Nissan Rogue Service Manual: How to select piston and bearing

DESCRIPTION

| Selection points | Selection parts | Selection items | Selection methods |

| Between cylinder block to crankshaft | Main bearing | Main bearing grade (bearing thickness) | Determined by match of cylinder block bearing housing grade (inner diameter of housing) and crankshaft journal grade (outer diameter of journal) |

| Between crankshaft to connecting rod | Connecting rod bearing | Connecting rod bearing grade (bearing thickness) | Combining service grades for connecting rod big end inner diameter and crankshaft pin outer diameter determine connecting rod bearing selection |

| Between cylinder block to piston | Piston and piston pin assembly (The piston is available together with piston pin as an assembly) | Piston grade (piston outer diameter) | Piston grade = cylinder bore grade (inner diameter of bore) |

| *Between piston to connecting rod | — | — | — |

*For the service parts, the grade for fitting cannot be selected between a piston pin and a connecting rod.

(Only 0 grade is available.) The information at the shipment from the plant is described as a reference.

- The identification grade stamped on each part is the grade for the

dimension measured in new condition.

This grade cannot apply to reused parts.

- For reused or repaired parts, measure the dimension accurately. Determine the grade by comparing the measurement with the values of each selection table.

- For details of the measurement method of each part, the reuse standards, and the selection method of the selective fitting parts, follow the applicable procedures.

HOW TO SELECT A PISTON

When New Cylinder Block is Used:

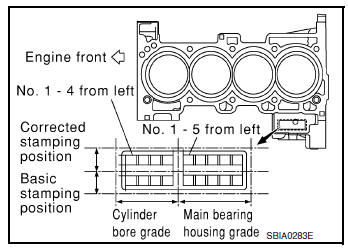

- Check the cylinder bore grade on rear left side of cylinder block, and select a piston of the same grade.

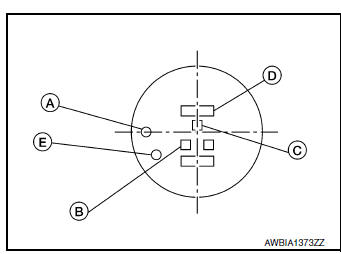

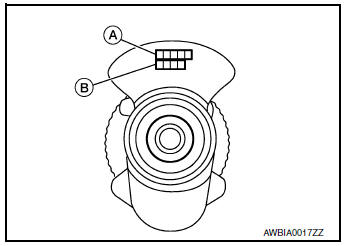

(A) : Front mark

(B) : Piston pin bore grade

(C) : Piston grade I.D. stamp

(D) : Piston crown I.D. code stamp

(E) : ID marks

- If there is a corrected stamp mark on the cylinder block, use it as a correct reference.

When a Cylinder Block is Reused:

- Measure the cylinder block bore inner diameter.

- Determine the bore grade by comparing the measurement with the values under the cylinder bore inner diameter of the "Piston Selection Table". Select the piston of the same grade.

Piston Selection Table

- For the piston selection table, refer to EM-120, "Cylinder Block".

NOTE:

- The piston is available together with piston pin as an assembly.

- The piston pin (piston pin bore) grade is provided only for the parts installed at the plant. For service parts, no grades can be selected. Only 0 grade is available.

HOW TO SELECT A CONNECTING ROD BEARING

When New Connecting Rod and Crankshaft are Used:

- Apply big end inside diameter grade stamped on connecting rod side face to the row in the "Connecting Rod Bearing Selection Table".

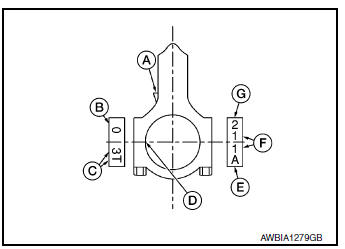

(A) : Oil splash

(B) : Small end diameter grade

(C) : Reference code

(D) : Bearing stopper groove

(E) : Reference code

(F) : Cylinder No.

(G) : Big end diameter grade

- Apply pin diameter grade (B) stamped on crankshaft front side to the column in the "Connecting Rod Bearing Selection Table".

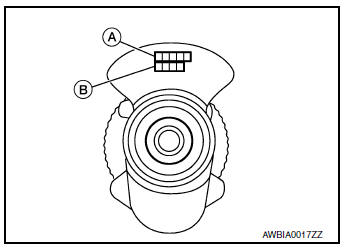

- Journal diameter grade (A)

- Read the symbol at the cross point of selected row and column in the "Connecting Rod Bearing Selection Table".

- Apply the symbol obtained to connecting rod bearing grade table to select.

When Crankshaft and Connecting Rod are Reused:

- Measure dimensions of the big end inner diameter of connecting rod and outer diameter of crankshaft pin individually.

- Apply the dimension measured to the "Connecting Rod Bearing Selection Table" below.

Connecting Rod Bearing Selection Table

Connecting Rod Bearing Grade Table. Refer to EM-125, "Connecting Rod Bearing".

Undersize Bearing Usage Guide

- When the specified oil clearance is not obtained with standard size connecting rod bearing, use undersize (US) bearing.

- When using undersize bearing, measure the bearing inner diameter with bearing installed, and grind the crankshaft pin so that the oil clearance satisfies the standard.

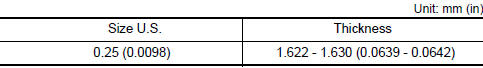

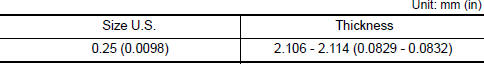

Bearing Undersize Table

CAUTION: In grinding the crankshaft pin to use undersize bearings, do not damage the fillet R (All crankshaft pins).

HOW TO SELECT A MAIN BEARING

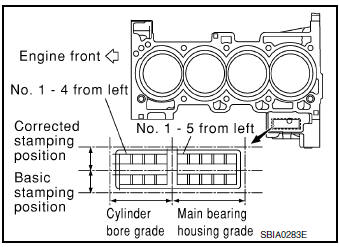

When New Cylinder Block and Crankshaft are Used:

- "Main Bearing Selection Table" rows correspond to bearing housing grade on rear left side of cylinder block.

- If there is a corrected stamp mark on the cylinder block, use it as a correct reference.

- Apply journal diameter grade (A) stamped on crankshaft front side to column in "Main Bearing Selection Table".

(B) : Pin diameter grade

- Find value at crossing of row and column in "Main Bearing Selection Table".

CAUTION:

- There are two main bearing selection tables. One is for odd-numbered journals (1, 3, and 5) and the other is for even-numbered journals (2 and 4). Make certain to use the appropriate table. This is due to differences in the specified clearances.

- Apply the symbol obtained to "Main Bearing Grade Table" to select.

NOTE:

- Service parts are available as a set of both upper and lower.

When Cylinder Block and Crankshaft are Reused:

- Measure inner diameter of cylinder block main bearing housing and outer diameter of crankshaft journal.

- Apply measurement in above step 1 to the "Main Bearing Selection Table".

- Follow steps 3 and 4 in "When New Cylinder Block and Crankshaft are Used".

Main Bearing Selection Table (No.1, 3, and No.5 journals)

Main Bearing Selection Table (No.2,and 4 journals)

Main Bearing Grade Table (All Journals) Refer to EM-123, "Main Bearing".

Use Undersize Bearing Usage Guide

- Use undersize (U.S.) bearing when oil clearance with standard size main bearing is not within specification.

- When using undersize (U.S.) bearing, measure the bearing inner diameter with the bearing installed and grind journal until oil clearance falls within specification.

Bearing Undersize Table

CAUTION: Do not damage fillet R when grinding crankshaft journal in order to use an undersize bearing (all journals).

Cylinder block

Cylinder block

Exploded View

Cylinder block

Top ring

Second ring

Oil ring

Snap ring

Piston

Connecting rod

Piston pin

Connecting rod bearing

Rear oi ...

Service data and specifications (SDS)

Service data and specifications (SDS)

General Specification

GENERAL SPECIFICATIONS

( ): Valve timing control “ON”

Drive belt

Spark Plug

Intake Manifold

Exhaust Manifold

Camshaft

*1: Cam wear limit

*2: To ...

Other materials:

Supplemental air bag warning labels

SRS Air Bag Warning Labels

SRS Air Bag Warning Labels

The warning labels are located on the surface

of the sun visor.

Warning labels about the supplemental frontimpact

air bag system are placed in the vehicle as

shown in the illustration.

WARNINGExtreme Hazard! Do not us ...

Forward Collision Warning (FCW) system

(if so equipped)

The Forward Collision Warning (FCW) system

will warn the driver by flashing the FCW indicator

light and providing a warning chime when your

vehicle is getting close to the vehicle ahead in the

traveling lane.

The FCW system will function when your vehicle

is driven at speeds of approximately ...

C1729 vehicle speed signal

DTC Logic

NOTE:

The Signal Tech II Tool [- (J-50190)] can be used to perform the following

functions. Refer to the Signal Tech II

User Guide for additional information.

Activate and display TPMS sensor IDs

Display tire pressure reported by the TPMS sensor

Read TPMS DTC ...