Nissan Rogue Service Manual: Service data and specifications (SDS)

General Specification

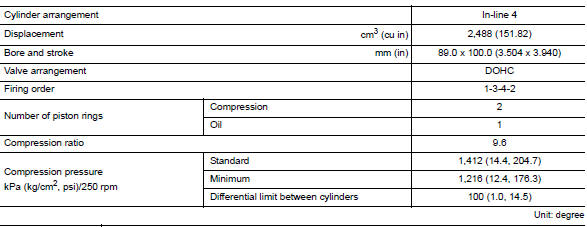

GENERAL SPECIFICATIONS

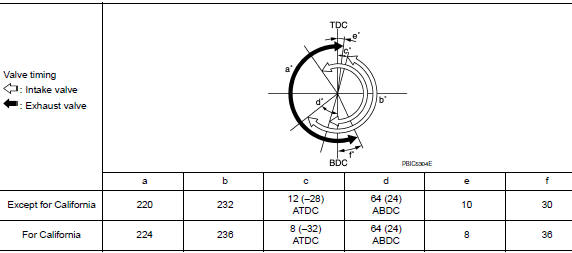

( ): Valve timing control ŌĆ£ONŌĆØ

Drive belt

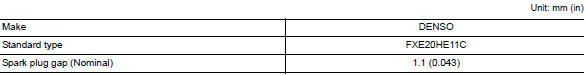

Spark Plug

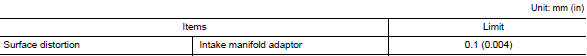

Intake Manifold

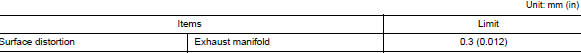

Exhaust Manifold

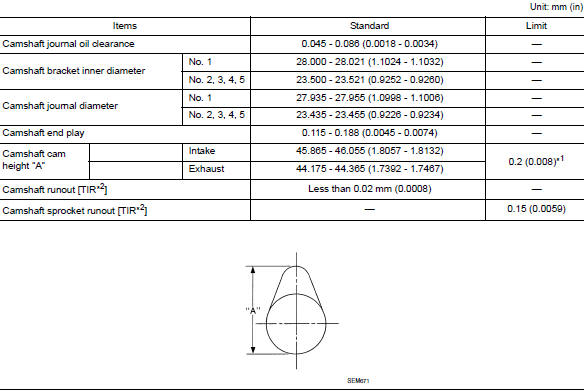

Camshaft

*1: Cam wear limit

*2: Total indicator reading

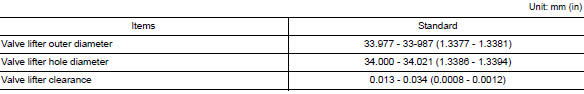

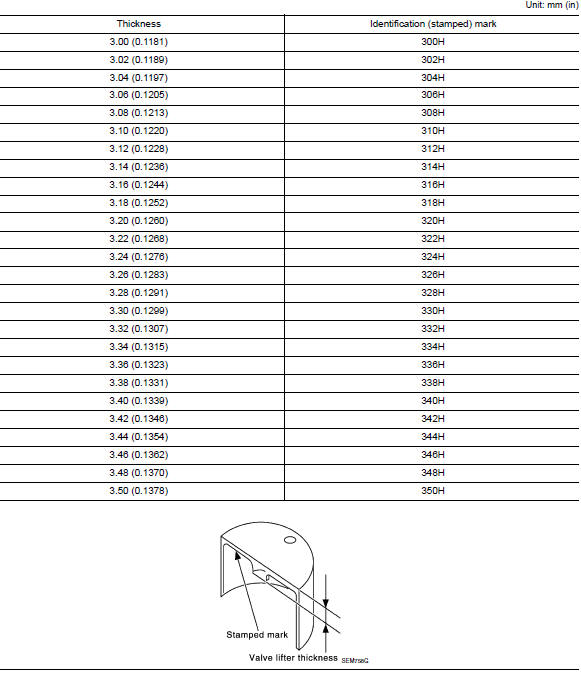

VALVE LIFTER

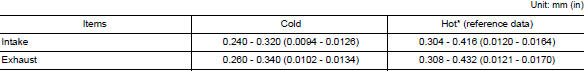

VALVE CLEARANCE

*: Approximately 80┬░C (176┬░F)

AVAILABLE VALVE LIFTER

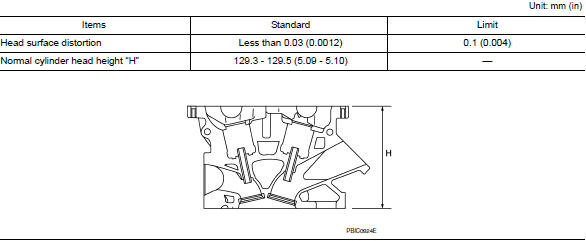

Cylinder Head

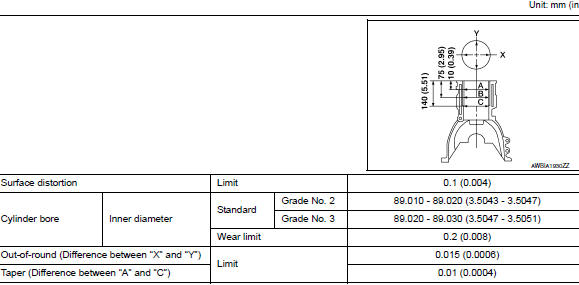

CYLINDER HEAD

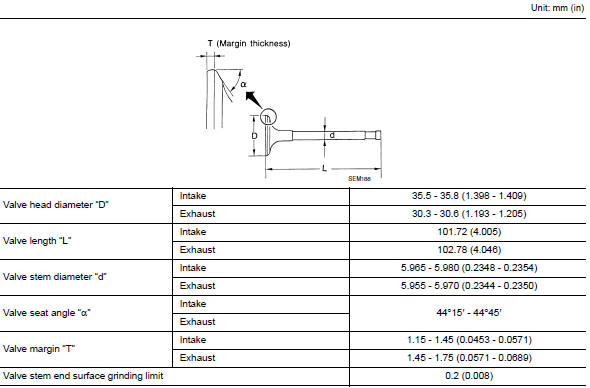

VALVE DIMENSIONS

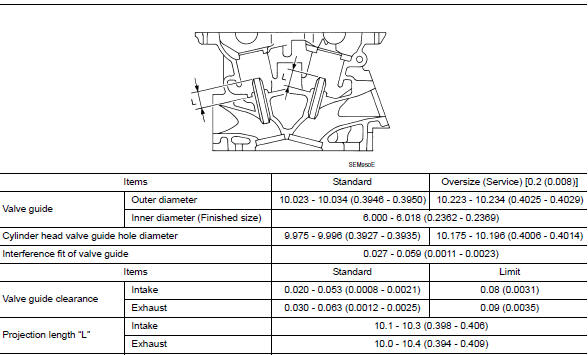

VALVE GUIDE

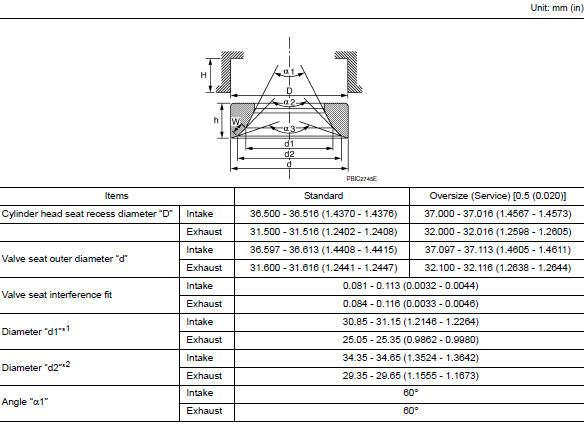

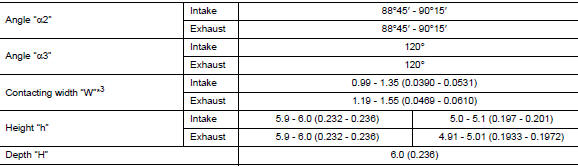

VALVE SEAT

*1: Diameter made by intersection point of conic angles ŌĆ£α1ŌĆØ and ŌĆ£α2ŌĆØ

*2: Diameter made by intersection point of conic angles ŌĆ£α2ŌĆØ and ŌĆ£α3ŌĆØ

*3: Machining data

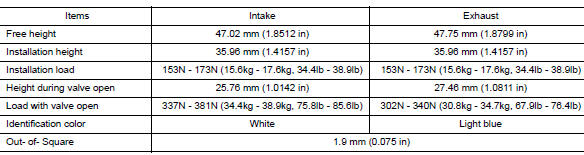

VALVE SPRING

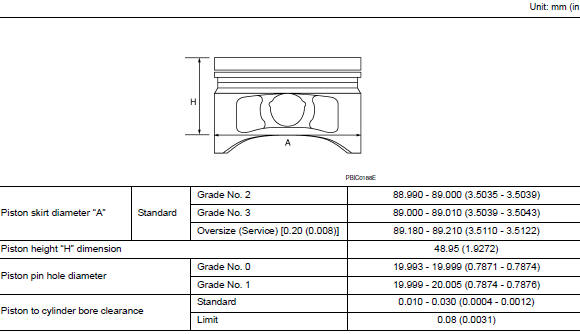

Cylinder Block

AVAILABLE PISTON

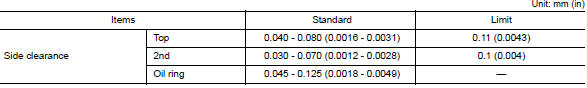

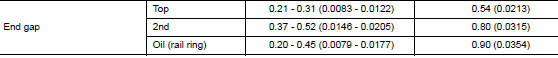

PISTON RING

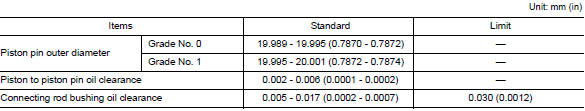

PISTON PIN

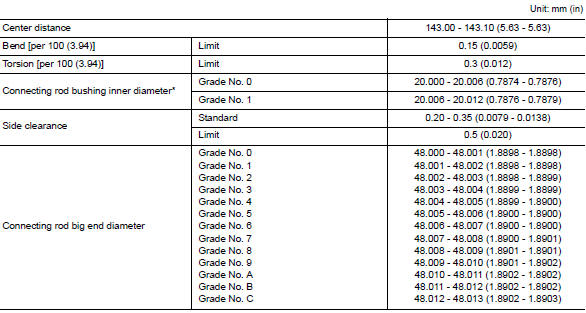

CONNECTING ROD

*: After installing in connecting rod

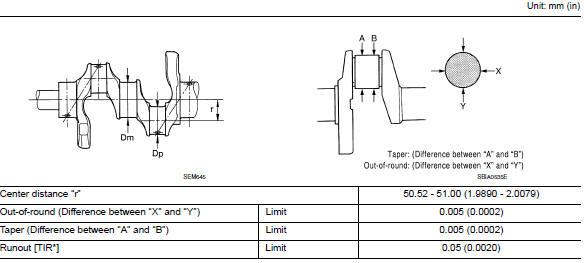

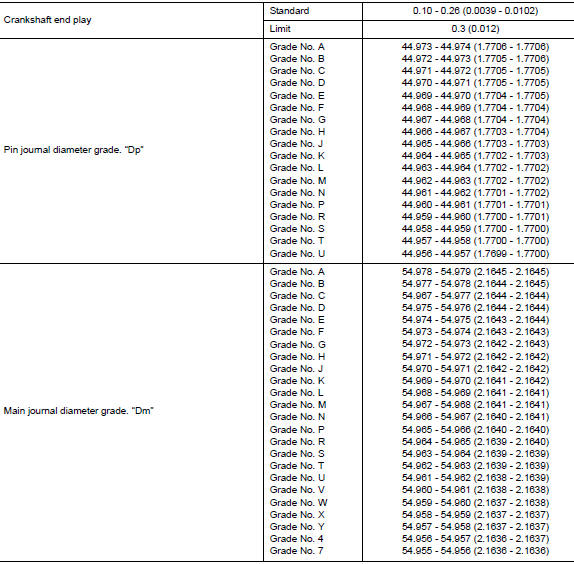

CRANKSHAFT

*: Total indicator reading

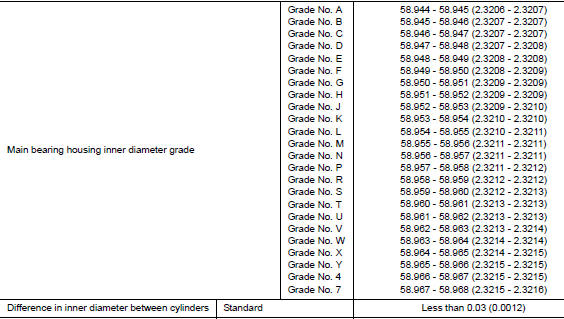

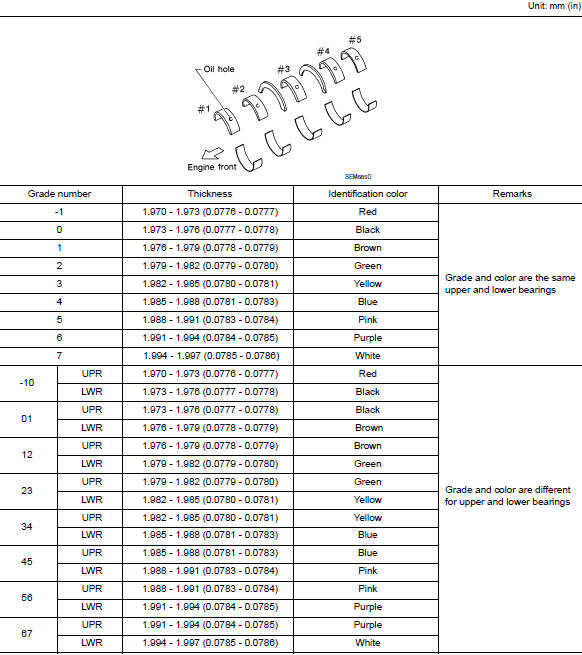

Main Bearing

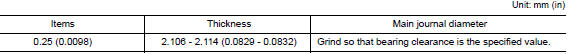

UNDERSIZE

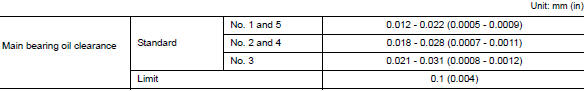

MAIN BEARING OIL CLEARANCE

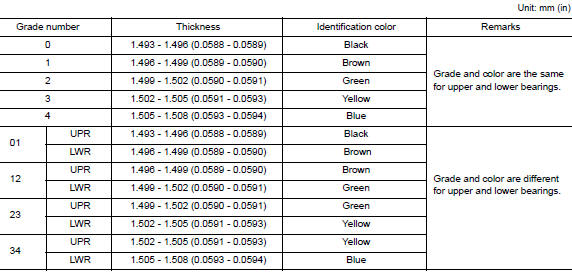

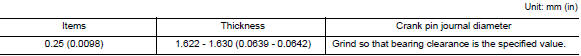

Connecting Rod Bearing

UNDERSIZE

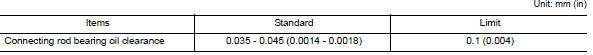

CONNECTING ROD BEARING OIL CLEARANCE

How to select piston and bearing

How to select piston and bearing

DESCRIPTION

Selection points

Selection parts

Selection items

Selection methods

Between cylinder block to

crankshaft

Main bearing

Main bearing grade (bearing

thick ...

Other materials:

Doors

When the doors are locked using one of the

following methods, the doors cannot be opened

using the inside or outside door handles. The

doors must be unlocked to open the doors.

WARNING

Always have the doors locked while

driving. Along with the use of seat belts,

this pro ...

Front disc brake

Brake Burnishing

CAUTION:

Burnish contact surfaces between brake pads and disc brake

rotor according to the following procedure

after refinishing the disc brake rotor, replacing brake pads or if a soft

pedal occurs at very low

mileage.

Be careful of vehicle speed. Brakes ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as ŌĆ£AIR BAGŌĆØ and ŌĆ£SEAT BELT

PRE-TENSIONERŌĆØ, used along

with a front seat belt, helps to reduce the risk or severity of injury to the

...