Nissan Rogue Service Manual: Front washer nozzle and tube

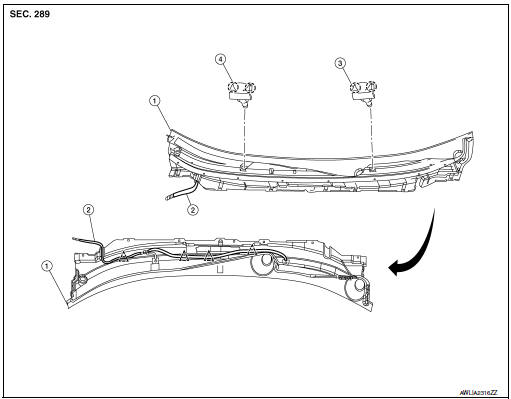

Exploded View

- Cowl top cover

- Front washer tube

- Front washer nozzle (LH)

- Front washer nozzle (RH)

Pawl

Pawl

Clip

Clip

Exploded View

- Cowl top cover

- Front washer tube

Clip

Clip

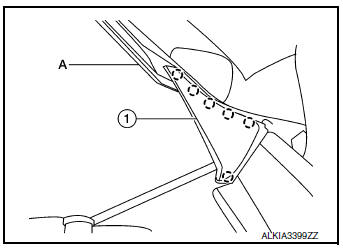

Removal and Installation - Front Washer Nozzle

REMOVAL

- Remove front wiper arms (LH/RH). Refer to WW-63, "Removal and Installation".

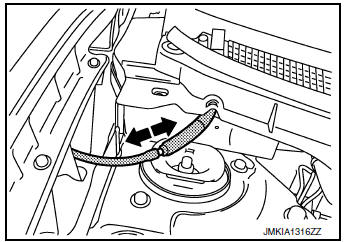

- Release pawls using suitable tool (A) and remove cowl top side

trim cover (1) (LH/RH).

: Pawl

: Pawl

- Disconnect front washer tube connector.

- Release pawls and remove front washer nozzle (LH/RH).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION: Adjust the nozzle spray pattern. Refer to WW-61, "Inspection and Adjustment".

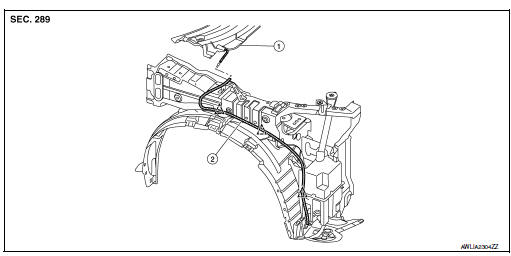

Removal and Installation - Front Washer Tube

REMOVAL

- Disconnect front washer tube connector.

- Remove engine side cover. Refer to EXT-28, "FENDER PROTECTOR : Exploded View".

- Remove engine undercover. Refer to EXT-37, "ENGINE UNDER COVER : Removal and Installation".

- Partially remove fender protector. Refer to EXT-28, "FENDER PROTECTOR : Exploded View".

- Unclip front washer hose and remove.

INSTALLATION

Installation is in the reverse order of removal.

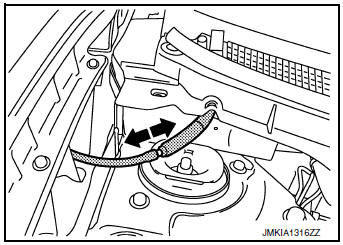

Inspection and Adjustment

WASHER TUBE INSPECTION

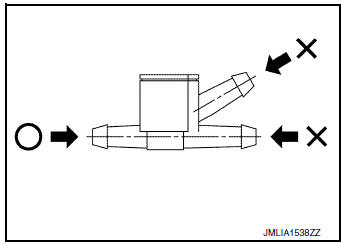

Check that air can pass through the check valve splitter by blowing into the check valve splitter and that air cannot flow in the opposite direction.

O: Air can flow

X: Air cannot flow

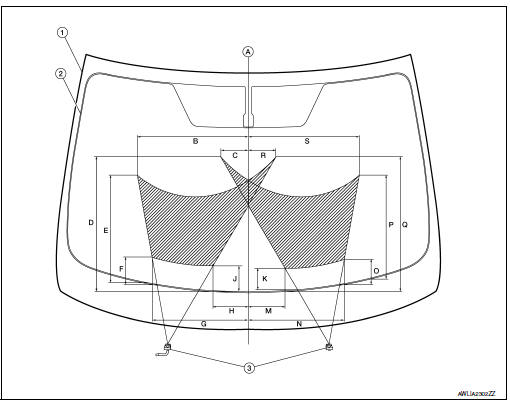

ADJUSTMENT

If operating properly, spray positions should match the positions shown. If spray positions do not match, confirm the rear washer nozzle is properly seated and working properly. If the spray positions still do not match as shown, then replace the front washer nozzle. Refer to WW-60, "Removal and Installation - Front Washer Nozzle"

- Windshield glass

- Black printed area line

- Front washer nozzle (LH/RH)

- Center line

- 409 mm (16.10 in)

- 103 mm (4.06 in)

- 497 mm (19.57 in)

- 398 mm (15.67 in)

- 100 mm (3.94 in)

- 356 mm (14.02 in)

- 127 mm (5.00 in)

- 93 mm (3.66 in)

- 80 mm (3.15 in)

- 133 mm (5.24 in)

- 354 mm (13.94 in)

- 90 mm (3.54 in)

- 380 mm (14.96 in)

- 496 mm (19.53 in)

- 103 mm (4.06 in)

- 409 mm (16.10 in)

Washer fluid level switch

Washer fluid level switch

Removal and Installation

The washer fluid level switch is serviced as a part of the washer tank. Refer

to WW-56, "Removal and Installation". ...

Front wiper arm

Front wiper arm

Exploded View

Front wiper blade (RH)

Front wiper arm (RH)

Front wiper arm cover

Front wiper drive assembly

Front wiper arm (LH)

Front wiper blade (LH)

Removal ...

Other materials:

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

...

Component parts

Component Parts Location

View of cowl area (with cowl top cover

removed)

RH front of vehicle (with front

bumper fascia removed)

View with back door finisher removed

No.

Component

Function

1

Combination switch

(Wiper and washer switch)

Ref ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

...