Nissan Rogue Service Manual: DTC/circuit diagnosis

U1000 CAN COMM CIRCUIT

WITH INTELLIGENT KEY

WITH INTELLIGENT KEY : Description

Refer to LAN-8, "System Description".

WITH INTELLIGENT KEY : DTC Logic

DTC DETECTION LOGIC

NOTE: U1000 can be set if a module harness was disconnected and reconnected, perhaps during a repair. Confirm that there are actual CAN diagnostic symptoms and a present DTC by performing the Self Diagnostic Result procedure.

|

CONSULT Display |

DTC Detection Condition |

Possible cause |

| CAN COMM CIRCUIT [U1000] | When any listed module cannot communicate with CAN communication signal continuously for 2 seconds or more with ignition switch ON. | In CAN communication system, any item (or items)

of the following listed below is malfunctioning.

|

WITH INTELLIGENT KEY : Diagnosis Procedure

1. PERFORM SELF DIAGNOSTIC

- Turn ignition switch ON and wait for 2 second or more.

- Check “SELF- DIAG RESULTS”.

Is “CAN COMM CIRCUIT” displayed? YES >> Perform CAN Diagnosis as described in DIAGNOSIS section of CONSULT Operation Manual.

NO >> Refer to GI-41, "Intermittent Incident".

WITHOUT INTELLIGENT KEY

WITHOUT INTELLIGENT KEY : Description

Refer to LAN-8, "System Description".

WITHOUT INTELLIGENT KEY : DTC Logic

DTC DETECTION LOGIC

NOTE: U1000 can be set if a module harness was disconnected and reconnected, perhaps during a repair. Confirm that there are actual CAN diagnostic symptoms and a present DTC by performing the Self Diagnostic Result procedure.

|

CONSULT Display |

DTC Detection Condition |

Possible cause |

| CAN COMM CIRCUIT [U1000] | When any listed module cannot communicate with CAN communication signal continuously for 2 seconds or more with ignition switch ON. | In CAN communication system, any item (or items)

of the following listed below is malfunctioning.

|

WITHOUT INTELLIGENT KEY : Diagnosis Procedure

1. PERFORM SELF DIAGNOSTIC

- Turn ignition switch ON and wait for 2 second or more.

- Check “SELF- DIAG RESULTS”.

Is “CAN COMM CIRCUIT” displayed? YES >> Perform CAN Diagnosis as described in DIAGNOSIS section of CONSULT Operation Manual.

NO >> Refer to GI-41, "Intermittent Incident".

U1010 CONTROL UNIT (CAN)

WITH INTELLIGENT KEY

WITH INTELLIGENT KEY : DTC Logic

DTC DETECTION LOGIC

|

CONSULT Display |

DTC Detection Condition |

Possible cause |

| CAN COMM CIRCUIT [U1010] | BCM detected internal CAN communication circuit malfunction. | BCM |

WITH INTELLIGENT KEY : Diagnosis Procedure

1. REPLACE BCM

When DTC U1010 is detected, replace BCM.

>> Replace BCM. Refer to BCS-75, "Removal and Installation".

WITHOUT INTELLIGENT KEY

WITHOUT INTELLIGENT KEY : DTC Logic

DTC DETECTION LOGIC

|

CONSULT Display |

DTC Detection Condition |

Possible cause |

| CAN COMM CIRCUIT [U1010] | BCM detected internal CAN communication circuit malfunction. | BCM |

WITHOUT INTELLIGENT KEY : Diagnosis Procedure

1. REPLACE BCM

When DTC U1010 is detected, replace BCM.

>> Replace BCM. Refer to BCS-135, "Removal and Installation".

B2614 ACC RELAY CIRCUIT

DTC Logic

DTC DETECTION LOGIC

|

CONSULT Display |

DTC Detection Condition |

Possible cause |

| ACC RELAY CIRCUIT [B2614] | An immediate operation of accessory relay-1 is requested by BCM, but there is no response for more than 1 second. |

|

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF DIAGNOSTIC RESULT

- Turn ignition switch to ON, and wait for 1 second or more.

- Check “Self Diagnosis Result” of “BCM” with CONSULT.

Is DTC B2614 detected? YES >> Go to PCS-64, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to PCS-49, "Wiring Diagram".

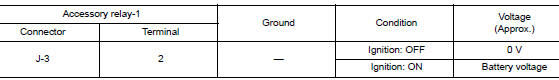

1.CHECK ACCESSORY RELAY-1 CONTROL SIGNAL VOLTAGE

- Remove accessory relay-1.

- Check voltage between accessory relay-1 connector J-3 and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

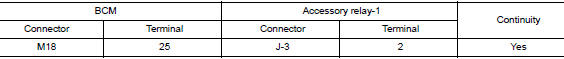

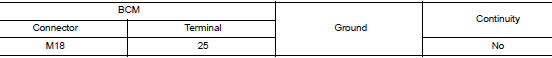

2.CHECK ACCESSORY RELAY-1 CONTROL SIGNAL CIRCUIT

- Turn ignition switch OFF.

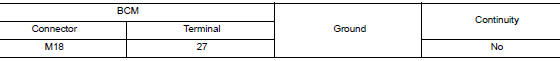

- Disconnect BCM connector M18.

- Check continuity between BCM connector M18 and accessory relay-1 connector J-3.

- Check continuity between BCM connector M18 and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to PCS-76, "Removal and Installation".

NO >> Repair or replace harness or connectors.

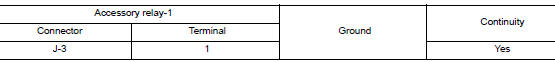

3.CHECK ACCESSORY RELAY-1 GROUND CIRCUIT

Check continuity between accessory relay-1 connector J-3 and ground.

Is the inspection result normal? YES >> Replace accessory relay-1.

NO >> Repair or replace harness or connectors.

B2615 BLOWER RELAY CIRCUIT

DTC Logic

DTC DETECTION LOGIC

|

CONSULT Display |

DTC Detection Condition |

Possible cause |

| BLOWER RELAY CIRCUIT [B2615] | An immediate operation of front blower motor relay is requested by BCM, but there is no response for more than 1 second |

|

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF DIAGNOSTIC RESULT

- Turn ignition switch to ON, and wait for 1 second or more.

- Check “Self Diagnosis Result” of “BCM” with CONSULT.

Is DTC B2615 detected? YES >> Go to PCS-68, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to PCS-49, "Wiring Diagram".

1.CHECK FRONT BLOWER MOTOR RELAY CONTROL SIGNAL VOLTAGE

- Remove front blower motor relay.

- Check voltage between front blower motor relay connector J-4 and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

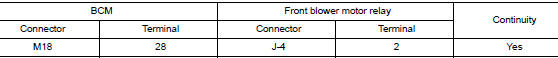

2.CHECK FRONT BLOWER MOTOR RELAY CONTROL SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect BCM connector M18.

- Check continuity between BCM connector M18 and front blower motor relay connector J-4.

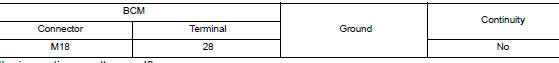

- Check continuity between BCM connector M18 and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to PCS-76, "Removal and Installation".

NO >> Repair or replace harness or connectors.

3.CHECK FRONT BLOWER MOTOR RELAY GROUND CIRCUIT

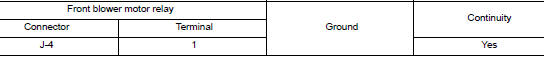

Check continuity between front blower motor relay connector J-4 and ground.

Is the inspection result normal? YES >> Replace front blower motor relay.

NO >> Repair or replace harness or connectors.

B2616 IGNITION RELAY CIRCUIT

DTC Logic

DTC DETECTION LOGIC

|

CONSULT Display |

DTC Detection Condition |

Possible cause |

| IGNITION RELAY CIRCUIT [B2616] | An immediate operation of ignition relay-2 is requested by BCM, but there is no response for more than 1 second. |

|

DTC CONFIRMATION PROCEDURE

1. PERFORM SELF DIAGNOSTIC RESULT

- Turn ignition switch to ON, and wait for 1 second or more.

- Check “Self Diagnosis Result” of “BCM” with CONSULT.

Is DTC B2616 detected? YES >> Refer to PCS-68, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to PCS-49, "Wiring Diagram".

1.CHECK IGNITION RELAY-2 CONTROL SIGNAL VOLTAGE

- Remove ignition relay-2.

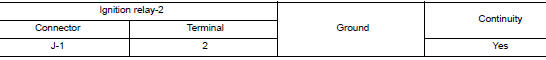

- Check voltage between ignition relay-2 connector J-1 and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

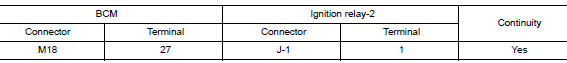

2.CHECK IGNITION RELAY-2 CONTROL SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect BCM connector M18.

- Check continuity between BCM connector M18 and ignition relay-2 connector J-1.

- Check continuity between BCM connector M18 and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to PCS-76, "Removal and Installation".

NO >> Repair or replace harness or connectors.

3.CHECK IGNITION RELAY-2 GROUND CIRCUIT

Check continuity between ignition relay-2 connector J-1 and ground.

Is the inspection result normal? YES >> Replace ignition relay-2.

NO >> Repair or replace harness or connectors.

B261A PUSH-BUTTON IGNITION SWITCH

DTC Logic

DTC DETECTION LOGIC

|

CONSULT Display |

DTC Detection Condition |

Possible cause |

| PUSH-BUTTON IGNITION SWITCH [B261A] | BCM detects a difference of signal for 1 second or

more between the following information:

|

|

DTC CONFIRMATION PROCEDURE

1. PERFORM SELF DIAGNOSTIC RESULT

- Turn ignition switch to ON, and wait for 1 second or more.

- Check “Self Diagnosis Result” of “BCM” with CONSULT.

Is DTC B261A detected? YES >> Refer to PCS-70, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to PCS-49, "Wiring Diagram".

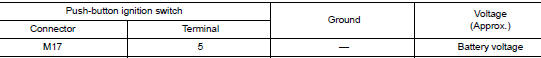

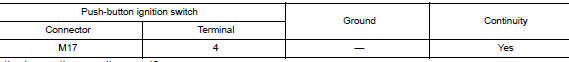

1. CHECK PUSH-BUTTON IGNITION SWITCH OUTPUT SIGNAL (PUSH-BUTTON IGNITION SWITCH)

- Disconnect push-button ignition switch connector.

- Check voltage between push-button ignition switch connector M17 and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 4.

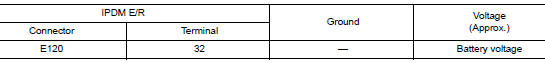

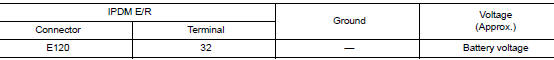

2. CHECK PUSH-BUTTON IGNITION SWITCH OUTPUT SIGNAL (IPDM E/R)

Check voltage between IPDM E/R connector E120 and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace IPDM E/R. Refer to PCS-35, "Removal and Installation".

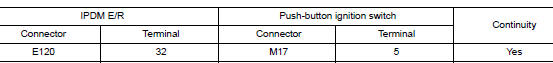

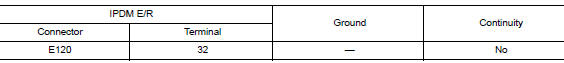

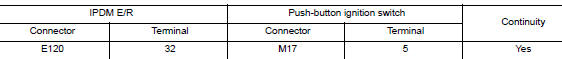

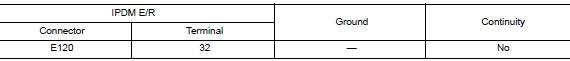

3. CHECK PUSH-BUTTON IGNITION SWITCH CIRCUIT (IPDM E/R)

- Turn ignition switch OFF.

- Disconnect IPDM E/R connector E120 and BCM connector M19.

- Check continuity between IPDM E/R connector E120 and push-button ignition switch connector M17.

- Check continuity between IPDM E/R connector E120 and ground.

Is the inspection result normal? YES >> Refer to GI-41, "Intermittent Incident".

NO >> Repair or replace harness or connectors.

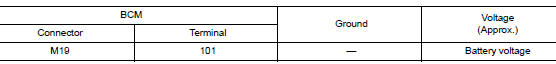

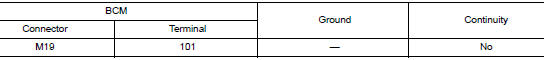

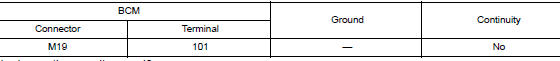

4. CHECK IGNITION SWITCH OUTPUT SIGNAL (BCM)

Check voltage between BCM connector M19 and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace BCM. Refer to PCS-76, "Removal and Installation".

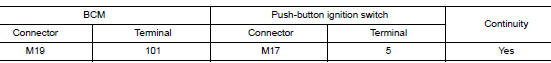

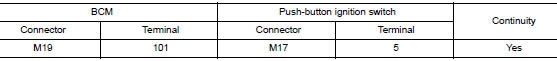

5. CHECK PUSH-BUTTON IGNITION SWITCH CIRCUIT (BCM)

- Turn ignition switch OFF.

- Disconnect BCM connector M19 and IPDM E/R connector E120.

- Check continuity between BCM connector M19 and push-button ignition switch connector M17.

- Check continuity between BCM connector M19 and ground.

Is the inspection result normal? YES >> Refer to GI-41, "Intermittent Incident".

NO >> Repair or replace harness or connectors.

PUSH-BUTTON IGNITION SWITCH

Component Function Check

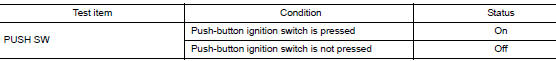

1.CHECK FUNCTION

- Select “PUSH SW” in “Data Monitor” of “BCM” with CONSULT.

- Check the push-button ignition switch signal under the following conditions.

Is the indication normal? YES >> Inspection End.

NO >> Go to PCS-72, "Diagnosis Procedure".

Diagnosis Procedure

Regarding Wiring Diagram information, refer to PCS-49, "Wiring Diagram".

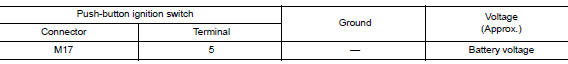

1. CHECK PUSH-BUTTON IGNITION SWITCH OUTPUT SIGNAL (PUSH-BUTTON IGNITION SWITCH)

- Turn ignition switch OFF.

- Disconnect push-button ignition switch connector and IPDM E/R connector E120.

- Check voltage between push-button ignition switch connector M17 and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2. CHECK PUSH-BUTTON IGNITION SWITCH CIRCUIT (BCM)

- Disconnect BCM connector M19.

- Check continuity between BCM connector M19 and push-button ignition switch connector M17.

- Check continuity between BCM connector M19 and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to PCS-76, "Removal and Installation".

NO >> Repair or replace harness or connectors.

3. CHECK IGNITION SWITCH OUTPUT SIGNAL (IPDM E/R)

Check voltage between IPDM E/R connector E120 and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4. CHECK PUSH-BUTTON IGNITION SWITCH CIRCUIT (IPDM E/R)

- Disconnect BCM connector M19.

- Check continuity between IPDM E/R connector E120 and push-button ignition switch connector M17.

- Check continuity between IPDM E/R connector E120 and ground.

Is the inspection result normal? YES >> Replace IPDM E/R. Refer to PCS-35, "Removal and Installation".

NO >> Repair or replace harness or connectors.

5.CHECK PUSH-BUTTON IGNITION SWITCH GROUND CIRCUIT

Check continuity between push-button ignition switch connector M17 and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace harness or connectors.

6.CHECK PUSH-BUTTON IGNITION SWITCH

Refer to PCS-73, "Component Inspection".

Is the inspection result normal? YES >> Refer to GI-41, "Intermittent Incident".

NO >> Replace push-button ignition switch. Refer to PCS-77, "Removal and Installation".

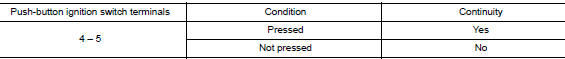

Component Inspection

1.CHECK PUSH-BUTTON IGNITION SWITCH

- Turn ignition switch OFF.

- Disconnect push-button ignition switch connector.

- Check continuity between push-button ignition switch terminals.

Is the inspection result normal? YES >> Inspection End.

NO >> Replace push-button ignition switch.

Basic inspection

Basic inspection

DIAGNOSIS AND REPAIR WORK FLO

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.GET INFORMATION FOR SYMPTOM

Get detailed information from the customer about the symptom (the

condition an ...

Symptom diagnosis

Symptom diagnosis

PUSH-BUTTON IGNITION SWITCH DOES NOT OPERATE

Description

Check that vehicle Operating Conditions are as listed in “Conditions of

Vehicle” below before starting Diagnosis

Procedure. Make sure ...

Other materials:

System description

COMPONENT PARTS

Component Part Location

RH side of engine compartment

RH front of vehicle (view with front

bumper fascia removed)

No.

Component

Description

1

IPDM E/R

Refer to PCS-5, "RELAY CONTROL SYSTEM : System Description".

...

Preparation

Special Service Tools

The actual shape of the tools may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name

Description

—

(J-46534)

Trim Tool Set

Removing trim components

...

Removal and installation

FRONT WHEEL HUB

Exploded View

Disc brake rotor

Nut retainer

Cotter pin

Wheel stud

Steering knuckle

Splash guard

Wheel hub and bearing

Wheel hub lock nut

Removal and Installation

REMOVAL

Remove front wheel and tire using power tool. Refe ...