Nissan Rogue Service Manual: P2004 intake manifold runner control valve

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| P2004 | TUMBLE CONT/V (Intake manifold runner control stuck open bank 1) | The target angle of intake manifold runner control valve controlled by ECM and the input signal from intake manifold runner control valve position sensor is not in the normal range. |

POSSIBLE CAUSE

- Harness or connectors (Intake manifold runner control valve motor circuit is open or shorted.)

- Intake manifold runner control valve motor

- Intake manifold runner control valve is stuck

FAIL-SAFE

- Traveling control mode (Engine output control)

- Device fix mode

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

TESTING CONDITION:

- Before performing the following procedure, confirm that battery voltage is more than 11 V at idle.

- Always perform the test at a temperature above −7°C (19°F)

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “DATA MONITOR” mode with CONSULT.

- Make sure that “COOLAN TEMP/S” indicates between −7°C (19°F) to

60°C (140°F).

If not, cool engine down or warm engine up until “COOLAN TEMP/S” indicates between −7°C (19°F) to 60°C (140°F). Then go to the following steps.

- Fully release accelerator pedal and wait at least 10 seconds.

- Depress accelerator pedal and wait at least 10 seconds.

- Check 1st trip DTC.

With GST

With GST

Following the procedure “With CONSULT” above.

Is 1st trip DTC detected? YES >> Proceed to EC-420, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

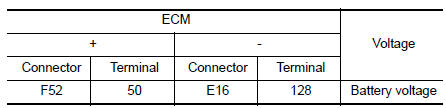

1.CHECK INTAKE MANIFOLD RUNNER CONTROL VALVE MOTOR POWER SUPPLY

- Turn ignition switch ON.

- Check the voltage between ECM harness connector.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

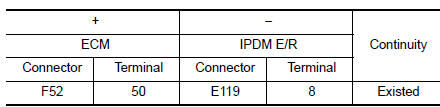

2.CHECK INTAKE MANIFOLD RUNNER CONTROL VALVE MOTOR POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector.

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

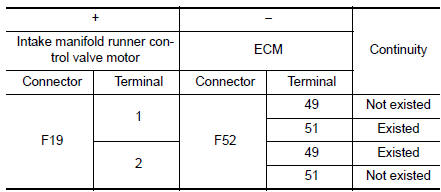

3.CHECK INTAKE MANIFOLD RUNNER CONTROL VALVE MOTOR OUTPUT SIGNAL CIRCUIT

- Disconnect intake manifold runner control valve motor harness connector.

- Check the continuity between intake manifold runner control valve motor harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK INTAKE MANIFOLD RUNNER CONTROL VALVE MOTOR

Check the intake manifold runner control valve motor. Refer to EC-421, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace intake manifold assembly. Refer to EM-26, "Removal and Installation".

5.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> INSPECTION END

Component Inspection

1.CHECK INTAKE MANIFOLD RUNNER CONTROL VALVE

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “DATA MONITOR” mode with CONSULT.

- Make sure that “COOLAN TEMP/S” indicates between −7°C (19°F) to 60°C

(140°F).

If not, cool engine down or warm engine up until “COOLAN TEMP/S” indicates between −7°C (19°F) to 60°C (140°F). Then go to the following steps.

- Fully release accelerator pedal and make sure that “TUMBLE POS SEN” indicates between 2.8 V to 4.1 V.

- Depress accelerator pedal and make sure that “TUMBLE POS SEN” indicates between 0.2 V to 1.4 V.

- Check 1st trip DTC.

With GST

With GST

Following the procedure “With CONSULT” above.

Is 1st trip DTC detected? YES >> Replace intake manifold assembly. Refer to EM-26, "Removal and Installation".

NO >> GO TO 2.

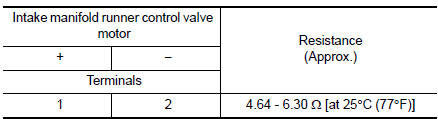

2.CHECK INTAKE MANIFOLD RUNNER CONTROL VALVE MOTOR

- Turn ignition switch OFF.

- Disconnect intake manifold runner control valve motor harness connector.

- Check the resistance between intake manifold runner control valve motor terminals as per the following.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace intake manifold assembly. Refer to EM-26, "Removal and Installation".

P1805 brake switch

P1805 brake switch

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P1805

BRAKE SW/CIRCUIT

(BRAKE SW/CIRCUT)

A stop ...

P2014, P2016, P2017, P2018 intake manifold runner control

valve position sensor

P2014, P2016, P2017, P2018 intake manifold runner control

valve position sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P2014

IN/MANIFOLD RUNNER POS SEN B1

(Intake manifo ...

Other materials:

Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.GET INFORMATION FOR SYMPTOM

Get detailed information from the customer about the symptom (the

condition and the environment when

the incident/malfunction occurs).

Check operation condition of the ...

Preparation

Special Service Tool

The actual shape of the tools may differ from those tools illustrated here.

Tool number

(TechMate No.)

Tool nam

Description

—

(J-50190)

Signal Tech II

Activate and display TPMS transmitter IDs

Display tire ...

None of the power windows can be operated using any

switch

Diagnosis Procedure

1.CHECK BCM POWER SUPPLY AND GROUND CIRCUIT

Check BCM power supply and ground circuit.

Refer to BCS-68, "Diagnosis Procedure" (with Intelligent Key system) or BCS-128,

"Diagnosis Procedure"

(without Intelligent Key system).

Is the inspection result ...