Nissan Rogue Service Manual: P0031, P0032 A/F sensor 1 heater

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| P0031 | A/F SEN1 HTR (B1) [Air fuel ratio (A/F) sensor 1 heater (bank 1)control circuit low] | The current amperage in the A/F sensor 1 heater circuit is out of

the normal

range.

(An excessively low voltage signal is sent to ECM through the A/F sensor 1 heater.) |

| P0032 | A/F SEN1 HTR (B1) [Air fuel ratio (A/F) sensor 1 heater (bank 1)control circuit high] | The current amperage in the A/F sensor 1 heater circuit is out of

the normal

range.

(An excessively high voltage signal is sent to ECM through the A/F sensor 1 heater.) |

POSSIBLE CAUSE

DTC P0031

- Harness or connectors (A/F sensor 1 heater circuit is open or shorted.)

- A/F sensor 1 heater

DTC P0032

- Harness or connectors (A/F sensor 1 heater circuit is shorted.)

- A/F sensor 1 heater

FAIL-SAFE

Not applicable

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION: Before performing the following procedure, confirm that battery voltage is more than between 11 V at idle. >> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and let it idle for at least 10 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-185, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

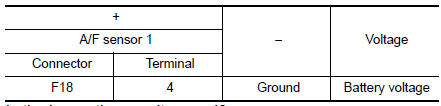

1.CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPLY CIRCUIT

- Disconnect air fuel ratio (A/F) sensor 1 harness connector.

- Turn ignition switch ON.

- Check the voltage between A/F sensor 1 harness connector and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace error-detected parts.

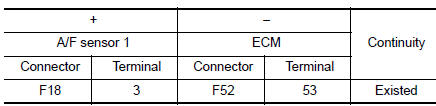

2.CHECK A/F SENSOR 1 HEATER OUTPUT SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

3.CHECK A/F SENSOR 1 HEATER Check the A/F sensor 1 heater. Refer to EC-186, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4.REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace malfunctioning air fuel ratio (A/F) sensor 1. Refer to EM-29, "Exploded View".

CAUTION:

- Discard any A/F sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a hard surface such as a concrete floor; use a new one.

- Before installing new A/F sensor, clean exhaust system threads using Oxygen Sensor Thread Cleaner [commercial service tool (J-43897-18 or J-43897-12)] and approved Anti-seize Lubricant (commercial service tool).

>> INSPECTION END

5.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> INSPECTION END

Component Inspection

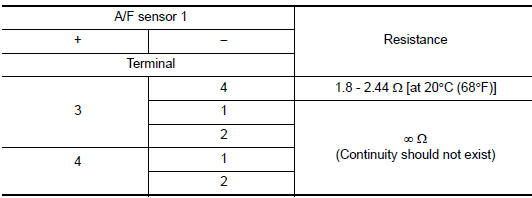

1.CHECK AIR FUEL RATIO (A/F) SENSOR 1

- Turn ignition switch OFF.

- Disconnect A/F sensor 1 harness connector.

- Check resistance between A/F sensor 1 terminals as per the following.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

2.REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace air fuel ratio (A/F) sensor 1. Refer to EM-29, "Exploded View".

CAUTION:

- Discard any sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a hard surface such as a concrete floor; use a new one.

- Before installing new sensor, clean exhaust system threads using Oxygen Sensor Thread Cleaner [commercial service tool (J-43897-18 or J43897-12)] and approved Anti-seize Lubricant (commercial service tool).

>> INSPECTION END

P0014 EVT control

P0014 EVT control

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0014

EXH/V TIM CONT-B1

(″B″ Camshaft ...

P0037, P0038 HO2S2 heater

P0037, P0038 HO2S2 heater

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0037

HO2S2 HTR (B1)

(HO2S heater control circuit ...

Other materials:

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as ŌĆ£AIR BAGŌĆØ and ŌĆ£SEAT BELT PRE-TENSIONERŌĆØ,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

...

P0171 fuel injection system function

DTC Description

DTC DETECTION LOGIC

With the Air/Fuel Mixture Ratio Self-Learning Control, the actual mixture

ratio can be brought closely to the

theoretical mixture ratio based on the mixture ratio feedback signal from the

A/F sensors 1. The ECM calculates

the necessary compensation to corr ...

Changing wheels and tires

Tire rotation

NISSAN recommends rotating the tires

every 7,500 miles (12,000 km).

Refer to ŌĆ£Flat tireŌĆØ in the ŌĆ£In case of emergencyŌĆØ

section in this manual for tire replacing

procedures.

As soon as possible, tighten the

wheel nuts to the specified torque

with a torque wrench.

...