Nissan Rogue Service Manual: P2100, P2103 throttle control motor relay

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| P2100 | ETC MOT PWR-B1 (Throttle actuator ″A″ control motor circuit/ open) | ECM detects a voltage of power source for throttle control motor is excessively low. |

| P2103 | ETC MOT PWR-B1 (Throttle actuator ″A″ control motor circuit high) | ECM detect the throttle control motor relay is stuck ON. |

POSSIBLE CAUSE

DTC P2100

- Harness or connectors (Throttle control motor relay circuit is open.)

- Throttle control motor relay

DTC P2103

- Harness or connectors (Throttle control motor relay circuit is shorted.)

- Throttle control motor relay

FAIL-SAFE

ECM stops the electric throttle control actuator control, throttle valve is maintained at a fixed opening (approx.

5 degrees) by the return spring.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION: Before performing the following procedure, confirm that battery voltage is more than 8 V.

Witch DTC is detected? P2100 >> GO TO 2.

P2103 >> GO TO 3.

2.PERFORM DTC CONFIRMATION PROCEDURE FOR DTC P2100

- Turn ignition switch ON and wait at least 2 seconds.

- Start engine and let it idle for 5 seconds.

- Check DTC.

Is DTC detected? YES >> Proceed to EC-431, "Diagnosis Procedure".

NO >> INSPECTION END

3.PERFORM DTC CONFIRMATION PROCEDURE FOR DTC P2103

- Turn ignition switch ON and wait at least 1 second.

- Check DTC.

Is DTC detected? YES >> Proceed to EC-431, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

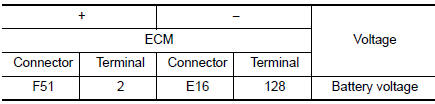

1.CHECK THROTTLE CONTROL MOTOR RELAY POWER SUPPLY

- Turn ignition switch OFF.

- Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

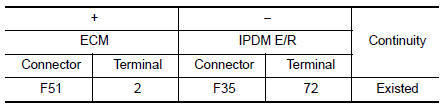

2.CHECK THROTTLE CONTROL MOTOR RELAY POWER SUPPLY CIRCUIT

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector.

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

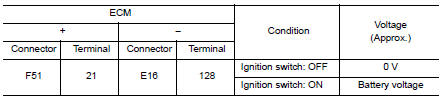

3.CHECK THROTTLE CONTROL MOTOR RELAY INPUT SIGNAL

Check the voltage between ECM harness connector and ground as per the following conditions.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

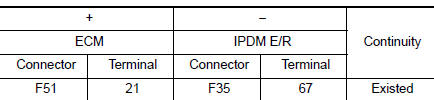

4.CHECK THROTTLE CONTROL MOTOR RELAY INPUT SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector.

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> INSPECTION END

P2096, P2097 A/F sensor 1

P2096, P2097 A/F sensor 1

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P2096

POST CATALYST FUEL TRIM SYS B1

(Post catalys ...

P2101 electric throttle control function

P2101 electric throttle control function

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P2101

ETC FNCTN/CIRC-B1

(Throttle actuator ″ ...

Other materials:

Bluetooth® Hands-Free Phone System with Navigation System (if so equipped)

WARNING

Use a phone after stopping your vehicle

in a safe location. If you have to use a

phone while driving, exercise extreme

caution at all times so full attention may

be given to vehicle operation.

If you are unable to devote full attention

to vehicl ...

P0196 EOT sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0196

EOT SENSOR

(Engine oil temperature sensor range/performance)

A

Rationally incorrect voltage from the sensor is sent to ECM,

compared

...

P084c transmission fluid pressure SEN/SW H

DTC Description

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P084C

FLUID PRESS SEN/SW H

(Transmission Fluid Pressure Sensor/Switch H

Circuit Low)

When all of the following conditions are satisfied and this sta ...