Nissan Rogue Service Manual: Overdrive control switch

Component Function Check

1.CHECK O/D OFF INDICATOR LAMP FUNCTION

Check O/D OFF indicator lamp turns ON for approx. 2 seconds when ignition switch turns ON.

Is the inspection results normal? YES >> GO TO 2.

NO >> Go to TM-181, "Diagnosis Procedure".

2.CHECK OVERDRIVE CONTROL SWITCH FUNCTION

- Shift the selector lever to “D” position.

- Check that O/D OFF indicator lamp turns ON/OFF when overdrive control switch is operated.

Is the inspection results normal? YES >> INSPECTION END

NO >> Go to TM-178, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK OVERDRIVE CONTROL SWITCH CIRCUIT

- Turn ignition switch OFF.

- Disconnect CVT shift selector connector.

- Turn ignition switch ON.

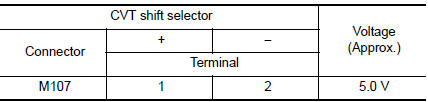

- Check voltage between CVT shift selector harness connector terminals.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 4.

2.CHECK CVT SHIFT SELECTOR CIRCUIT

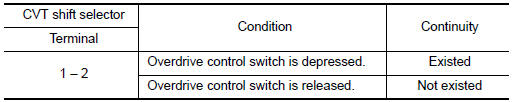

Check continuity between CVT shift selector harness connector terminals.

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 3.

3.CHECK OVERDRIVE CONTROL SWITCH

Check overdrive control switch. Refer to TM-179, "Component Inspection".

Is the inspection result normal? YES >> Repair CVT shift selector assembly. Refer to TM-194, "Removal and Installation".

NO >> Replace selector lever knob. Refer to TM-194, "Removal and Installation".

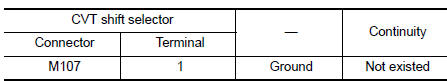

4.CHECK GROUND CIRCUIT

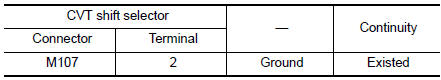

Check continuity between CVT shift selector harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace malfunctioning parts.

5.CHECK CIRCUIT BETWEEN CVT SHIFT SELECTOR AND COMBINATION METER (PART 1)

- Turn ignition switch OFF.

- Disconnect combination meter connector.

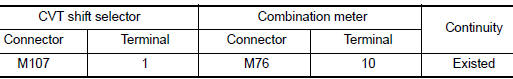

- Check continuity between CVT shift selector harness connector terminal and combination meter harness connector terminal.

the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace malfunctioning parts.

6.CHECK CIRCUIT BETWEEN CVT SHIFT SELECTOR AND COMBINATION METER (PART 2)

Check continuity between CVT shift selector harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair or replace malfunctioning parts.

7.CHECK COMBINATION METER INPUT/OUTPUT SIGNAL

- Connect all of disconnected connectors.

- Turn ignition switch ON.

- Select “Data Monitor” in “METER/M&A”.

- Select “O/D OFF SW”.

- Check that “O/D OFF SW” turns ON/OFF when overdrive control switch is operated. Refer to MWI-24, "Reference Value".

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-41, "Intermittent Incident".

NO >> Replace combination meter. Refer to MWI-82, "Removal and Installation".

Component Inspection

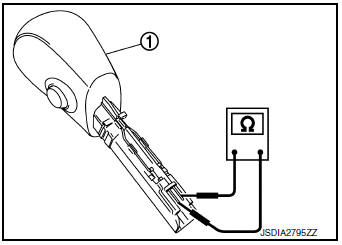

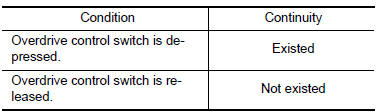

1.CHECK OVERDRIVE CONTROL SW

Check continuity between wires of shift selector knob 1.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace shift selector knob. Refer to TM-194, "Removal and Installation".

Main power supply and ground circuit

Main power supply and ground circuit

Diagnosis Procedure

1.CHECK TCM POWER CIRCUIT (PART 1)

Turn ignition switch OFF.

Disconnect TCM connector.

Check voltage between TCM harness connector terminals and ground.

...

O/D off indicator lamp

O/D off indicator lamp

Component Function Check

1.CHECK O/D OFF INDICATOR LAMP FUNCTION

Check O/D OFF indicator lamp turns ON for approx. 2 seconds when ignition

switch turns ON.

Is the inspection results normal?

YE ...

Other materials:

Power supply and ground circuit

WITH INTELLIGENT KEY SYSTEM

WITH INTELLIGENT KEY SYSTEM : Diagnosis Procedure

Regarding Wiring Diagram information, refer to BCS-50, "Wiring Diagram".

1. CHECK FUSE

Check that the following fuse is not blown.

Terminal No.

Signal name

Fuse No.

161

BCM power sup ...

Seats

WARNING

Do not ride in a moving vehicle when

the seatback is reclined. This can be

dangerous. The shoulder belt will not

be against your body. In an accident,

you could be thrown into it and receive

neck or other serious injuries. You

could also slide under ...

Front bumper

Exploded View

Front bumper fascia side

bracket (RH)

Front bumper reinforcement

support (RH)

Front bumper reinforcement

Front energy absorber

Front lower grille

Front fog lamp (RH) (if equipped)

Front bumper fascia

Front bumper fascia finisher

(RH) (if equipped)

...