Nissan Rogue Service Manual: P0075 intake valve timing control

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| P0075 | INT/V TIM V/CIR-B1 (Intake valve control solenoid circuit bank 1) |

|

POSSIBLE CAUSE

- Harness or connectors

- Intake valve timing control solenoid valve circuit is open or shorted.

- Intake valve timing intermediate lock control solenoid valve circuit is open or shorted.

- Intake valve timing control solenoid valve

- Intake valve timing intermediate lock control solenoid valve

FAIL-SAFE

Not applicable

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and let it idle for 5 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-191, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

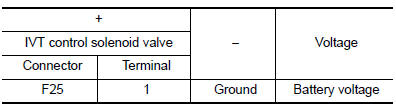

1.CHECK INTAKE VALVE TIMING (IVT) CONTROL SOLENOID VALVE POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect IVT control solenoid valve harness connector.

- Turn ignition switch ON.

- Check the voltage between intake valve timing control solenoid valve harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

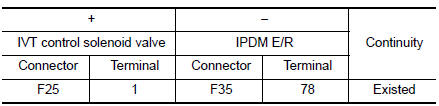

2.CHECK IVT CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect IPDM E/R harness connector.

- Check the continuity between IVT control solenoid valve harness connector and IPDM E/R harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

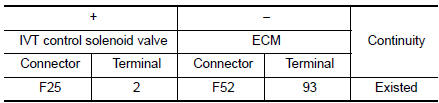

3.CHECK IVT CONTROL SOLENOID VALVE GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between IVT control solenoid valve harness connector and ECM harness connector.

- Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK IVT CONTROL SOLENOID VALVE

Check the IVT control solenoid valve. Refer to EC-193, "Component Inspection (IVT Control Solenoid Valve)".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace IVT control solenoid valve. Refer to EM-44, "Exploded View".

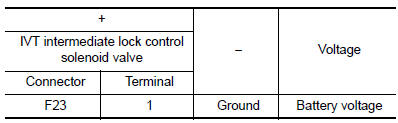

5.CHECK IVT INTERMEDIATE LOCK CONTROL SOLENOID VALVE POWER SUPPLY

- Disconnect IVT intermediate lock control solenoid valve harness connector.

- Turn ignition switch ON.

- Check the voltage between IVT intermediate lock control solenoid valve harness connector and ground.

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 6.

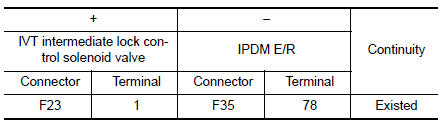

6.CHECK IVT INTERMEDIATE LOCK CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect IPDM E/R harness connector.

- Check the continuity between IVT intermediate lock control solenoid valve harness connector and IPDM E/R harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

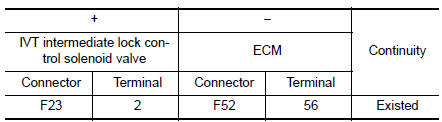

7.CHECK IVT INTERMEDIATE LOCK CONTROL SOLENOID VALVE GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between IVT intermediate lock control solenoid valve harness connector and ECM harness connector.

- Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair or replace error-detected parts.

8.CHECK IVT INTERMEDIATE LOCK CONTROL SOLENOID VALVE

Check the IVT intermediate lock control solenoid valve. Refer to EC-194, "Component Inspection (IVT Intermediate Lock Control Solenoid Valve)".

Is the inspection result normal? YES >> GO TO 9.

NO >> Replace IVT intermediate lock control solenoid valve. Refer to EM-64, "Exploded View".

9.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> INSPECTION END

Component Inspection (IVT Control Solenoid Valve)

1.CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE-I

- Turn ignition switch OFF.

- Disconnect intake valve timing control solenoid valve harness connector.

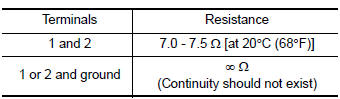

- Check resistance between intake valve timing control solenoid valve terminals as follows.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace intake valve timing control solenoid valve. Refer to EM-44, "Exploded View".

2.CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE-II

- Remove intake valve timing control solenoid valve. Refer to EM-44, "Exploded View".

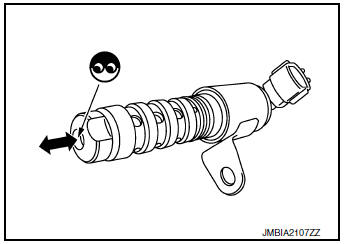

- Provide 12 V DC between intake valve timing control solenoid valve terminals 1 and 2, and then interrupt it. Make sure that the plunger moves as shown in the figure.

CAUTION: Do not apply 12 V DC continuously for 5 seconds or more.

Doing so may result in damage to the coil in intake valve timing control solenoid valve.

NOTE: Always replace O-ring when intake valve timing control solenoid valve is removed.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace intake valve timing control solenoid valve. Refer to EM-44, "Exploded View".

Component Inspection (IVT Intermediate Lock Control Solenoid Valve)

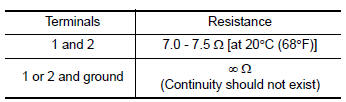

1.CHECK INTAKE VALVE TIMING INTERMEDIATE LOCK CONTROL SOLENOID VALVE-I

- Turn ignition switch OFF.

- Disconnect intake valve timing intermediate lock control solenoid valve harness connector.

- Check resistance between intake valve timing intermediate lock control solenoid valve terminals as follows.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace intake valve timing intermediate lock control solenoid valve. Refer to EM-44, "Exploded View".

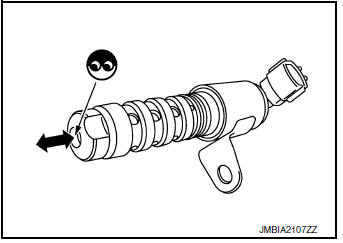

2.CHECK INTAKE VALVE TIMING INTERMEDIATE LOCK CONTROL SOLENOID VALVE-II

- Remove intake valve timing intermediate lock control solenoid valve. Refer to EM-44, "Exploded View".

- Provide 12 V DC between intake valve timing intermediate lock

control solenoid valve terminals 1 and 2, and then interrupt it.

Make sure that the plunger moves as shown in the figure.

CAUTION: Do not apply 12 V DC continuously for 5 seconds or more.

Doing so may result in damage to the coil in intake valve timing intermediate lock control solenoid valve.

NOTE: Always replace O-ring when intake valve timing intermediate lock control solenoid valve is removed.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace intake valve timing intermediate lock control solenoid valve. Refer to EM-44, "Exploded View".

P0037, P0038 HO2S2 heater

P0037, P0038 HO2S2 heater

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0037

HO2S2 HTR (B1)

(HO2S heater control circuit ...

P0078 EVT control solenoid valve

P0078 EVT control solenoid valve

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condit

P0078

EX V/T ACT/CIRC-B1

(Exhaust valve control solen ...

Other materials:

P2127, P2128 APP sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P2127

APP SEN 2/CIRC

(Throttle/pedal position sensor/switch ″E″

circuit low)

An excessively low voltage from the APP sensor 2 is sen ...

The low washer fluid warning continues displaying, or

does not display

Description

The warning is still displayed even after washer fluid is added.

The warning is not displayed even though the washer tank is empty.

Diagnosis Procedure

1.CHECK WASHER FLUID LEVEL SWITCH SIGNAL CIRCUIT

Check the washer fluid level switch signal circuit. Refer to MWI-71,

" ...

Sun visors

Sun visors

To block glare from the front, swing down the

main sun visor.

To block glare from the side, remove the

main sun visor from the center mount and

swing the visor to the side.

To extend the sun visor, slide in or out as

needed.

CAUTION

Do not ...