Nissan Rogue Service Manual: C1121, C1123, C1125, C1127 ABS out valve system

DTC Logic

DTC DETECTION LOGIC

| DTC | Display Item | Malfunction detected condition | Possible causes |

| C1121 | FR LH OUT ABS SOL | When a malfunction is detected in front LH ABS OUT valve. |

|

| C1123 | FR RH OUT ABS SOL | When a malfunction is detected in front RH ABS OUT valve. | |

| C1125 | RR LH OUT ABS SOL | When a malfunction is detected in rear LH ABS OUT valve. | |

| C1127 | RR RH OUT ABS SOL | When a malfunction is detected in rear RH ABS OUT valve. |

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT.

With CONSULT.

- Turn ignition switch OFF to ON.

- Perform self-diagnostic result.

Is DTC C1121, C1123, C1125 or C1127 detected? YES >> Proceed to diagnosis procedure. Refer to BRC-89, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to BRC-57, "Wiring Diagram".

1.CONNECTOR INSPECTION

- Turn ignition switch OFF.

- Disconnect ABS actuator and electric unit (control unit) connectors.

- Check connectors and terminals for deformation, disconnection, looseness or damage.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace as necessary.

2.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) BATTERY POWER SUPPLY

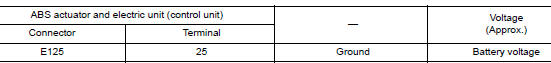

Check voltage between ABS actuator and electric unit (control unit) connector E125 terminal 25 and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace malfunctioning components.

3.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) GROUND CIRCUIT

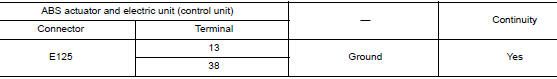

Check continuity between ABS actuator and electric unit (control unit) connector E125 terminals 13, 38 and ground.

Is the inspection result normal? YES >> Replace ABS actuator and electric unit (control unit). Refer to BRC-136, "Removal and Installation".

NO >> Repair or replace malfunctioning components.

C1120, C1122, C1124, C1126 ABS in valve system

C1120, C1122, C1124, C1126 ABS in valve system

DTC Logic

DTC DETECTION LOGIC

DTC

Display Item

Malfunction detected condition

Possible causes

C1120

FR LH IN ABS SOL

When a malfunction is detected in front LH ABS IN

...

C1130 engine signal

C1130 engine signal

DTC Logic

DTC DETECTION LOGIC

DTC

Display Item

Malfunction detected condition

Possible causes

C1130

ENGINE SIGNAL 1

When a malfunction is detected in ECM system.

...

Other materials:

Regulatory Information

FCC Regulatory information

CAUTION: To maintain compliance with

FCC’s RF exposure guidelines, use only the

supplied antenna. Unauthorized antenna,

modification, or attachments could damage

the transmitter and may violate FCC regulations.

Operation is subject to the follow ...

Periodic maintenance

FRONT SUSPENSION ASSEMBLY

Inspection

COMPONENT

Check the conditions (looseness, backlash) of each component. Verify the

component conditions (wear, damage)

are normal.

Ball Joint Axial End Play

Set front wheels in a straight-ahead position.

Move axle side of transverse link, ...

Periodic maintenance

REAR PROPELLER SHAFT

Inspection

APPEARANCE AND NOISE

Check the propeller shaft tube surface for dents or cracks. If

malfunction is detected, replace propeller shaft

assembly.

If center bearing is noisy or damaged, replace propeller shaft

assembly.

VIBRATION

If vibrati ...