Nissan Rogue Service Manual: Third row seat

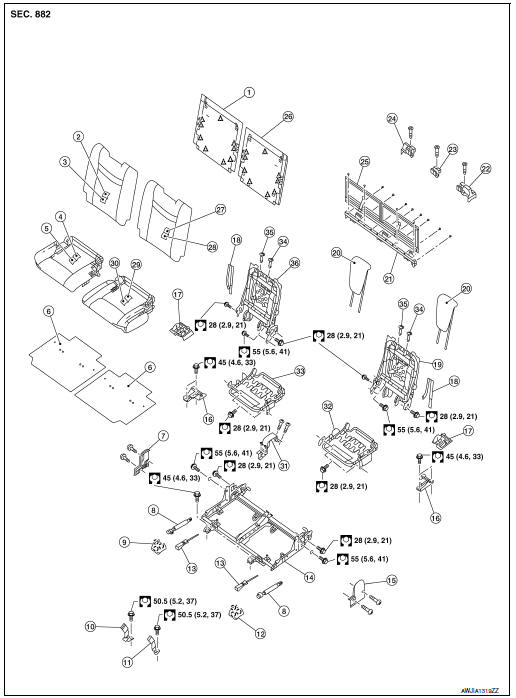

Exploded View

- Seatback board (RH)

- Seatback trim (RH)

- Seatback pad (RH)

- Seat cushion trim (RH)

- Seat cushion pad (RH)

- Seat cushion silencer (LH/RH)

- Seat hinge finisher (RH)

- Gas stay

- Bolt cover (RH)

- Seat belt buckle (RH)

- Seat belt buckle (LH)

- Bolt cover (LH)

- Stopper pin

- Seat frame support

- Seat hinge finisher (LH)

- Seat striker (LH/RH)

- Seat striker finisher (LH/RH)

- Seatback pull strap (LH/RH)

- Seatback frame (LH)

- Headrest (LH/RH)

- Third row seat cross member

- Third row seat cross member finisher (LH)

- Third row seat cross member finisher (center)

- Third row seat cross member finisher (RH)

- Third row luggage floor

- Seatback board (LH)

- Seatback trim (LH)

- Seatback pad (LH)

- Seat cushion trim (LH)

- Seat cushion pad (LH)

- Seat frame finisher (center)

- Seat cushion frame (LH)

- Seat cushion frame (RH))

- Headrest holder (locked)

- Headrest holder (free)

- Seatback frame (RH)

Clip

Clip

Pawl

Pawl

Seatback

DISASSEMBLY

NOTE: LH shown : RH similar

- Remove third row seat. Refer to SE-43, "Removal and Installation".

- Remove headrest.

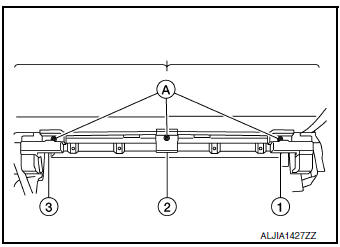

- Remove screws (A) and third row seat cross member finishers (1, 2, 3).

- Release seatback pull strap stop using a suitable tool.

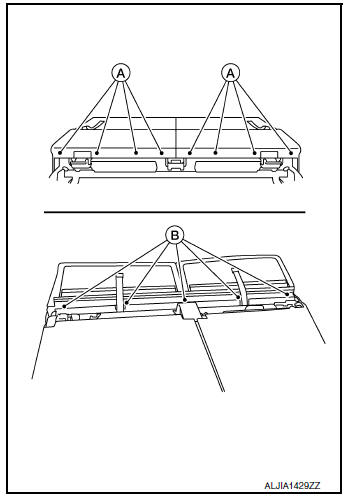

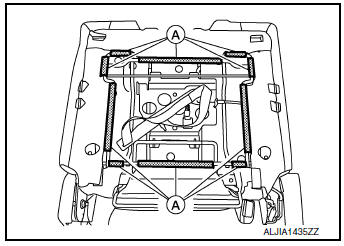

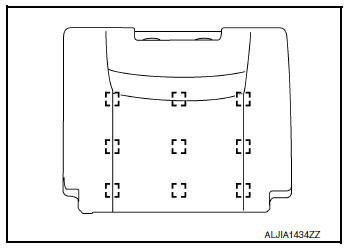

- Release third row luggage board outer clips (A) and inner clips (B) using a suitable tool.

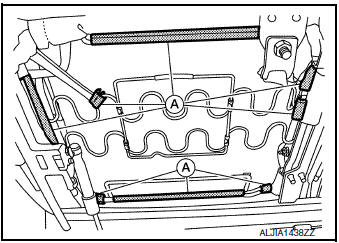

- Release third row luggage board retainer strap clips (A) (LH/RH) using a suitable tool and remove third row luggage board.

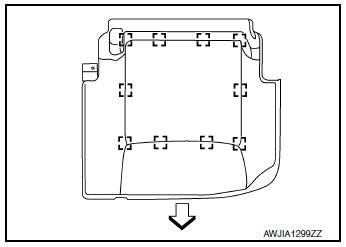

- Release clips using a suitable tool then gently pull seatback

board (1) forward and out and remove as shown (

).

).

CAUTION:

After removing the seatback board, check the orientation of

clips. Improper installation of clips could result in damage

to the seatback board.

: Clip

: Clip

- Reinstall clips in proper locations on the seatback board.

- Remove screws (A) and remove seat hinge finisher (1).

- Release J-hooks from seat frame and remove seatback trim and seatback pad as an assembly.

- Reach up behind the seatback pad, release the headrest holder

locks as shown and remove the headrest holders.

CAUTION: Before removing/installing headrest holder, check its orientation (front/rear and right/left).

- Release hook and loop finisher and remove hog rings, then separate

seatback trim from seatback pad.

NOTE: Remove all pieces of hog rings and discard them.

: Hog ring

: Hog ring

ASSEMBLY

Assembly is in the reverse order of disassembly.

- Install new hog rings on the seatback trim in original positions.

- Use only one hog ring in each designated location.

- Make sure hog rings are correctly fastened around both the seatback trim and seatback pad wires.

- Use NISSAN standard hog rings and tools to assemble.

- Make sure hook fastener is pressed into place after seatback trim is assembled.

- Smooth out all wrinkles during assembly.

Seat Cushion

DISASSEMBLY

NOTE:

- Remove third row seat. Refer to SE-43, "Removal and Installation".

- Remove third row seat cross member. Refer to SE-44, "Third Row Seat Cross Member".

- Using a suitable tool, release seat cushion trim clips (A) and

remove rear screws (B). Then, release metal clip and remove

the center seat frame finisher (1).

: Metal clip

: Metal clip

: Front

: Front

- Release J-hooks (A) from seat frame and remove seat cushion trim and seat cushion pad.

- Remove hog rings and separate the seat cushion trim from the

seat cushion pad.

NOTE: Remove all pieces of hog rings and discard them.

: Hog ring

: Hog ring

: Front

: Front

ASSEMBLY

Assembly is in the reverse order of disassembly.

- Install new hog rings on the seat cushion trim in original positions.

- Use only one hog ring in each designated location.

- Make sure hog rings are correctly fastened around both the seat cushion trim and seat cushion pad wires.

- Use NISSAN standard hog rings and tools to assemble.

- Make sure hook fastener is pressed into place after seat cushion trim is assembled.

- Smooth out all wrinkles during assembly.

Second row seat

Second row seat

Exploded View

RH SEAT

Headrest

Seatback upper luggage

board

Seatback luggage board

Seatback trim

Seatback pad

Recline release cable

Seat cushion trim

Fold flat strap ...

Other materials:

Component parts

Component Parts Location

Combination meter

Engine room right side

Engine room left side

No.

Component part

Description

1

Combination meter (Charge warning lamp)

The IC regulator warning function activates to illuminate the charge

warning

...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

...

B1430 seat belt pre-tensioner

DTC Logic

DTC DETECTION LOGIC

CONSULT name

DTC

DTC detecting condition

Repair order

FRONT PRE-TEN LH CIRCUIT

[OPEN]

B1430

Front LH seat belt pre-tensioner circuit is

open.

Refer to SRC-59, "Diagnosis Procedure".

FRONT PRE-T ...