Nissan Rogue Service Manual: P0340 CMP sensor (phase)

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting cond |

| P0340 | CMP SEN/CIRC-B1 (Camshaft position sensor ″A″ circuit bank 1 or single sensor) |

|

POSSIBLE CAUSE

- Harness or connectors (Camshaft position sensor circuit is open or shorted.)

- Camshaft position sensor

- Camshaft (Intake)

- Starter motor

- Starting system circuit

- Dead (Weak) battery

- Sensor power supply 2 circuit

FAIL-SAFE

Not applicable

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION: Before performing the following procedure, confirm that battery voltage is more than 10.5 V with ignition switch ON.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE-1

- Start engine and let it idle for at least 5 seconds.

If engine does not start, crank engine for at least 2 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-298, "Diagnosis Procedure".

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE-2

- Maintaining engine speed at more than 800 rpm for at least 5 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-298, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK STARTING SYSTEM

Turn ignition switch to START position.

Does the engine turn over? Does the starter motor operate?

YES >> GO TO 2.

NO >> Check starting system (Refer to STR-11, "Work Flow (With GR8-1200 NI)" or STR-15, "Work Flow (Without GR8-1200 NI)").

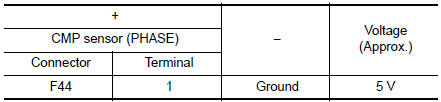

2.CHECK CAMSHAFT POSITION (CMP) SENSOR (PHASE) POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect camshaft position (CMP) sensor (PHASE) harness connector.

- Turn ignition switch ON.

- Check the voltage between CMP sensor (PHASE) harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK SENSOR POWER SUPPLY 2 CIRCUIT

Perform EC-484, "Diagnosis Procedure".

Is inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

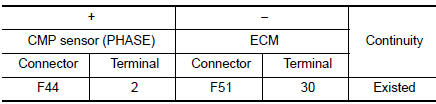

4.CHECK CMP SENSOR (PHASE) GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between CMP sensor (PHASE) harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

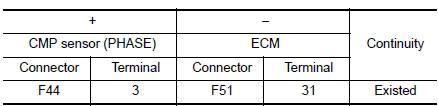

5.CHECK CMP SENSOR (PHASE) INPUT SIGNAL CIRCUIT

- Disconnect ECM harness connector.

- Check the continuity between CMP sensor (PHASE) harness connector and ECM harness connector

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

6.CHECK CAMSHAFT POSITION SENSOR (PHASE)

Check the camshaft position sensor (PHASE). Refer to EC-300, "Component Inspection (Camshaft position sensor)".

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace camshaft position sensor (PHASE). Refer to EM-64, "Removal and Installation".

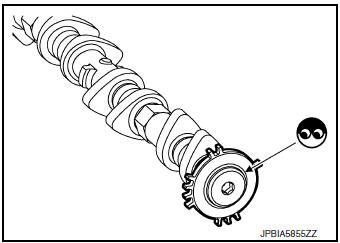

7.CHECK CAMSHAFT (INT)

Check the following.

- Accumulation of debris to the signal plate of camshaft rear end

- Chipping signal plate of camshaft rear end

Is the inspection result normal? YES >> GO TO 8.

NO >> Remove debris and clean the signal plate of camshaft rear end or replace camshaft. Refer to EM-64, "Removal and Installation".

8.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> INSPECTION END

Component Inspection (Camshaft position sensor)

1.CHECK CAMSHAFT POSITION SENSOR (PHASE)-1

- Turn ignition switch OFF.

- Loosen the fixing bolt of the sensor.

- Disconnect camshaft position sensor (PHASE) harness connector.

- Remove the sensor.

- Visually check the sensor for chipping.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace camshaft position sensor (PHASE).

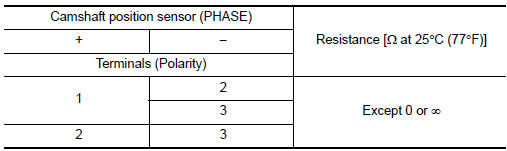

2.CHECK CAMSHAFT POSITION SENSOR (PHASE)-2

Check the resistance camshaft position sensor (PHASE) terminals as per the following.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace camshaft position sensor (PHASE). Refer to EM-64, "Removal and Installation".

P0335 CKP sensor (POS)

P0335 CKP sensor (POS)

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting conditio

P0335

CKP SEN/CIRCUIT

(Crankshaft position sensor & ...

P0420 three way catalyst function

P0420 three way catalyst function

DTC Description

DTC DETECTION LOGIC

The ECM monitors the switching frequency ratio of air fuel ratio (A/F)

sensor 1 and heated oxygen sensor 2.

A three way catalyst (manifold) with high oxygen s ...

Other materials:

Rocker cover

Oil filler cap

Rocker cover

Rocker cover gasket

Refer to INSTALLATION

Engine front

Removal and Installation

REMOVAL

Remove intake manifold. Refer to EM-26, "Removal and

Installation".

Remove wheel and tire (RH) using a power to ...

The low washer fluid warning continues displaying, or

does not display

Description

The warning is still displayed even after washer fluid is added.

The warning is not displayed even though the washer tank is empty.

Diagnosis Procedure

1.CHECK WASHER FLUID LEVEL SWITCH SIGNAL CIRCUIT

Check the washer fluid level switch signal circuit. Refer to MWI-71,

" ...

Oil

Description

MAINTENANCE OF OIL LEVEL

The compressor oil is circulating in the system together with the

refrigerant. It is necessary to fill compressor

with oil when replacing A/C system parts or when a large amount of refrigerant

leak is detected. It is important

to always maintain oil level ...