Nissan Rogue Service Manual: Rear washer nozzle and tube

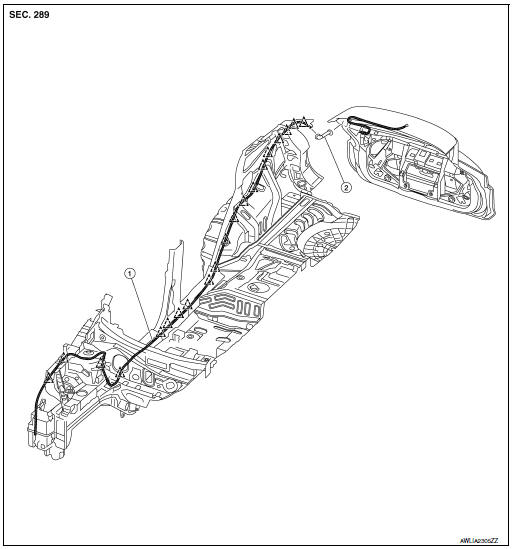

Exploded View

- Rear washer tube

- Rear grommet

Clip

Clip

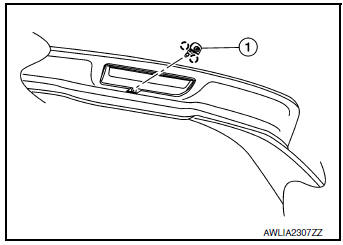

Removal and Installation - Rear Washer Nozzle

REMOVAL

- Remove rear access panel. Refer to INT-38, "Exploded View".

- Release pawls and remove rear washer nozzle (1).

: Pawl

: Pawl

INSTALLATION

Installation in the reverse order of removal.

Removal and Installation - Rear Washer Tube

REMOVAL

- Remove engine side cover (RH). Refer to EXT-28, "FENDER PROTECTOR : Exploded View".

- Release clips and remove front air spoiler.

- Remove engine under cover. Refer to EXT-37, "ENGINE UNDER COVER : Removal and Installation".

- Partially remove fender protector (RH). Refer to EXT-37, "ENGINE UNDER COVER : Removal and Installation".

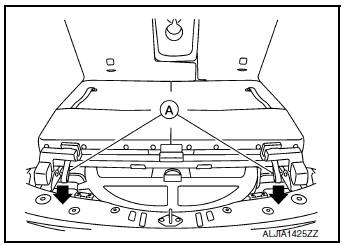

- Release seat latches by pulling straps (A) rearward, then lift seat from seat strikers (LH/RH).

- Remove dash side finisher (RH). Refer to INT-24, "DASH SIDE FINISHER : Removal and Installation".

- Remove center pillar lower finisher (RH). Refer to INT-22, "CENTER PILLAR LOWER FINISHER : Removal and Installation".

- Remove luggage rear plate. Refer to INT-37, "LUGGAGE REAR PLATE : Removal and Installation".

- Remove luggage side upper finisher (LH/RH). Refer to INT-36, "LUGGAGE SIDE UPPER FINISHER : Removal and Installation".

- Release rear clips and partially remove headliner. Refer to INT-29, "Exploded View".

- Disconnect rear washer tube from washer tank and rear washer nozzle.

- Release clips and remove rear washer tube.

INSTALLATION

Installation is in the reverse order of removal.

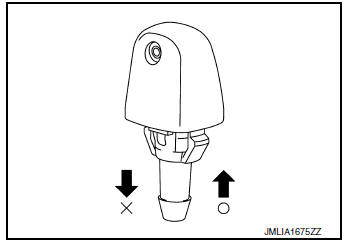

Inspection and Adjustment

INSPECTION

Check that air can pass through the nozzle by blowing into the nozzle and that air cannot flow in the opposite direction.

O: Air can go

X: Air cannot go

ADJUSTMENT

If operating properly, spray positions should match the positions shown. If spray positions do not match, confirm the rear washer nozzle is properly seated and working properly. If the spray positions still do not match as shown, then replace the rear washer nozzle. Refer to WW-72, "Removal and Installation - Rear Washer Nozzle"

- Black print

- Wiping area

- Spray target area

- 12.8

- 12.8

- 25.7

- 15.6

- 20.6

Rear wiper motor

Rear wiper motor

Exploded View

Rear wiper motor

Back door

Rear wiper motor harness

Removal and Installation

REMOVAL

Remove rear wiper arm. Refer to WW-69, "Removal and Installation&quo ...

Service data and specifications (sds)

Service data and specifications (sds)

Specifications

WINDSHIELD WASHER FLUID

...

Other materials:

Abbreviations

Abbreviation List

The following ABBREVIATIONS are used:

...

Specifications

Engine

Model

QR25DE

Type

Gasoline, 4-cycle, DOHC

Cylinder arrangement

4-cylinder

Bore x Stroke

in (mm)

3.5 x 3.9 (89.0 x 100.0)

Displacement

cu in (cm3)

151.82 (2,488)

Firing order

1-3-4-2

Idle speed

No ...

Push-Button Ignition Switch (if so equipped)

WARNINGDo not operate the push-button ignition

switch while driving the vehicle except in

an emergency. (The engine will stop when

the ignition switch is pushed 3 consecutive

times in quick succession or the ignition

switch is pushed and held for more

than 2 seconds.) If the ...