Nissan Rogue Service Manual: CVT fluid cooler system

Cleaning

Whenever an automatic transaxle is repaired, overhauled, or replaced, the CVT fluid cooler mounted in the radiator must be inspected and cleaned.

Metal debris and friction material, if present, can be trapped or be deposited in the CVT fluid cooler. This debris can contaminate the newly serviced CVT or, in severe cases, can block or restrict the flow of CVT fluid.

In either case, malfunction of the newly serviced CVT may occur.

Debris, if present, may deposit as CVT fluid enters the cooler inlet. It will be necessary to back flush the cooler through the cooler outlet in order to flush out any built up debris.

CVT FLUID COOLER CLEANING PROCEDURE

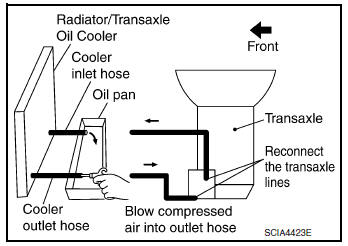

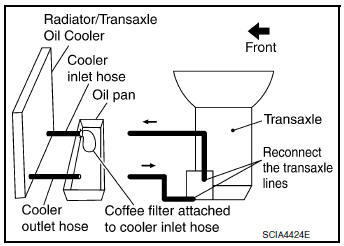

- Position an oil pan under the transaxle's inlet and outlet cooler hoses.

- Identify the inlet and outlet fluid cooler hoses.

- Disconnect the fluid cooler inlet and outlet rubber hoses from the

steel cooler tubes or bypass valve.

NOTE: Replace the cooler hoses if rubber material from the hose remains on the tube fitting.

- Allow any CVT fluid that remains in the cooler hoses to drain into the oil pan.

- Insert the extension adapter hose of a can of Transmission Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler outlet hose.

CAUTION:

- Wear safety glasses and rubber gloves when spraying the Transmission Cooler Cleaner.

- Spray Transmission Cooler Cleaner only with adequate ventilation.

- Avoid contact with eyes and skin.

- Never breath vapors or spray mist.

- Hold the hose and can as high as possible and spray Transmission Cooler Cleaner in a continuous stream into the cooler outlet hose until CVT fluid flows out of the cooler inlet hose for 5 seconds.

- Insert the tip of an air gun into the end of the cooler outlet hose.

- Wrap a shop rag around the air gun tip and end of the cooler outlet hose.

- Blow compressed air regulated to 5 to 9 kg/cm2 (70 to 130 psi) through the cooler outlet hose for 10 seconds to force out any remaining CVT fluid.

- Repeat steps 5 through 9 three additional times.

- Position an oil pan under the banjo bolts that connect the CVT fluid cooler steel lines to the transaxle.

- Remove the banjo bolts.

- Flush each steel line from the cooler side back toward the transaxle by spraying Transmission Cooler Cleaner in a continuous stream for 5 seconds.

- Blow compressed air regulated to 5 to 9 kg/cm2 (70 to 130 psi) through each steel line from the cooler side back toward the transaxle for 10 seconds to force out any remaining CVT fluid.

- Ensure all debris is removed from the steel cooler lines.

- Ensure all debris is removed from the banjo bolts and fittings.

- Perform “CVT FLUID COOLER DIAGNOSIS PROCEDURE”.

CVT FLUID COOLER DIAGNOSIS PROCEDURE

NOTE: Insufficient cleaning of the cooler inlet hose exterior may lead to inaccurate debris identification.

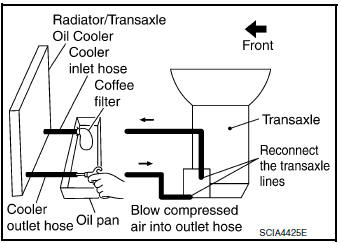

- Position an oil pan under the transaxle's inlet and outlet cooler hoses.

- Clean the exterior and tip of the cooler inlet hose.

- Insert the extension adapter hose of a can of Transmission Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler outlet hose.

CAUTION:

- Wear safety glasses and rubber gloves when spraying the Transmission Cooler Cleaner.

- Spray Transmission Cooler Cleaner only with adequate ventilation.

- Avoid contact with eyes and skin.

- Never breath vapors or spray mist.

- Hold the hose and can as high as possible and spray Transmission Cooler Cleaner in a continuous stream into the cooler outlet hose until CVT fluid flows out of the cooler inlet hose for 5 seconds.

- Tie a common white, basket-type coffee filter to the end of the cooler inlet hose.

- Insert the tip of an air gun into the end of the cooler outlet hose.

- Wrap a shop rag around the air gun tip and end of cooler outlet hose.

- Blow compressed air regulated to 5 to 9 kg/cm2 (70 to 130 psi) through the cooler outlet hose to force any remaining CVT fluid into the coffee filter.

- Remove the coffee filter from the end of the cooler inlet hose.

- Perform “CVT FLUID COOLER INSPECTION PROCEDURE”.

CVT FLUID COOLER INSPECTION PROCEDURE

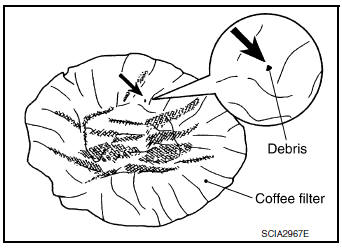

- Inspect the coffee filter for debris.

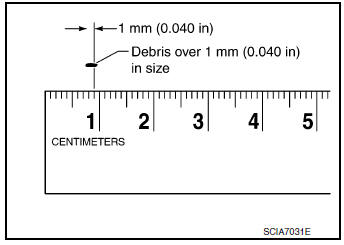

- If small metal debris less than 1 mm (0.040 in) in size or metal powder is found in the coffee filter, this is normal. If normal debris is found, the CVT fluid cooler/radiator can be reused and the procedure is ended.

- If one or more pieces of debris are found that are over 1 mm (0.040 in) in size and/or peeled clutch facing material is found in the coffee filter, the fluid cooler is not serviceable. The radiator/ fluid cooler must be replaced and the inspection procedure is ended.

CVT FLUID COOLER FINAL INSPECTION

After performing all procedures, ensure that all remaining oil is cleaned from all components.

Additional service when replacing TCM and transaxle assembly

Additional service when replacing TCM and transaxle assembly

Description

When replacing TCM and transaxle assembly simultaneously, perform the

following work.

TCM PROGRAMMING

Since vehicle specifications are not yet written in a new TCM, it

i ...

Stall test

Stall test

Work Procedure

INSPECTION

Check the engine oil level. Replenish if necessary. Refer to LU-7,

"Inspection".

Check for leak of the CVT fluid. Refer to TM-190, "Inspe ...

Other materials:

Diagnosis system (BCM) (without intelligent key system)

COMMON ITEM

COMMON ITEM : CONSULT Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

Direct Diagnostic Mode

Description

Ecu Identification

The BCM part number is displayed.

Self Diagnostic ...

Basic inspection

DIAGNOSIS AND REPAIR WORK FLOW

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.GET INFORMATION FOR SYMPTOM

Get detailed information from the customer about the symptom (the

condition and the environment when

the incident/malfunction occurs).

Check operation condition of the ...

P1568 signal invalid

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P1568

ICC COMMAND VALUE

(Intelligent cruise control command value)

ECM detects that a throttle valve opening angle request signal sent

from

...