Nissan Rogue Service Manual: Refrigerant pressure sensor

Component Function Check

1.CHECK REFRIGERANT PRESSURE SENSOR FUNCTION

- Start engine and warm it up to normal operating temperature.

- Turn A/C switch and blower fan switch ON.

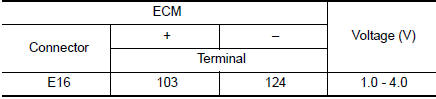

- Check the voltage between ECM harness connector terminals under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-482, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK REFRIGERANT PRESSURE SENSOR POWER SUPPLY

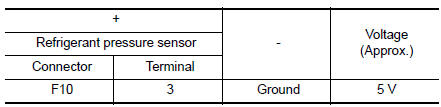

- Disconnect refrigerant pressure sensor harness connector.

- Turn ignition switch ON.

- Check the voltage between refrigerant pressure sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK REFRIGERANT PRESSURE SENSOR POWER SUPPLY CIRCUIT

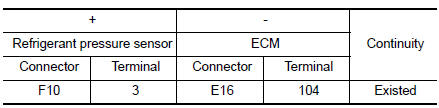

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

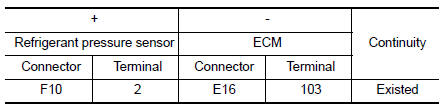

- Check the continuity between refrigerant pressure sensor harness connector and ECM harness connector.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

3.CHECK REFRIGERANT PRESSURE SENSOR GROUND CIRCUIT

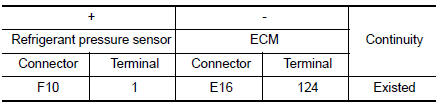

- Turn ignition switch OFF.

- Disconnect ECM harness connector

- Check the continuity between refrigerant pressure sensor harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK REFRIGERANT PRESSURE SENSOR INPUT SIGNAL CIRCUIT

- Check the continuity between refrigerant pressure sensor harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK INTERMITTENT INCIDENT

Check intermittent incident. Refer to GI-41, "Intermittent Incident".

Is the inspection result normal? YES >> Replace refrigerant pressure sensor. Refer to HAC-108, "Removal and Installation" (with automatic air conditioner) or HAC-183, "Removal and Installation" (with manual air conditioner).

NO >> Repair or replace error-detected parts.

On board refueling vapor recovery (ORVR)

On board refueling vapor recovery (ORVR)

Component Function Check

1.CHECK ORVR FUNCTION

Check whether the following symptoms are present.

Fuel odor from EVAP canister is strong.

Cannot refuel/Fuel odor from the fuel fille ...

Sensor power supply2 circuit

Sensor power supply2 circuit

Description

ECM supplies a voltage of 5 V to some of the sensors systematically divided

into 2 groups, respectively.

Accordingly, when a short circuit develops in a sensor power source, a

malf ...

Other materials:

Diagnosis and repair workflow

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1. OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the

conditions and environment under

which the malfunction occurred.

>> GO TO 2.

2. CONFIRM THE SYMPTOM

Check the malfunction on the ...

Door mirror

Exploded View

Door mirror

Door mirror corner finisher

Door mirror rear finisher

Side turn signal lamp

Side camera (if equipped)

Door mirror glass

Pawl

Removal and Installation

REMOVAL

Remove front door finisher. Refer to INT-15, "Removal and

...

Second row seat belt

Exploded View

Seat belt retractor (center)

Seat belt D-ring bracket (LH/

RH)

Seat belt hook (LH/RH)

Seat belt retractor (RH)

Seat belt D-ring bolt cover

(LH/RH)

Seat belt buckle (RH)

Seat belt buckle (center)

Seat belt buckle (LH)

Seat belt retractor (LH)

&nbs ...