Nissan Rogue Service Manual: P0117, P0118 ECT sensor

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| P0117 | ECT SEN/CIRC (Engine coolant temperature sensor 1 circuit low) | An excessively low voltage from the engine coolant temperature sensor is sent to ECM. |

| P0118 | ECT SEN/CIRC (Engine coolant temperature sensor 1 circuit high) | An excessively high voltage from the engine coolant temperature sensor is sent to ECM. |

POSSIBLE CAUSE

- Harness or connectors (Engine coolant temperature sensor circuit is open or shorted.)

- Engine coolant temperature sensor

FAIL-SAFE

Not applicable

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON and wait at least 5 seconds.

- Check DTC.

Is DTC detected? YES >> Proceed to EC-213, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

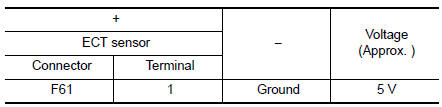

1.CHECK ENGINE COOLANT TEMPERATURE SENSOR POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect engine coolant temperature (ECT) sensor harness connector.

- Turn ignition switch ON.

- Check the voltage between ECT sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

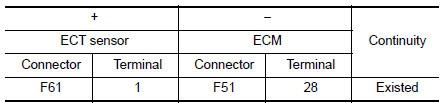

2.CHECK ENGINE COOLANT TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between ECT sensor harness connector and ECM harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

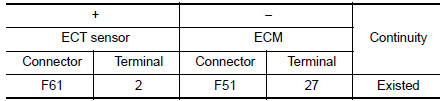

3.CHECK ENGINE COOLANT TEMPERATURE SENSOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between ECT sensor harness connector and ECM harness connector.

- Also check harness for short to ground to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Check the engine coolant temperature sensor. Refer to EC-212, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace engine coolant temperature sensor. Refer to CO-23, "Exploded View".

5.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> INSPECTION END

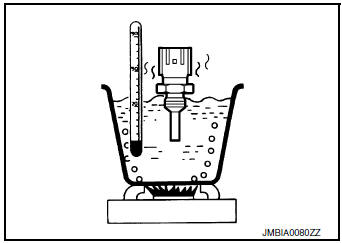

Component Inspection

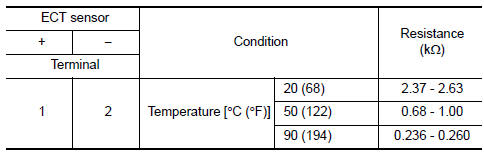

1.CHECK ENGINE COOLANT TEMPERATURE (ECT) SENSOR

- Turn ignition switch OFF.

- Disconnect ECT sensor harness connector.

- Remove ECT sensor.

- Check resistance between ect sensor terminals by heating with hot water as shown in the figure.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace engine coolant temperature sensor. Refer to CO-23, "Exploded View".

P0116 ECT sensor

P0116 ECT sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0116

ECT SENSOR

(Engine coolant temperature senso ...

P0122, P0123 TP sensor

P0122, P0123 TP sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0122

TP SEN 2/CIRC-B1

(Throttle/pedal position se ...

Other materials:

Removal and installation

HOOD

Exploded View

Hood hinge (RH)

Hood

Hood side seal

Hood front seal

Hood center seal

Bumper rubber

Hood insulator

Hood rod clamp

Hood support rod

Hood rod grommet

Hood hinge (LH)

HOOD ASSEMBLY

HOOD ASSEMBLY : Removal and Instal ...

Brake fluid

Drain and Refill

CAUTION:

Do not spill or splash brake fluid on painted surfaces. Brake

fluid may damage paint. If brake fluid is

splashed on painted areas, wash it away with water immediately.

Prior to repair, turn the ignition switch OFF, disconnect the

ABS actuator and ...

Back door window glass

Exploded View

Back door window glass

Clip

Clip

Removal and Installation

REMOVAL

Remove back door finisher. Refer to INT-38, "Removal and

Installation".

Remove back door lock. Refer to DLK-263, "DOOR LOCK : Removal and

Installation" (for i ...