Nissan Rogue Service Manual: CVT position

Inspection

- Turn ON the ignition switch with the shift selector at the “P” position.

- Press the shift selector button with the brake pedal depressed, and confirm that the shift selector can be moved to positions other than “P”. Also confirm that movement is not allowed from the “P” position to other position without depressing the brake pedal.

- Move the shift selector and check for “excessive effort”, “sticking”, “noise” or “rattle”.

- Confirm that shift selector stops at each position with the feel of engagement when it is moved through all the positions. Check whether or not the actual position the shift selector is in matches the position shown by the transaxle body.

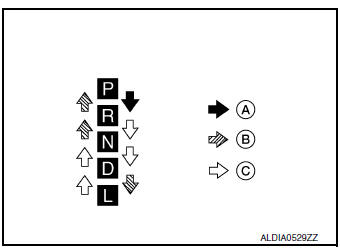

- Make sure that the shift selector is moved to all the shift positions in the manner shown.

- (A): Press shift selector button to operate shift selector, while depressing the brake pedal.

- (B): Press shift selector button to operate shift selector.

- (C): Shift selector can be operated without pressing the shift selector button.

- When the shift selector button is pressed without applying forward/ backward force to the shift selector at “P”, “R”, “N”, “D” or "L" positions, there should be no “sticking” on the shift selector button operation.

- Check that the back-up lamps do not illuminate when the shift selector is in the “P” position.

CAUTION: Check the lighting without pressing shift button.

- Check that the engine can be started with the shift selector in the “P” and “N” positions only.

- Check that the transaxle is locked completely when the shift selector is in the “P” position.

- The relationship between shift selector, engine starting ability, and shift position indicator lighting should satisfy the conditions of the following table.

| Shift selector position | Load direction to the shift selector | Applied load to the shift selector | Engine starting ability | Shift position indicator lighting |

| P | P (over stroke) ‚Üê P ‚Üí R | 29.4 N (3.00 kg, 6.61 lb) | Start | P indicator shall be illuminated |

| R | P ‚Üê R | Not start | R indicator shall be illuminated | |

| N | R ← N | — | N indicator shall be illuminated | |

| — | — | Start | ||

| D | — | — | Not start | D indicator shall be illuminated |

| L | — | — | Not start | L indicator shall be illuminated |

Adjustment

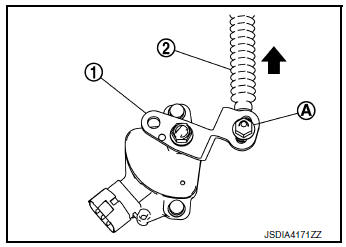

- Move the selector lever to the “P” position.

CAUTION: Rotate the wheels at least a quarter turn and be certain the Park position mechanism is fully engaged.

- Loosen nut (A) and set manual lever (1) to the “P” position.

CAUTION: Do not apply force to the manual lever.

- Hold the control cable (2) and push it to direction of the arrow with a specified force.

Specified force : 9.8 N (1.0 kg, 2.2 lb)

- Temporarily tighten the nut with the control cable loose.

- Tighten the nut to the specified torque. Refer to TM-197, "Exploded View".

CAUTION: Hold the manual lever securely in the "P" position when tightening control cable nut.

How to erase permanent DTC

Description

Permanent DTC can be erased by driving each driving pattern.

ECM recognizes each driving pattern; it transmits signals to each control module when the driving is complete.

Each control module erases permanent DTC based on those signals. For details, refer to EC-151, "Description".

Stall test

Stall test

Work Procedure

INSPECTION

Check the engine oil level. Replenish if necessary. Refer to LU-7,

"Inspection".

Check for leak of the CVT fluid. Refer to TM-190, "Inspe ...

Other materials:

Operating the power liftgate (if so equipped)

WARNING

Make sure that all passengers have

their hands, etc., inside the vehicle before

closing the liftgate.

Do not leave children unattended inside

the vehicle. They could unknowingly activate

switches or controls. Unattended

children could become inv ...

C119A vacuum sensor

DTC Logic

DTC DETECTION LOGIC

DTC

Display Item

Malfunction detected condition

Possible causes

C119A

VACUUM SEN VOLT

When a malfunction is detected in supply power voltage

of vacuum sensor.

Harness or connector

Vacuum sensor (brake booster)

...

P0441 EVAP control system

DTC Description

DTC DETECTION LOGIC

In this evaporative emission (EVAP) control system, purge flow occurs during

non-closed throttle conditions.

Purge volume is related to air intake volume. Under normal purge conditions

(non-closed throttle), the EVAP

canister purge volume control solenoi ...