Nissan Rogue Service Manual: P0327, P0328 KS

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| P0327 | KNOCK SEN/CIRC-B1 (Knock sensor 1 circuit low bank 1 or single sensor) | An excessively low voltage from the knock sensor is sent to ECM. |

| P0328 | KNOCK SEN/CIRC-B1 (Knock sensor 1 circuit high bank 1 or single sensor) | An excessively high voltage from the knock sensor is sent to ECM |

POSSIBLE CAUSE

- Harness or connectors (Knock sensor circuit is open or shorted.)

- Knock sensor

FAIL-SAFE

Not applicable

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION: Before performing the following procedure, confirm that battery voltage is more than 10 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and run it for at least 5 seconds at idle speed.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-293, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

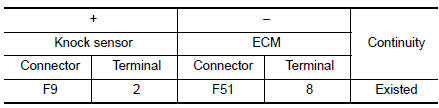

1.CHECK KNOCK SENSOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect knock sensor harness connector.

- Disconnect ECM harness connector.

- Check the continuity between knock sensor harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace error-detected parts.

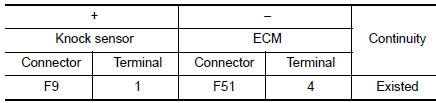

2.CHECK KNOCK SENSOR INPUT SIGNAL CIRCUIT

- Check the continuity between knock sensor harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK KNOCK SENSOR

Check the knock sensor. Refer to EC-294, "Component Inspection".

Is the inspection result normal? YES >> GO TO 4.

NO >> Replace knock sensor. Refer to EM-92, "Exploded View".

4.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> INSPECTION END

Component Inspection

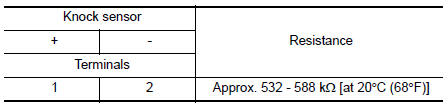

1.CHECK KNOCK SENSOR

- Turn ignition switch OFF.

- Disconnect knock sensor harness connector.

- Check resistance between knock sensor terminals as per the following.

NOTE: It is necessary to use an ohmmeter which can measure more than 10 MΩ.

CAUTION: Do not use any knock sensors that have been dropped or physically damaged. Use only new ones. Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace knock sensor. Refer to EM-92, "Exploded View".

P0300, P0301, P0302, P0303, P0304 misfire

P0300, P0301, P0302, P0303, P0304 misfire

DTC Description

DTC DETECTION LOGIC

When a misfire occurs, engine speed will fluctuate. If the engine speed

fluctuates enough to cause the crankshaft

position (CKP) sensor (POS) signal to vary, E ...

P0335 CKP sensor (POS)

P0335 CKP sensor (POS)

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting conditio

P0335

CKP SEN/CIRCUIT

(Crankshaft position sensor & ...

Other materials:

Child safety

WARNINGDo not allow children to play with the seat

belts. Most seating positions are

equipped with Automatic Locking Retractor

(ALR) mode seat belts. If the seat belt

becomes wrapped around a child’s neck

with the ALR mode activated, the child can

be seriously injured or k ...

Interior room lamp control circuit

Description

Controls each interior room lamp (ground side) by PWM signal.

NOTE:

PWM signal control period is approximately 250 Hz (in the gradual

brightening/dimming).

Component Function Check

CAUTION:

Before performing the diagnosis, check that the following is normal.

Interior ro ...

Sensor power supply2 circuit

Description

ECM supplies a voltage of 5 V to some of the sensors systematically divided

into 2 groups, respectively.

Accordingly, when a short circuit develops in a sensor power source, a

malfunction may occur simultaneously

in the sensors belonging to the same group as the short-circuited ...