Nissan Rogue Service Manual: Fuel pressure

Work Procedure

FUEL PRESSURE RELEASE

1.FUEL PRESSURE RELEASE

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Perform “FUEL PRESSURE RELEASE” in “WORK SUPPORT” mode of “ENGINE” using CONSULT.

- Start engine.

- After engine stalls, crank it two or three times to release all fuel pressure.

- Turn ignition switch OFF.

Without CONSULT

Without CONSULT

- Remove fuel pump fuse located in IPDM E/R. For the fuse number, refer to EC-105, "Wiring Diagram". For the fuse arrangement, refer to PG-68, "IPDM E/R Terminal Arrangement".

- Start engine.

- After engine stalls, crank it two or three times to release all fuel pressure.

- Turn ignition switch OFF.

- Reinstall fuel pump fuse after servicing fuel system.

>> END

FUEL PRESSURE CHECK

CAUTION: Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger.

NOTE:

- Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel pressure cannot be completely released because this models do not have fuel return system.

- Use Fuel Pressure Gauge Kit [SST: (J-44321)] to check fuel pressure.

1.FUEL PRESSURE CHECK

- Release fuel pressure to zero.

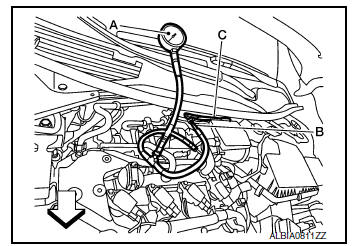

- Connect fuel tube adapter [SST:KV10120000] (B) to quick connector.

A : Fuel pressure gauge

C : Fuel feed hose

: Vehicle front

: Vehicle front

- Turn ignition switch ON and check for fuel leakage.

- Start engine and check for fuel leakage.

- Read the indication of fuel pressure gauge

At idling : Approximately 350 kPa (3.57 kg/cm2, 51 psi)

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK FUEL HOSES AND FUEL TUBES

Check fuel hoses and fuel tubes for clogging.

Is the inspection result normal? YES >> Replace “fuel filter and fuel pump assembly”. Refer to FL-6, "Removal and Installation".

NO >> Repair or replace error-detected parts.

Mixture ratio self-learning value clear

Mixture ratio self-learning value clear

Description

This describes how to erase the mixture ratio self-learning value. For the

actual procedure, follow the instructions

in “Diagnosis Procedure”.

Work Procedure

1.START

With CONSU ...

How to set srt code

How to set srt code

Description

OUTLINE

In order to set all SRTs, the self-diagnoses as in the “SRT ITEM” table must

have been performed at least

once. Each diagnosis may require actual driving for a long period ...

Other materials:

Periodic maintenance

FRONT WHEEL HUB AND KNUCKLE

Inspection

Move the wheel hub and bearing in an axial direction by hand to verify

that looseness of wheel hub and

bearing exists. If any looseness exists, replace the wheel hub and bearing.

Axial end play : Refer to FAX-32, "Wheel Bearing".

Rota ...

Component parts

Component Parts Location

Combination meter

Engine room right side

Engine room left side

No.

Component part

Description

1

Combination meter (Charge warning lamp)

The IC regulator warning function activates to illuminate the charge

warning

...

P2814 select solenoid

DTC Description

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P2814

SELECT SOLENOID

(Select solenoid)

When all of the following conditions are satisfied and this state is

maintained

for 0.48 seconds:

&n ...