Nissan Rogue Service Manual: P0715 input speed sensor A

DTC Description

DTC DETECTION LOGIC

| DTC | CONSULT screen terms (Trouble diagnosis content) | DTC detection condition |

| P0715 | INPUT SPEED SENSOR A (Input/Turbine Speed Sensor A Circuit) | When 1 is satisfied and any of 2, 3 or 4 is satisfied:

|

POSSIBLE CAUSE

- Harness or connector (Primary speed sensor circuit is open or shorted)

- Primary speed sensor

FAIL-SAFE

- Start is slow

- Acceleration is slow

- Lock-up is not performed

DTC CONFIRMATION PROCEDURE

CAUTION: Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

- Start the engine.

- Drive the vehicle.

- Maintain the following conditions for 10 seconds or more.

Selector lever : “D” POSITION

Engine speed : 1,200 rpm or more

Vehicle speed : 40 km/h (25 MPH) or more

- Stop the vehicle.

- Check the first trip DTC.

Is “P0715” detected? YES >> Go to TM-126, "Diagnosis Procedure".

NO-1 >> To check malfunction symptom before repair: Refer to GI-41, "Intermittent Incident".

NO-2 >> Confirmation after repair: INSPECTION END

Diagnosis Procedure

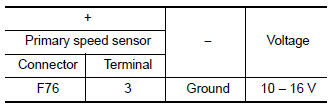

1.CHECK PRIMARY SPEED SENSOR POWER CIRCUIT

- Turn ignition switch OFF.

- Disconnect primary speed sensor connector.

- Turn ignition switch ON.

- Check voltage between primary speed sensor harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 6.

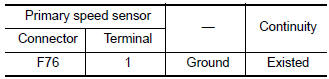

2.CHECK PRIMARY SPEED SENSOR GROUND CIRCUIT

Check continuity between primary speed sensor harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace malfunctioning parts.

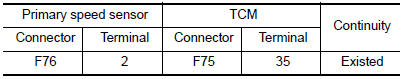

3.CHECK CIRCUIT BETWEEN PRIMARY SPEED SENSOR AND TCM (PART 1)

- Turn ignition switch OFF.

- Disconnect TCM connector.

- Check continuity between primary speed sensor harness connector terminal and TCM harness connector terminal.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace malfunctioning parts.

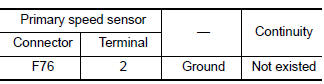

4.CHECK CIRCUIT BETWEEN PRIMARY SPEED SENSOR AND TCM (PART 2)

Check continuity between primary speed sensor harness connector terminal and ground.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace malfunctioning parts.

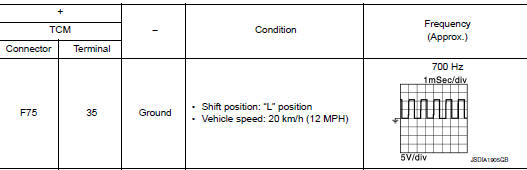

5.CHECK TCM INPUT SIGNALS

- Connect all of disconnected connectors.

- Lift the vehicle.

- Start the engine.

- Check frequency of primary speed sensor.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace primary speed sensor. Refer to TM-208, "Removal and Installation".

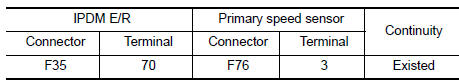

6.CHECK CIRCUIT BETWEEN IPDM E/R AND PRIMARY SPEED SENSOR

- Turn ignition switch OFF.

- Disconnect IPDM E/R connector.

- Check continuity between IPDM E/R harness connector terminal and primary speed sensor harness connector terminal.

Is the check result normal? YES >> GO TO 7.

NO >> Repair or replace malfunctioning parts.

7.DETECT MALFUNCTIONING ITEMS

Check the following items:

- Open circuit or short circuit in harness between ignition switch and IPDM E/R. Refer to PG-15, "Wiring Diagram — Ignition Power Supply —".

- Short circuit in harness between IPDM E/R harness connector terminal 70 and primary speed sensor harness connector terminal 3.

- 10A fuse (No.46, located in the IPDM E/R). Refer to PG-68, "IPDM E/R Terminal Arrangement".

- IPDM E/R

Is the check result normal? YES >> INSPECTION END

NO >> Repair or replace malfunctioning parts.

P0713 transmission fluid temperature sensor A

P0713 transmission fluid temperature sensor A

DTC Description

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P0713

FLUID TEMP SENSOR A

(Transmission Fluid Temperat ...

P0717 input speed sensor A

P0717 input speed sensor A

DTC Description

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P0717

INPUT SPEED SENSOR A

(Input/Turbine Speed Sensor ...

Other materials:

Glass lid

Exploded View

Panoramic roof glass

Glass lid

Side trim covers (LH/RH)

Front drain hose (LH/RH)

Moonroof motor assembly

Sunshade motor assembly

Moonroof front bracket (LH/RH)

Moonroof rear bracket (LH/RH)

Rear drain hose (LH/RH)

Moonroof unit assembly ...

Symptom diagnosis

COMBINATION SWITCH SYSTEM SYMPTOMS

Symptom Table

Perform the data monitor of CONSULT to check for any malfunctioning

item.

Check the malfunction combinations.

Identify the malfunctioning part from the agreed combination and repair

or replace the part.

NORMAL OPERA ...

Warning/indicator lights and audible reminders

Anti-lock Braking System (ABS)

warning light

Brake warning light

Charge warning light

Low tire pressure warning light

Low windshield washer fluid warning light (if so

equipped)

Master warning light

Power s ...