Nissan Rogue Service Manual: P0132 A/F sensor 1

DTC Description

DTC DETECTION LOGIC

To judge the malfunction, the diagnosis checks that the A/F signal computed by ECM from the A/F sensor 1 signal is not inordinately high.

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| P0132 | A/F SENSOR1 (B1) (O2 sensor circuit high voltage bank 1 sensor 1) | The A/F signal computed by ECM from the A/F sensor 1 signal is constantly approx. 5 V. |

POSSIBLE CAUSE

- Harness or connectors (A/F sensor 1 circuit is open or shorted.)

- A/F sensor 1

FAIL-SAFE

Not applicable

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION: Before performing the following procedure, confirm that battery voltage is more than 10.5 V at idle.

>> GO TO 2.

2.CHECK A/F SENSOR FUNCTION

With CONSULT

With CONSULT

- Start engine and warm it up to normal operating temperature.

- Select “A/F SEN1 (B1)” in “DATA MONITOR” mode of “ENGINE” using CONSULT.

- Check “A/F SEN1 (B1)” indication.

With GST

With GST

Follow the procedure “With CONSULT” above.

Is the indication constantly approx. 5 V? YES >> Proceed to EC-234, "Diagnosis Procedure".

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

- Turn ignition switch OFF, wait at least 10 seconds and then restart engine.

- Drive and accelerate vehicle to more than 40 km/h (25 MPH) within

20 seconds after restarting engine.

CAUTION: Always drive vehicle at a safe speed.

- Maintain the following conditions for about 20 consecutive seconds.

| ENG SPEED | 1,000 - 3,200 rpm |

| VHCL SPEED SE | More than 40 km/h (25 mph) |

| B/FUEL SCHDL | 1.5 - 9.0 msec |

| Selector lever | Suitable position |

NOTE:

- Keep the accelerator pedal as steady as possible during the cruising.

- If this procedure is not completed within 1 minute after restarting engine at step 1, return to step 1.

- Check 1st trip DTC.

With GST

With GST

Follow the procedure “With CONSULT” above.

Is 1st trip DTC is detected? YES >> Proceed to EC-234, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

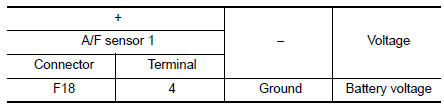

1.CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect A/F sensor 1 harness connector.

- Turn ignition switch ON.

- Check the voltage between A/F sensor 1 harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

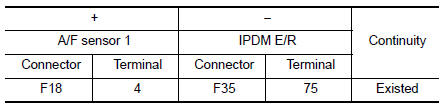

2.CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect IPDM E/R harness connector.

- Check the continuity between A/F sensor 1 harness connector and IPDM E/R harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

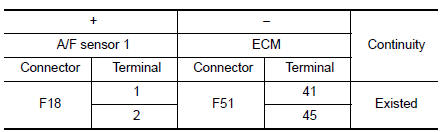

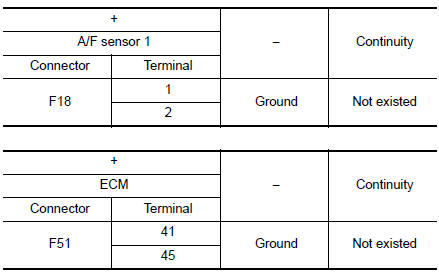

3.CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

- Check the continuity between A/F sensor 1 harness connector and ground, or ECM harness connector and ground.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK INTERMITTENT INCIDENT

Perform GI-41, "Intermittent Incident".

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.REPLACE AIR FUEL RATIO (A/F) SENSOR 1

place air fuel ratio (A/F) sensor 1. Refer to EM-29, "Exploded View".

CAUTION:

- Discard any sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a hard surface such as a concrete floor; use a new one.

- Before installing new sensor, clean exhaust system threads using Oxygen Sensor Thread Cleaner [commercial service tool (J-43897-18 or J43897-12)] and approved Anti-seize Lubricant (commercial service tool).

>> INSPECTION END

P0131 A/F sensor 1

P0131 A/F sensor 1

DTC Description

DTC DETECTION LOGIC

To judge the malfunction, the diagnosis checks that the A/F signal computed

by ECM from the A/F sensor 1

signal is not inordinately low.

DTC No.

CON ...

P0137 HO2S2

P0137 HO2S2

DTC Description

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the air fuel ratio (A/F) sensor 1. The oxygen

storage capacity of the thr ...

Other materials:

Diagnosis system (BCM) (with intelligent key system)

COMMON ITEM

COMMON ITEM : CONSULT Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

Direct Diagnostic Mode

Description

Ecu Identification

The BCM part number is displayed.

Self Diagnostic ...

EVAP canister filter

Exploded View

EVAP canister vent control valve hose

Canister drain hose

Plug

EVAP canister filter

Front

Removal and Installation

REMOVAL

Disconnect EVAP canister vent control valve hose from EVAP

canister filter.

Disconnect canister drain hose from E ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

...