Nissan Rogue Service Manual: Compression pressure

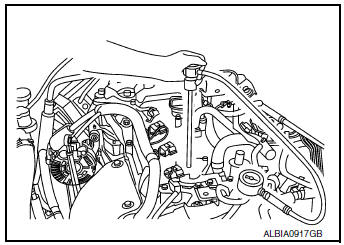

CHECKING COMPRESSION PRESSURE

- Warm up the engine to full operating temperature.

- Release the fuel pressure. Refer to EC-144, "Work Procedure".

- Remove the ignition coil and spark plug from each cylinder. Refer to EM-36, "Removal and Installation" and EM-17, "Removal and Installation".

- Connect engine tachometer (not required in use of CONSULT).

- Disconnect the fuel injector harness connector to avoid any residual fuel injection during the measurement.

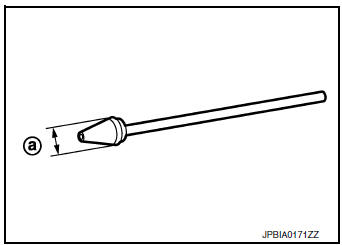

- Install the compression tester with the adapter into the spark plug hole.

- Use compression tester whose end (a) (rubber portion) is smaller than 20 mm (0.79 in) in diameter. Otherwise, it may be caught by cylinder head during removal.

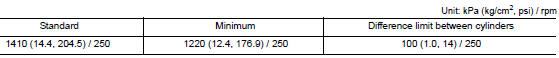

- With the accelerator pedal fully depressed, turn the ignition switch to the “START” position to crank over the engine. When the gauge pointer stabilizes, read the compression pressure and engine rpm. Perform these steps to check each cylinder.

CAUTION: Always use a fully charged battery to obtain specified engine cranking speed.

- If the engine speed is out of specified rpm range, check the battery. Check engine speed again with a fully charged battery.

- If compression pressure is below minimum value, check valve

clearances and parts associated with combustion

chamber (valve, valve seat, piston, piston ring, cylinder bore, cylinder

head, cylinder head gasket).

After the checking, measure compression pressure again.

- If some cylinders have low compression pressure, pour small amount of engine oil into the spark plug hole of the cylinder to re-check it for compression.

- If the added engine oil improves the compression, the piston rings may be worn or damaged. Check the piston rings and replace if necessary.

- If the compression pressure remains at low level despite the

addition of engine oil, the valves may be malfunctioning.

Check the valves for damage. Replace the valve or valve seat accordingly.

- If two adjacent cylinders have respectively low compression pressure and their compression remains low even after the addition of engine oil, the head gasket is leaking. In such a case, replace the cylinder head gasket.

- Install spark plug, ignition coil and harness connectors. Refer to EM-17, "Removal and Installation".

Camshaft valve clearance

Camshaft valve clearance

Camshaft valve clearance

Perform this inspection as follows after removal, installation, or

replacement of the camshaft or any valve

parts, or if there are any unusual engine conditions due t ...

Other materials:

B0091 front side air bag satellite sensor LH

Description

DTC B0091 FRONT SATELLITE SENSOR LH

The front side air bag satellite sensor LH is wired to the air bag diagnosis

sensor unit. The air bag diagnosis

sensor unit will monitor the front side air bag satellite sensor LH for internal

failures and its circuits for communication

errors. ...

P0717 input speed sensor A

DTC Description

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P0717

INPUT SPEED SENSOR A

(Input/Turbine Speed Sensor “A” Circuit No

Signal)

When 1 is satisfied and any of 2, 3 or 4 is satisfied:

W ...

Wheel sensor

FRONT WHEEL SENSOR

FRONT WHEEL SENSOR : Exploded View

Front LH wheel sensor

Harness connector

Slant line

FRONT WHEEL SENSOR : Removal and Installation

CAUTION:

Be careful not to damage front wheel sensor edge and sensor

rotor teeth.

When removing the front ...