Nissan Rogue Service Manual: Basic inspection

DIAGNOSIS AND REPAIR WORK FLOW

Work Flow

DETAILED FLOW

1.INTERVIEW FROM THE CUSTOMER

Clarify customer complaints before inspection. First of all, perform an interview utilizing DLN-32, "Diagnostic Work Sheet" and reproduce symptoms as well as fully understand it. Ask customer about his/her complaints carefully. Check symptoms by driving vehicle with customer, if necessary.

CAUTION: Customers are not professional. Never guess easily like ÔÇťmaybe the customer means that...,ÔÇŁ or ÔÇťmaybe the customer mentions this symptomÔÇŁ. >> GO TO 2.

2.CHECK SYMPTOM

Reproduce the symptom that is indicated by the customer, based on the information from the customer obtained by interview. Also check that the symptom is not caused by protection function. Refer to DLN-22, "Protection Function".

CAUTION: When the symptom is caused by normal operation, fully inspect each portion and obtain the understanding of customer that the symptom is not caused by a malfunction.

>> GO TO 3.

3.PERFORM SELF-DIAGNOSIS

With CONSULT

With CONSULT

Perform self-diagnosis for ÔÇťALL MODE AWD/4WDÔÇŁ.

Is any DTC detected? YES >> Record or print self-diagnosis results. GO TO 4.

NO >> GO TO 6.

4.RECHECK SYMPTOM

With CONSULT

With CONSULT

- Erase self-diagnostic results for ÔÇťALL MODE AWD/4WDÔÇŁ.

- Perform DTC confirmation procedures for the error detected system.

NOTE: If some DTCs are detected at the same time, determine the order for performing the diagnosis based on DLN- 22, "DTC Inspection Priority Chart". Is any DTC detected? YES >> GO TO 5.

NO >> Check harness and connectors based on the information obtained by interview. Refer to GI-41, "Intermittent Incident".

5.REPAIR OR REPLACE ERROR-DETECTED PARTS

- Repair or replace error-detected parts.

- Reconnect part or connector after repairing or replacing.

- When DTC is detected, erase self-diagnostic results for ÔÇťALL MODE AWD/4WDÔÇŁ.

>> GO TO 7.

6.IDENTIFY ERROR-DETECTED SYSTEM BY SYMPTOM DIAGNOSIS

Estimate error-detected system based on symptom diagnosis and perform inspection.

Can the error-detected system be identified?

YES >> GO TO 7.

NO >> Check harness and connectors based on the information obtained by interview. Refer to GI-41, "Intermittent Incident".

7.FINAL CHECK

With CONSULT

With CONSULT

- Check the reference value for AWD control module.

- Recheck the symptom and check that symptom is not reproduced on the same conditions.

Is the symptom reproduced? YES >> GO TO 3.

NO >> INSPECTION END

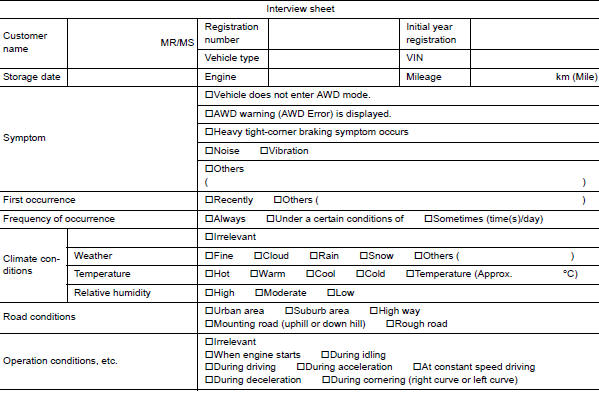

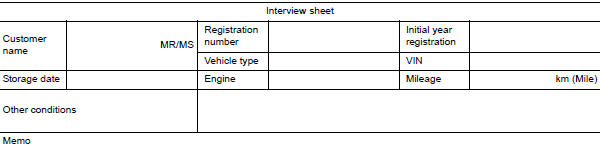

Diagnostic Work Sheet

Description

- In general, customers have their own criteria for a problem. Therefore, it is important to understand the symptom and status well enough by asking the customer about his/her concerns carefully. To systemize all the information for the diagnosis, prepare the interview sheet referring to the interview points.

- In some cases, multiple conditions that appear simultaneously may cause a DTC to be detected.

Interview sheet sample

ADDITIONAL SERVICE WHEN REPLACING AWD CONTROL UNIT

Description

When replacing AWD control unit, unit characteristics writing is required.

Work Procedure

1.PERFORM WRITING UNIT CHARACTERISTICS

Perform writing unit characteristics of electric controlled coupling.

>> Refer to DLN-35, "Work Procedure".

UNIT CHARACTERISTICS WRITING

Description

When replacing AWD control unit, rear final drive assembly and/or electric controlled coupling, unit characteristics of electric controlled coupling writing is required.

Work Procedure

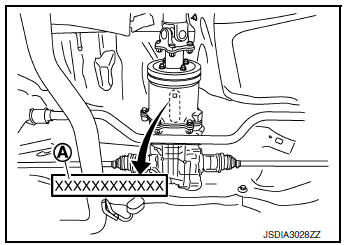

1.UNIT CHARACTERISTICS WRITING

With CONSULT

With CONSULT

- Confirm the unit characteristics Aof electric controlled coupling.

NOTE: Unit characteristics is 12-digit alphanumeric.

- Turn the ignition switch OFF to ON.

- Select ÔÇťUNIT CHARACTERISTICS WRITEÔÇŁ in ÔÇťWORK SUPPORTÔÇŁ for ÔÇťALL MODE AWD/4WDÔÇŁ.

- Input unit characteristics.

- Select ÔÇťStartÔÇŁ.

- Check that ÔÇťUNIT CHARACTERISTICS WRITE COMPLETEDÔÇŁ is displayed.

>> WORK END

Wiring diagram

Wiring diagram

AWD SYSTEM

Wiring Diagram

...

DTC/Circuit diagnosis

DTC/Circuit diagnosis

C1201 AWD CONTROL UNIT

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

C1201

CONTROLLER FAILURE

( ...

Other materials:

Manual control

While using the Voice Recognition system, it is

possible to select menu options by using the

steering wheel controls instead of speaking voice

commands. To activate manual control mode,

press the PHONE/SEND ( ) button on

the

steering wheel to access the phone menu and

then press either u ...

Servicing air conditioner

The air conditioner system in your NISSAN vehicle

is charged with a refrigerant designed with

the environment in mind.

This refrigerant does not harm the earthÔÇÖs

ozone layer.

Special charging equipment and lubricant is required

when servicing your NISSAN air conditioner.

Using improper ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as ÔÇťAIR BAGÔÇŁ and ÔÇťSEAT BELT PRE-TENSIONERÔÇŁ,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

...