Nissan Rogue Service Manual: Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

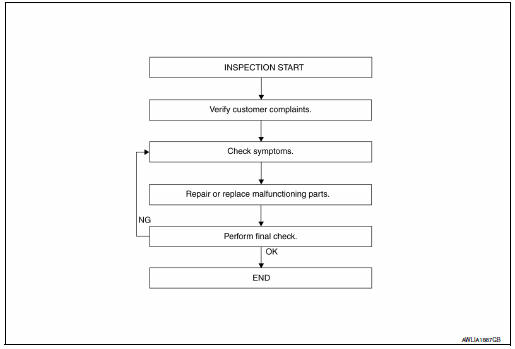

Work Flow

WORK FLOW

DETAILED FLOW

1. REVIEW CUSTOMER COMPLAINT

Review customer complaint. Try to obtain detailed information about the conditions when the symptom occurs.

>> GO TO 2.

2. VERIFY THE SYMPTOM

Verify the symptom by performing an operational check. Refer to WW-8, "FRONT WIPER AND WASHER SYSTEM : System Description".

>> GO TO 3.

3.PERFORM TROUBLE DIAGNOSIS BY SYMPTOM

Diagnose the vehicle by performing the appropriate trouble diagnosis. Refer to WW-50, "Symptom Table".

>> GO TO 4.

4. REPAIR OR REPLACE MALFUNCTIONING PARTS

Repair or replace the specific parts.

>> GO TO 5.

5. FINAL CHECK

Perform a final inspection of the system.

Is the inspection result normal? YES >> Inspection End.

NO >> GO TO 2.

Rear wiper and washer system

Rear wiper and washer system

Wiring Diagram

...

Other materials:

How to use the vehicle information display

The vehicle information display can be changed

using the buttons and ENTER located

on

the steering wheel.

— navigate through the

items in vehicle

information

ENTER — change or select an item in the

vehicle information display

— select/enter the

Vehicle i ...

System description

COMPONENT PARTS

Component Parts Location

Instrument lower panel LH

Rear final drive assembly

Rear wheel house outer panel in luggage

room of left side

No.

Component

Function

1

Combination meter

Mainly transmits the following signals to AWD control unit ...

Precautions when starting and driving

WARNING

Do not leave children or adults who

would normally require the assistance

of others alone in your vehicle. Pets

should also not be left alone. They

could accidentally injure themselves or

others through inadvertent operation of

the vehicle. Also, on h ...