Nissan Rogue Service Manual: Rear wiper motor circuit

Component Function Check

1. CHECK REAR WIPER ON OPERATION

CONSULT ACTIVE TEST

CONSULT ACTIVE TEST

- Select "RR WIPER" of BCM active test item.

- While operating the test item, check rear wiper operation.

ON : Rear wiper ON operation

OFF : Stop the rear wiper.

Is rear wiper operation normal? YES >> Rear wiper motor circuit is normal.

NO >> Refer to WW-47, "Diagnosis Procedure".

Diagnosis Procedure

Regarding Wiring Diagram information, refer to WW-28, "Wiring Diagram".

1. CHECK REAR WIPER MOTOR OUTPUT VOLTAGE

CONSULT ACTIVE TEST

CONSULT ACTIVE TEST

- Turn the ignition switch OFF.

- Disconnect rear wiper motor.

- Turn the ignition switch ON.

- Select RR WIPER of BCM active test item.

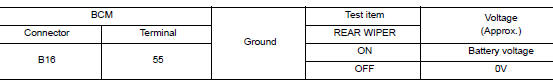

- While operating the test item, check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 3.

2. CHECK REAR WIPER MOTOR GROUND CIRCUIT

- Turn the ignition switch OFF.

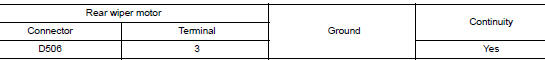

- Check continuity between rear wiper motor harness connector and ground.

Is the inspection result normal? YES >> Replace rear wiper motor. Refer to WW-71, "Removal and Installation".

NO >> Repair or replace harness.

3. CHECK REAR WIPER MOTOR OPEN CIRCUIT

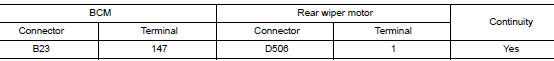

Check continuity between BCM harness connector and rear wiper motor harness connector.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4. CHECK REAR WIPER MOTOR SHORT CIRCUIT

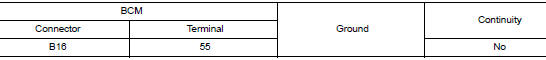

Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> Repair or replace harness.

NO >> Replace BCM. Refer to BCS-75, "Removal and Installation" (with Intelligent Key system) or BCS- 135, "Removal and Installation" (without Intelligent Key system).

Washer switch

Washer switch

Description

Washer switch is integrated with the combination switch.

Combination switch (wiper and washer switch) switches polarity

between front washer operating and rear

washer oper ...

Rear wiper auto stop signal circuit

Rear wiper auto stop signal circuit

Component Function Check

1. CHECK REAR WIPER (AUTO STOP) OPERATION

CONSULT DATA MONITOR

Select WIPER of BCM data monitor item.

Operate the rear wiper.

Check that RR WIPER ...

Other materials:

Divide-n-hide® adjustable floor (if so equipped)

Divide-n-hide® adjustable floor (if so equipped)

WARNINGDo not put objects heavier than 165 lbs

(75 kg) on the Divide-N-Hide® while in the

mid position. In the upper position, objects

should not weigh more than 30 lbs

(14 kg).

There are multiple positions for the adju ...

Service data and specifications (SDS)

General Specifications

Preload Torque

Drive Gear Runout

Backlash

Differential Side Gear Clearance

...

Periodic maintenance

REAR PROPELLER SHAFT

Inspection

APPEARANCE AND NOISE

Check the propeller shaft tube surface for dents or cracks. If

malfunction is detected, replace propeller shaft

assembly.

If center bearing is noisy or damaged, replace propeller shaft

assembly.

VIBRATION

If vibrati ...