Nissan Rogue Service Manual: Brake booster

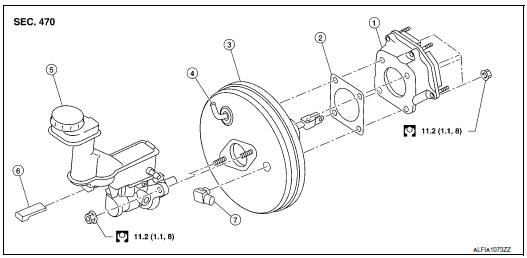

Exploded View

- Spacer

- Gasket

- Brake booster

- Check valve

- Reservoir tank

- Brake fluid level sensor

- Brake booster pressure sensor

Removal and installation

REMOVAL

- Remove the cowl top. Refer to EXT-25, "Removal and Installation".

- Remove the instrument lower panel LH. Refer to IP-22, "Removal and Installation".

- Remove the knee protector. Refer to IP-14, "Exploded View".

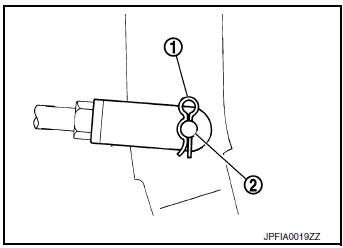

- Remove the snap pin (1) and clevis pin (2) from the brake pedal.

- Disconnect vacuum hose from brake booster. Refer to BR-32, "Exploded View".

- Remove master cylinder assembly. Refer to BR-27, "Removal and Installation".

- Disconnect the harness connector from the brake booster pressure sensor.

- Remove the brake booster pressure sensor.

- Remove the nuts on the brake booster and brake pedal.

CAUTION: Secure the brake booster to avoid damage to components.

- Remove the brake booster.

CAUTION: Do not deform or bend the brake pipes.

INSTALLATION

- Install a new gasket between the brake booster and dash panel.

CAUTION: Do not reuse the gasket.

- Install the brake booster to the dash panel from the engine room

side.

CAUTION: Do not damage brake booster stud bolt threads during installation.

- Install the nuts to the brake booster and brake pedal. Refer to BR-30, "Exploded View".

- Install the brake booster pressure sensor.

- Connect the harness connector to the brake booster pressure sensor.

- Install master cylinder assembly. Refer to BR-27, "Removal and Installation".

- Connect vacuum hose to brake booster. Refer toBR-32, "Exploded View".

- Install the clevis pin and snap pin to the brake pedal.

- Adjust the brake pedal. Refer to BR-15, "Adjustment".

- Install the knee protector. Refer to IP-14, "Exploded View".

- Install instrument lower panel LH. Refer to IP-22, "Removal and Installation".

- Bleed the brake system. Refer to BR-16, "Bleeding Brake System".

- Inspect the brake booster. Refer to BR-10, "Inspection".

Brake master cylinder

Brake master cylinder

Exploded View

Reservoir cap

Oil strainer

Reservoir tank

Brake fluid level sensor

Cylinder body

Pin

O-ring

Grommet

: Apply PBC (Poly Butyl

Cuprysil) grease or sil ...

Vacuum lines

Vacuum lines

Exploded View

Clamp

Vacuum hose

Vacuum tube

Clip

Vacuum hose

To intake manifold

To brake booster

Paint mark

Stamp indicating engine direction

Removal an ...

Other materials:

Preparation

Commercial Service Tool

Tool name

Description

Brake drum clearance gauge

Measuring rear rotor drum inner diamete

Power tool

Loosening nuts, screws and bolts

...

Preparation

Special Service Tools

The actual shape of the tools may differ from those illustrated here.

Tool number

(Kent-Moore No.)

Tool name

Description

(J-44321)

Fuel pressure gauge

kit

Checks fuel pressure

KV10120000

Fuel tube adapter

...

Low tire pressure warning lamp

Component Function Check

1.CHECK THE ILLUMINATION OF THE LOW TIRE PRESSURE WARNING LAMP

Check that the low tire pressure warning lamp is turned OFF after

illuminating for approximately 1 second,

when the ignition switch is turned ON.

Is the inspection result normal?

YES >> Inspection ...