Terminal Lock Inspection

Check for unlocked terminals by pulling wire at the end of connector.

An unlocked terminal may create intermittent signals in the circuit.

Basic inspection

Basic inspection

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Work flow

STEP

DESCRIPTION

STEP 1

Get detailed information about the conditions and the

environment when the incident occurred ...

Intermittent incident

Intermittent incident

DESCRIPTION

Sometimes the symptom is not present when the vehicle is brought in for

service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No ...

Other materials:

Car phone or CB radio

When installing a CB, ham radio or car phone in

your vehicle, be sure to observe the following

precautions; otherwise, the new equipment may

adversely affect the engine control system and

other electronic parts.

WARNING

A cellular phone should not be used for

any purpose wh ...

Cowl top

Exploded View

Cowl top side trim cover (RH)

Cowl top cover screen

Cowl top cover seal

EPT seal

Cowl top cover plug

Cowl top cover

Cowl top cover mask

Cowl top extension seal

Cowl top extension

Cowl top insulation

Cowl top side trim cover (LH)

Removal ...

System description

DESCRIPTION

Engine Lubrication System

Camshaft (INT)

Chain tensioner

Main gallery

Oil pan

Oil cooler

Balancer unit

Oil pan oil gallery

Oil filter (with relief valve)

Oil Strainer

Oil pump

Timing chain and balancer unit timing

chain ...