Nissan Rogue Service Manual: Encoder circuit

Description

Detects condition of the front power window motor LH operation and transmits to main power window and door lock/unlock switch as pulse signal.

Component Function Check

1.CHECK ENCODER OPERATION

Check front driver side door glass perform AUTO open/close operation normally when main power window and door lock/unlock switch.

Is the inspection result normal? YES >> Encoder operation is OK.

NO >> Refer to PWC-45, "Diagnosis Procedure"

Diagnosis Procedure

Encoder Circuit Check

1.CHECK ENCODER OPERATION

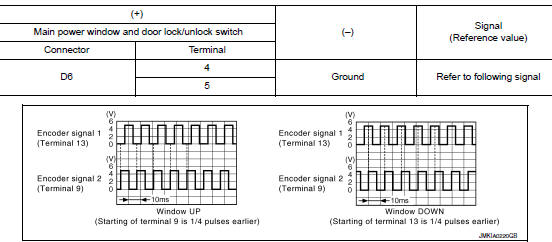

- Turn ignition switch ON.

- Check signal between main power window and door lock/unlock switch harness connector and ground with oscilloscope.

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 2.

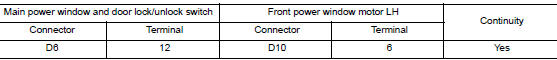

2.CHECK ENCORDER SIGNAL CIRCUIT

- Turn ignition switch OFF.

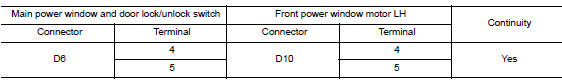

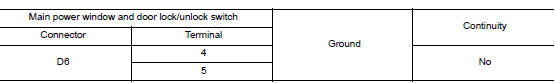

- Disconnect main power window and door lock/unlock switch connector and front power window motor LH connector.

- Check continuity between main power window and door lock/unlock switch harness connector and front power window motor LH harness connector.

- Check continuity between main power window and door lock/unlock switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK ENCORDER POWER SUPPLY CIRCUIT

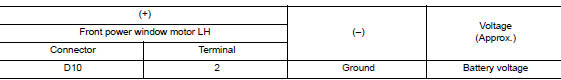

- Connect main power window and door lock/unlock switch connector.

- Turn ignition switch ON.

- Check voltage between front power window motor LH harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 5.

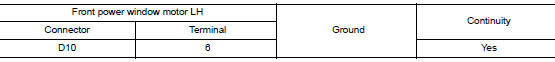

4.CHECK GROUND CIRCUIT

- Turn ignition switch OFF.

- Check continuity between front power window motor LH harness connector and ground.

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 6.

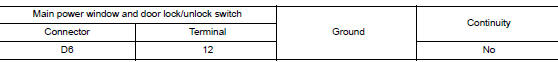

5.CHECK HARNESS CONTINUITY 1

- Turn ignition switch OFF.

- Check continuity between main power window and door lock/unlock switch harness connector and front power window motor LH harness connector.

- Check continuity between main power window and door lock/unlock switch harness connector and ground.

Is the inspection result normal? YES >> Replace main power window and door lock/unlock switch. Refer to PWC-65, "Removal and Installation".

NO >> Repair or replace harness.

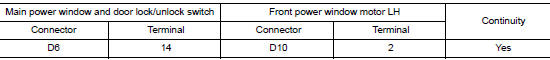

6.CHECK HARNESS CONTINUITY 2

- Disconnect main power window and door lock/unlock switch connector.

- Check continuity between main power window and door lock/unlock switch harness connector and front power window motor LH harness connector.

Is the inspection result normal? YES >> Replace main power window and door lock/unlock switch. Refer to PWC-65, "Removal and Installation".

NO >> Repair or replace harness.

7.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> Inspection End.

Power window motor

Power window motor

DRIVER SIDE

DRIVER SIDE : Description

Door glass moves UP/DOWN by receiving the signal from main power window and

door lock/unlock switch.

DRIVER SIDE : Component Function Check

1. CHECK FRONT P ...

Power window relay

Power window relay

Description

Power is supplied to the main power window and door lock/unlock with BCM

control.

Component Function Check

1. CHECK POWER WINDOW RELAY POWER SUPPLY CIRCUIT

Check that an operation no ...

Other materials:

Flexible seating

WARNING

Never allow anyone to ride in the cargo

area or on the rear seats when they are

in the fold-down position. In a collision,

people riding in these areas without

proper restraints are more likely to be

seriously injured or killed.

Do not allow peo ...

Inside mirror

Exploded View

MANUAL ANTI-DAZZLING

Windshield glass

Mirror base

Inside mirror

AUTO ANTI-DAZZLING

Windshield glass

Mirror base

Inside mirror

Inside mirror finisher

Harness connector

Bolt

Removal and Installation

MANUAL ANTI-DAZZLING

Removal ...

B0010, B0011 passenger airbag module

DTC Logic

DTC DETECTION LOGIC

CONSULT name

DTC

DTC detecting condition

Repair order

ASSIST AIRBAG MODULE CIRCUIT

[OPEN]

B0010

Front passenger air bag module circuit

(AS1) is open.

Refer to SRC-49, "Diagnosis Procedure".

ASS ...