Nissan Rogue Service Manual: System description

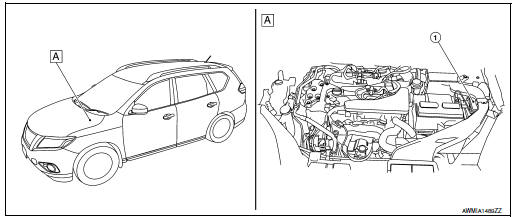

COMPONENT PARTS

Component Parts Location

- IPDM E/R

- Engine compartment (LH)

SYSTEM

RELAY CONTROL SYSTEM

RELAY CONTROL SYSTEM : System Description

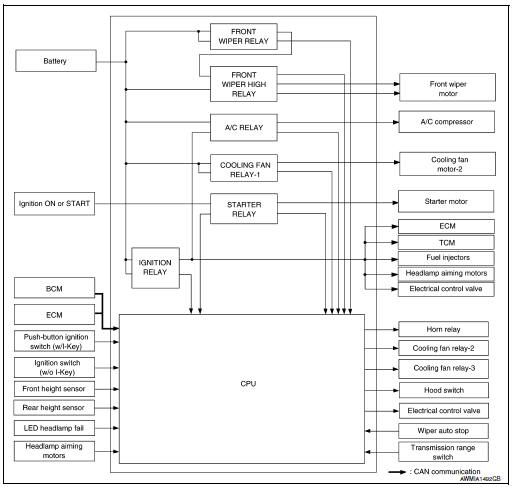

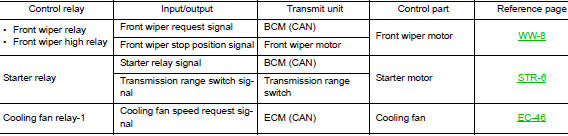

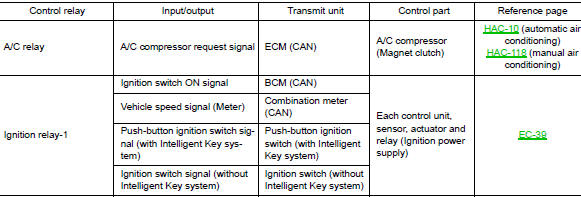

SYSTEM DIAGRAM

DESCRIPTION

IPDM E/R activates the internal control circuit to perform the relay ON-OFF control according to the input signals from various sensors and the request signals received from control units via CAN communication.

CAUTION: IPDM E/R integrated relays cannot be removed.

RELAY CONTROL SYSTEM : Fail-safe

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is impossible, IPDM E/R performs fail-safe control. After CAN communication recovers normally, it also returns to normal control.

If No CAN Communication Is Available With ECM

|

Control part |

Fail-safe operation |

| Cooling fan |

|

| A/C compressor | A/C relay OFF |

If No CAN Communication Is Available With BCM

|

Control part |

Fail-safe operation |

| Front wiper motor |

|

| Horn | Horn OFF |

| Ignition relay-1 | The status just before activation of fail-safe is maintained. |

| Starter motor | Starter relay OFF |

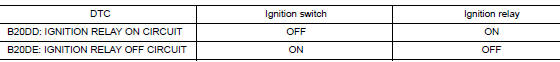

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

- IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay-1 inside it.

- IPDM E/R judges the ignition relay-1 error if the voltage differs between the contact circuit and the excitation coil circuit.

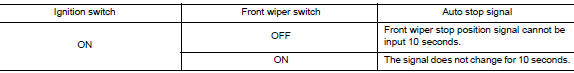

FRONT WIPER CONTROL

IPDM E/R detects front wiper stop position by a front wiper auto stop signal.

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R stops power supply to wiper after repeating a front wiper 10 second activation and 20 second stop five times.

NOTE: This operation status can be confirmed on the IPDM E/R “Data Monitor” that displays “BLOCK” for the item “WIP PROT” while the wiper is stopped.

STARTER MOTOR PROTECTION FUNCTION

IPDM E/R turns OFF the starter relay to protect the starter motor when the starter relay remains active for 90 seconds.

SMART FIELD-EFFECT TRANSISTOR (FET)

SMART FIELD-EFFECT TRANSISTOR (FET) : System Description

A smart Field-Effect Transistor (FET) is a transistor used to monitor and control current flow on module outputs.

The IPDM E/R uses a smart FET protection strategy to prevent module damage in the event of excessive current flow. The smart FET protection strategy monitors its outputs for excessive current, and when a fault occurs, shuts down the output and records a DTC.

POWER CONSUMPTION CONTROL SYSTEM

POWER CONSUMPTION CONTROL SYSTEM : System Description

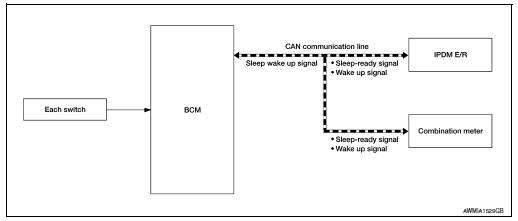

SYSTEM DIAGRAM

DESCRIPTION

Outline

- IPDM E/R incorporates a power consumption control function that reduces the power consumption according to the vehicle status.

- IPDM E/R changes its status (control mode) with the sleep wake up signal received from BCM via CAN communication.

Normal mode (wake-up)

- CAN communication is normally performed with other control units.

- Individual unit control by IPDM E/R is normally performed.

Low power consumption mode (sleep)

- Low power consumption control is active.

- CAN transmission is stopped.

Sleep Mode Activation

- IPDM E/R judges that the sleep-ready conditions are fulfilled when the ignition switch is OFF and none of the conditions below are present. Then it transmits a sleep-ready signal (ready) to BCM via CAN communication.

- Outputting signals to actuators

- Switches or relays operating

- Output requests are being received from control units via CAN communication.

- IPDM E/R stops CAN communication and enters the low power consumption mode when it receives a sleep wake up signal (sleep) from BCM and the sleep-ready conditions are fulfilled.

Wake-up Operation

- IPDM E/R changes from the low power consumption mode to the normal mode when it receives a sleep wake-up signal (wake up) from BCM or any of the following conditions is fulfilled. In addition, it transmits a sleep-ready signal (not-ready) to BCM via CAN communication to report the CAN communication start.

- Ignition switch ON

- An output request is received from a control unit via CAN communication.

DIAGNOSIS SYSTEM (IPDM E/R)

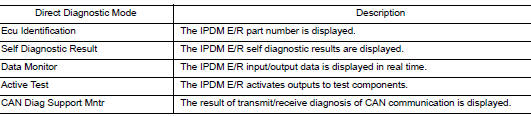

CONSULT Function (IPDM E/R)

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with IPDM E/R.

ECU IDENTIFICATION

The IPDM E/R part number is displayed.

SELF DIAGNOSTIC RESULT

Refer to PCS-20, "DTC Index".

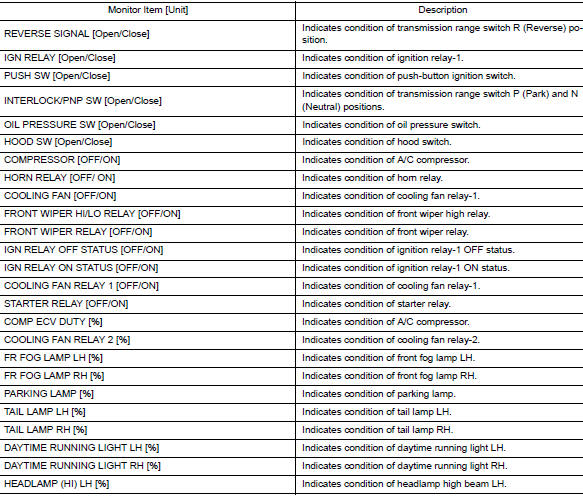

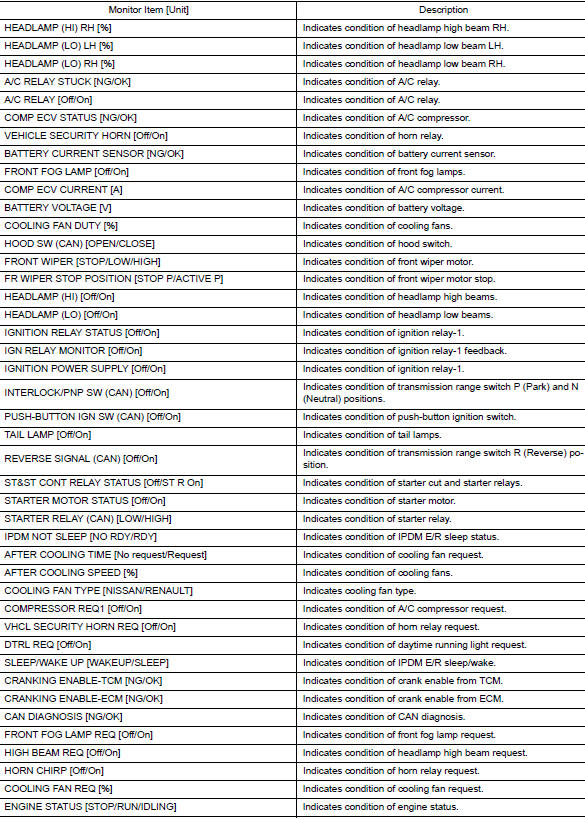

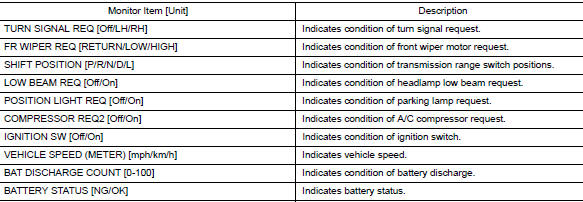

DATA MONITOR

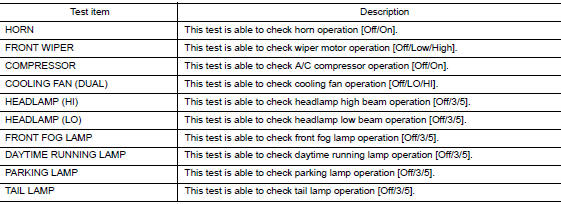

ACTIVE TEST

CAN DIAG SUPPORT MNTR

Refer to LAN-14, "CAN Diagnostic Support Monitor".

Precaution

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONE ...

ECU diagnosis information

ECU diagnosis information

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

Reference Value

VALUES ON THE DIAGNOSIS TOOL

TERMINAL LAYOUT

PHYSICAL VALUES

1: With Intelligent ...

Other materials:

Unbalance steering wheel turning force and return between

right and left

Description

Unbalance steering wheel turning force and return between right and left.

Diagnosis Procedure

1.CHECK THE ILLUMINATION OF THE EPS WARNING LAMP

Check the EPS warning lamp while engine is running.

Does the EPS warning lamp turn OFF?

YES >> GO TO 2.

NO >> Refer to STC ...

Rear suspension ARM

Exploded View

Rear suspension arm

Rubber washer (LH/RH)

Rear suspension arm bracket

Rear suspension arm stay

Front

Removal and Installation

REMOVAL

Remove the wheel hub and bearing. Refer to RAX-16, "Removal and

Installation".

Remove the coil spring. R ...

Air cleaner filter

Exploded view

Mass air flow sensor

Air cleaner filter

Air cleaner case (lower)

Air duct assembly

Grommet

Resonator bracket (front)

Resonator bracket (rear)

Resonator

Air duct

Mounting clip

Air duct assembly

Air duct assembly

...