Nissan Rogue (T33) 2021-Present Service Manual: P2a01 Ho2s2

DTC Description

The heated oxygen sensor 2 has a much longer switching time between rich and lean than the air fuel ratio (A/F) sensor 1. The oxygen storage capacity of the three way catalyst (manifold) causes the longer switching time.

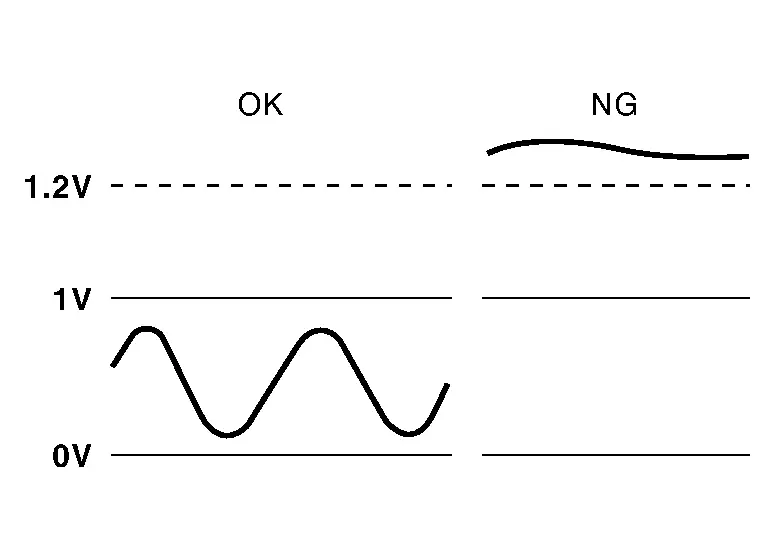

MALFUNCTION A

To judge the malfunctions of heated oxygen sensor 2, ECM monitors whether the voltage is unusually high during various driving conditions such as fuel cut.

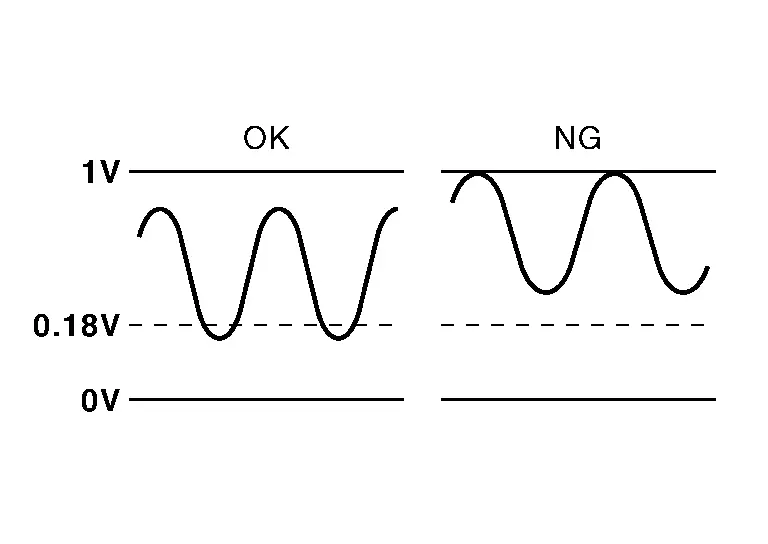

MALFUNCTION B

To judge the malfunctions of heated oxygen sensor 2, ECM monitors whether the minimum voltage is excessively high during various driving conditions such as fuel cut.

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | |||

| P2A01 | 00 |

O2 sensor bank 1 sensor 2 (O2 Sensor Circuit Range/Performance Bank 1 Sensor 2) |

A | Diagnosis condition | Engine running at fuel cut |

| Signal (terminal) | Heated oxygen sensor 2 signal | ||||

| Threshold | An excessively high voltage from the sensor is sent to ECM | ||||

| Diagnosis delay time | — | ||||

| B | Diagnosis condition | Engine running at fuel cut | |||

| Signal (terminal) | Heated oxygen sensor 2 signal | ||||

| Threshold | The minimum voltage from the sensor is not reached to the specified voltage | ||||

| Diagnosis delay time | — | ||||

POSSIBLE CAUSE

P2A01-A

-

Harness or connectors (The heated oxygen sensor 2 circuit is open or shorted.)

-

Heated oxygen sensor 2

P2A01-B

-

Harness or connectors (The heated oxygen sensor 2 circuit is open or shorted.)

-

Heated oxygen sensor 2

-

Fuel pressure

-

Fuel injector

FAIL-SAFE

Not applicable

DTC Confirmation Procedure

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

>>

GO TO 2.

DTC CONFIRMATION PROCEDURE FOR MALFUNCTION A

-

Start engine and warm it up to the normal operating temperature.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Restart engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

-

Check 1st trip DTC.

Is 1st trip DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>With CONSULT: GO TO 3.

NO-2>>Without CONSULT: GO TO 5.

DTC CONFIRMATION PROCEDURE FOR MALFUNCTION B-1

With CONSULT

With CONSULT

Test condition: For better results, perform “DTC WORK SUPPORT” at a temperature of 0 to 30°C (32 to 86°F).

-

Turn ignition switch ON and select “DATA MONITOR” mode of “ENGINE” using CONSULT.

-

Start engine and warm it up to the normal operating temperature.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Restart engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

-

Let engine idle for 1 minute.

-

Check that “COOLANT TEMP/S” indicates more than 70°C (158°F).

If not, warm up engine and go to next step when “COOLANT TEMP/S” indication reaches 70°C (158°F).

-

Open engine hood.

-

Select “HO2S2 (B1) P1146” of “HO2S2” in “DTC WORK SUPPORT” mode of “ENGINE” using CONSULT.

-

Follow the instruction of CONSULT display.

NOTE:

NOTE:

It will take at most 10 minutes until “COMPLETED”is displayed.

-

Touch “SELF-DIAG RESULTS”.

Which is displayed on CONSULT screen?

OK-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

OK-2>>Confirmation after repair: INSPECTION END

NG>>Refer to DTC Diagnosis Procedure.

CAN NOT BE DIAGNOSED>>GO TO 4.

DTC CONFIRMATION PROCEDURE FOR MALFUNCTION B-2

-

Turn ignition switch OFF and leave the Nissan Ariya vehicle in a cool place (soak the vehicle).

-

Perform DTC confirmation procedure again.

>>

GO TO 3.

PERFORM COMPONENT FUNCTION CHECK

Perform Component Function Check. Refer to Component Function Check.

Is the inspection result normal?

YES-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

YES-2>>Confirmation after repair: INSPECTION END

NO>>Refer to DTC Diagnosis Procedure.

DTC Diagnosis Procedure

INSPECTION START

Confirm the detected malfunction (A or B). Refer to DTC Description.

Which malfunction is detected?

A>>GO TO 2.

B>>GO TO 7.

CHECK HEATED OXYGEN SENSOR 2 CONNECTOR

-

Disconnect heated oxygen sensor 2 (HO2S2) harness connector.

-

Check that water is not inside connectors.

| There is no leakage. |

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace malfunctioning part.

CHECK HO2S2 GROUND CIRCUIT

-

Ignition switch OFF.

-

Disconnect ECM harness connector.

-

Disconnect heated oxygen sensor 2 (HO2S2) harness connector.

-

Check the continuity between HO2S2 harness connector and ECM harness connector.

HO2S2 ECM Continuity Connector Terminal Connector Terminal F67 1 F71 97 Existed -

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair or replace malfunctioning part.

CHECK HO2S2 INPUT SIGNAL CIRCUIT

-

Check the continuity between HO2S2 harness connector and ECM harness connector.

HO2S2 ECM Continuity Connector Terminal Connector Terminal F67 2 F71 92 Existed -

Check the continuity between HO2S2 harness connector and ground, or ECM harness connector and ground.

HO2S2 — Continuity Connector Terminal F67 2 Ground Not existed ECM — Continuity Connector Terminal F71 92 Ground Not existed -

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES>>GO TO 5.

NO>>Repair or replace malfunctioning part.

CHECK HEATED OXYGEN SENSOR 2

Refer to Component Inspection.

Is the inspection result normal?

YES>>INSPECTION END

NO>>GO TO 6.

REPLACE HEATED OXYGEN SENSOR 2

Replace heated oxygen sensor 2. Refer to Exploded View.

>>

INSPECTION END

PERFORM AIR FUEL RATIO INITIAL LEARNING

-

Start engine and warm it up to the normal operating temperature.

-

Clear the air fuel ratio initial learning. Refer to Work Procedure.

-

Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0172 detected? Is it difficult to start engine?

YES>>Perform trouble diagnosis for DTC P0172. Refer to DTC Description.

NO>>GO TO 8.

CHECK HEATED OXYGEN SENSOR 2 GROUND CIRCUIT

-

Turn ignition switch OFF.

-

Disconnect ECM harness connector.

-

Disconnect heated oxygen sensor 2 (HO2S2) harness connector.

-

Check the continuity between HO2S2 harness connector and ECM harness connector.

HO2S2 ECM Continuity Connector Terminal Connector Terminal F67 1 F71 97 Existed -

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES>>GO TO 9.

NO>>Repair or replace malfunctioning part.

CHECK HO2S2 INPUT SIGNAL CIRCUIT

-

Check the continuity between HO2S2 harness connector and ECM harness connector.

HO2S2 ECM Continuity Connector Terminal Connector Terminal F67 2 F71 92 Existed -

Check the continuity between HO2S2 harness connector and ground, or ECM harness connector and ground.

HO2S2 — Continuity Connector Terminal F67 2 Ground Not existed ECM — Continuity Connector Terminal F71 92 Ground Not existed -

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES>>GO TO 10.

NO>>Repair or replace malfunctioning part.

CHECK HEATED OXYGEN SENSOR 2

Refer to Component Inspection.

Is the inspection result normal?

YES>>INSPECTION END

NO>>GO TO 11.

REPLACE HEATED OXYGEN SENSOR 2

Replace heated oxygen sensor 2. Refer to Exploded View.

>>

INSPECTION END

Other materials:

P0446 Evap Canister Vent Control Valve

DTC Description

DTC DETECTION LOGIC DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P0446

00

VENT CONTROL VALVE

(EVAP System Vent Control Circuit)

Diagnosis condition

Engine running at idle

Signal (terminal)

EVAP canister vent control ...

Kr15ddt. Precaution. Precautions

Precautions

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT

PRE-TENSIONER”, used along with a front seat belt, helps to reduce the

risk or severity of injury to the driver and ...

Diagnosis System (head up Display Unit)

CONSULT Function (HEAD UP DISPLAY)

APPLICATION ITEMSCONSULT can perform the following diagnosis modes via CAN communication and the combination meter. Diagnosis mode Function

Self diagnosis result

The Head Up Display unit self diagnosis results are displayed.

ECU Identification

The H ...