Nissan Rogue (T33) 2021-Present Service Manual: P2270 Ho2s2

DTC Description

The heated oxygen sensor 2 has a much longer switching time between rich and lean than the air fuel ratio (A/F) sensor 1. The oxygen storage capacity of the three way catalyst (manifold) causes the longer switching time.

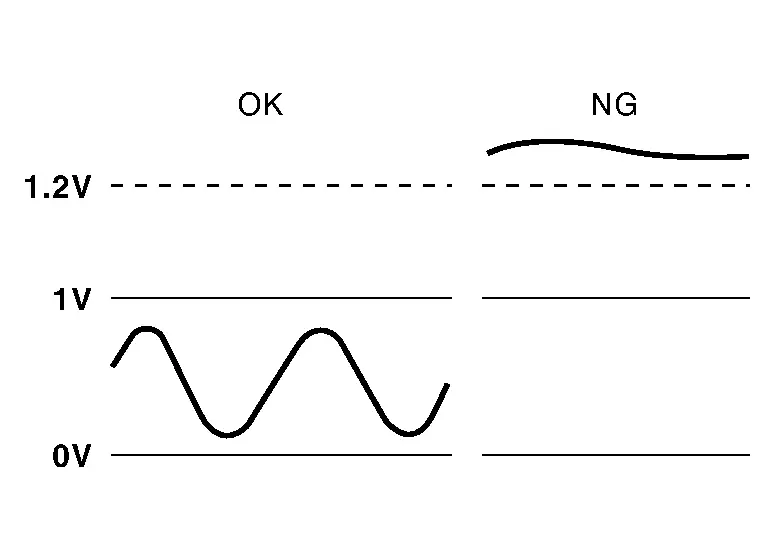

MALFUNCTION A

To judge the malfunctions of heated oxygen sensor 2, ECM monitors whether the voltage is unusually high during various driving conditions such as fuel cut.

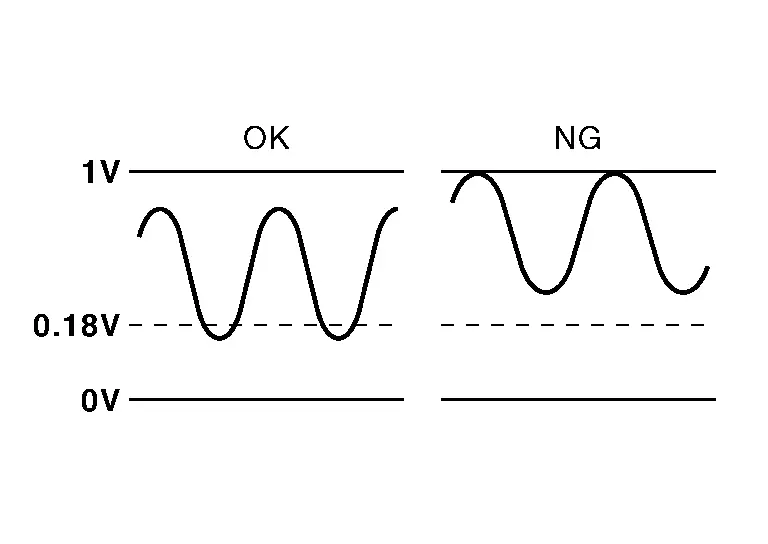

MALFUNCTION B

To judge the malfunctions of heated oxygen sensor 2, ECM monitors whether the minimum voltage is excessively high during various driving conditions such as fuel cut.

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | |||

| P2270 | 00 |

O2 sensor signal bank 1 sensor 2 (O2 Sensor Signal Biased/Stuck Lean Bank 1 Sensor 2) |

A | Diagnosis condition | Engine running at fuel cut |

| Signal (terminal) | Heated oxygen sensor 2 signal | ||||

| Threshold | An excessively high voltage from the sensor is sent to ECM | ||||

| Diagnosis delay time | — | ||||

| B | Diagnosis condition | Engine running at fuel cut | |||

| Signal (terminal) | Heated oxygen sensor 2 signal | ||||

| Threshold | The minimum voltage from the sensor is not reached to the specified voltage | ||||

| Diagnosis delay time | — | ||||

POSSIBLE CAUSE

P2270-A

-

Harness or connectors (The heated oxygen sensor 2 circuit is open or shorted.)

-

Heated oxygen sensor 2

P2270-B

-

Harness or connectors (The heated oxygen sensor 2 circuit is open or shorted.)

-

Heated oxygen sensor 2

-

Fuel pressure

-

Fuel injector

FAIL-SAFE

Not applicable

DTC Confirmation Procedure

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

>>

GO TO 2.

DTC CONFIRMATION PROCEDURE FOR MALFUNCTION A

-

Start engine and warm it up to the normal operating temperature.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Restart engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

-

Check 1st trip DTC.

Is 1st trip DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>With CONSULT: GO TO 3.

NO-2>>Without CONSULT: GO TO 6.

DTC CONFIRMATION PROCEDURE FOR MALFUNCTION B-1

With CONSULT

With CONSULT

Test condition: For better results, perform “DTC WORK SUPPORT” at a temperature of 0 to 30°C (32 to 86°F).

-

Turn ignition switch ON and select “DATA MONITOR” mode of “ENGINE” using CONSULT.

-

Start engine and warm it up to the normal operating temperature.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Restart engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

-

Let engine idle for 1 minute.

-

Check that “COOLANT TEMP/S” indicates more than 70°C (158°F).

If not, warm up engine and go to next step when “COOLANT TEMP/S” indication reaches 70°C (158°F).

-

Open engine hood.

-

Select “HO2S2 (B1) P1146” of “HO2S2” in “DTC WORK SUPPORT” mode of “ENGINE” using CONSULT.

-

Follow the instruction of CONSULT display.

NOTE:

NOTE:

It will take at most 10 minutes until “COMPLETED”is displayed.

-

Touch “SELF-DIAG RESULTS”.

Which is displayed on CONSULT screen?

OK-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

OK-2>>Confirmation after repair: GO TO 5.

NG>>Refer to DTC Diagnosis Procedure.

CAN NOT BE DIAGNOSED>>GO TO 4.

DTC CONFIRMATION PROCEDURE FOR MALFUNCTION B-2

-

Turn ignition switch OFF and leave the Nissan Ariya vehicle in a cool place (soak the vehicle).

-

Perform DTC confirmation procedure again.

>>

GO TO 3.

ERASE DTC

Erase DTC of ECM.

>>

INSPECTION END

PERFORM COMPONENT FUNCTION CHECK

Perform Component Function Check. Refer to Component Function Check.

Is the inspection result normal?

YES-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

YES-2>>Confirmation after repair: GO TO 7.

NO>>Refer to DTC Diagnosis Procedure.

ERASE DTC

Erase DTC of ECM.

>>

INSPECTION END

DTC Diagnosis Procedure

INSPECTION START

Confirm the detected malfunction (A or B). DTC Description

Which malfunction is detected?

A>>GO TO 2.

B>>GO TO 7.

CHECK HEATED OXYGEN SENSOR 2 CONNECTOR

-

Disconnect heated oxygen sensor 2 (HO2S2) harness connector.

-

Check that water is not inside connectors.

| There is no leakage. |

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace malfunctioning part.

CHECK HO2S2 GROUND CIRCUIT

-

Turn ignition switch OFF.

-

Disconnect ECM harness connector.

-

Disconnect heated oxygen sensor 2 (HO2S2) harness connector.

-

Check the continuity between HO2S2 harness connector and ECM harness connector.

HO2S2 ECM Continuity Connector Terminal Connector Terminal F67 1 F71 97 Existed -

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair or replace malfunctioning part.

CHECK HO2S2 INPUT SIGNAL CIRCUIT

-

Check the continuity between HO2S2 harness connector and ECM harness connector.

HO2S2 ECM Continuity Connector Terminal Connector Terminal F67 2 F71 92 Existed -

Check the continuity between HO2S2 harness connector and ground, or ECM harness connector and ground.

HO2S2 — Continuity Connector Terminal F67 2 Ground Not existed ECM — Continuity Connector Terminal F71 92 Ground Not existed -

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES>>GO TO 5.

NO>>Repair or replace malfunctioning part.

CHECK HEATED OXYGEN SENSOR 2

Refer to Component Inspection.

Is the inspection result normal?

YES>>INSPECTION END

NO>>GO TO 6.

REPLACE HEATED OXYGEN SENSOR 2

Replace heated oxygen sensor 2. Refer to Exploded View.

>>

INSPECTION END

PERFORM AIR FUEL RATIO INITIAL LEARNING

-

Start engine and warm it up to the normal operating temperature.

-

Clear the air fuel ratio initial learning. Refer to Work Procedure.

-

Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0172 detected? Is it difficult to start engine?

YES>>Perform trouble diagnosis for DTC P0172. DTC Description

NO>>GO TO 8.

CHECK HEATED OXYGEN SENSOR 2 GROUND CIRCUIT

-

Turn ignition switch OFF.

-

Disconnect ECM harness connector.

-

Disconnect heated oxygen sensor 2 (HO2S2) harness connector.

-

Check the continuity between HO2S2 harness connector and ECM harness connector.

HO2S2 ECM Continuity Connector Terminal Connector Terminal F67 1 F71 97 Existed -

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES>>GO TO 9.

NO>>Repair or replace malfunctioning part.

CHECK HO2S2 INPUT SIGNAL CIRCUIT

-

Check the continuity between HO2S2 harness connector and ECM harness connector.

HO2S2 ECM Continuity Connector Terminal Connector Terminal F67 2 F71 92 Existed -

Check the continuity between HO2S2 harness connector and ground, or ECM harness connector and ground.

HO2S2 — Continuity Connector Terminal F67 2 Ground Not existed ECM — Continuity Connector Terminal F71 92 Ground Not existed -

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES>>GO TO 10.

NO>>Repair or replace malfunctioning part.

CHECK HEATED OXYGEN SENSOR 2

Refer to Component Inspection.

Is the inspection result normal?

YES>>INSPECTION END

NO>>GO TO 11.

REPLACE HEATED OXYGEN SENSOR 2

Replace heated oxygen sensor 2. Refer to Exploded View.

>>

INSPECTION END

Other materials:

Its Can Communication 3 Circuit

Diagnosis Procedure

CHECK CAN DIAGNOSIS

Check the CAN diagnosis results from CONSULT to see that the ITS CAN

communication 1 circuit and ITS CAN communication 4 circuit have no

malfunction.

Are the ITS CAN communication 1 circuit and ITS CAN communication 4 circuit normal?

YES>>

GO T ...

P06b3 Sensor Power Supply 2

DTC Description

DESCRIPTIONECM supplies a voltage of 5 V to some of the

sensors systematically divided into 3 groups, respectively.

Accordingly, when a short circuit develops in a sensor power source, a

malfunction may occur simultaneously in the sensors belonging to the

same group as the s ...

Rear Final Drive: R145. Removal and Installation

Side Oil Seal

Exploded View

Rear final drive assembly

Side oil seal

Outer circumference

: Always replace after every disassembly.

: Apply gear oil.

Removal and Installation

REMOVALDrain gear oil. Refer to Draining.

Remo ...